Ultrathin square solid capacitor and manufacturing method thereof

A capacitor and square technology, applied in the field of capacitors, can solve the problems of working electrolyte failure, poor temperature-frequency characteristics, large ESR, etc., and achieve the effects of small equivalent series internal resistance and impedance, strong ripple resistance, and less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

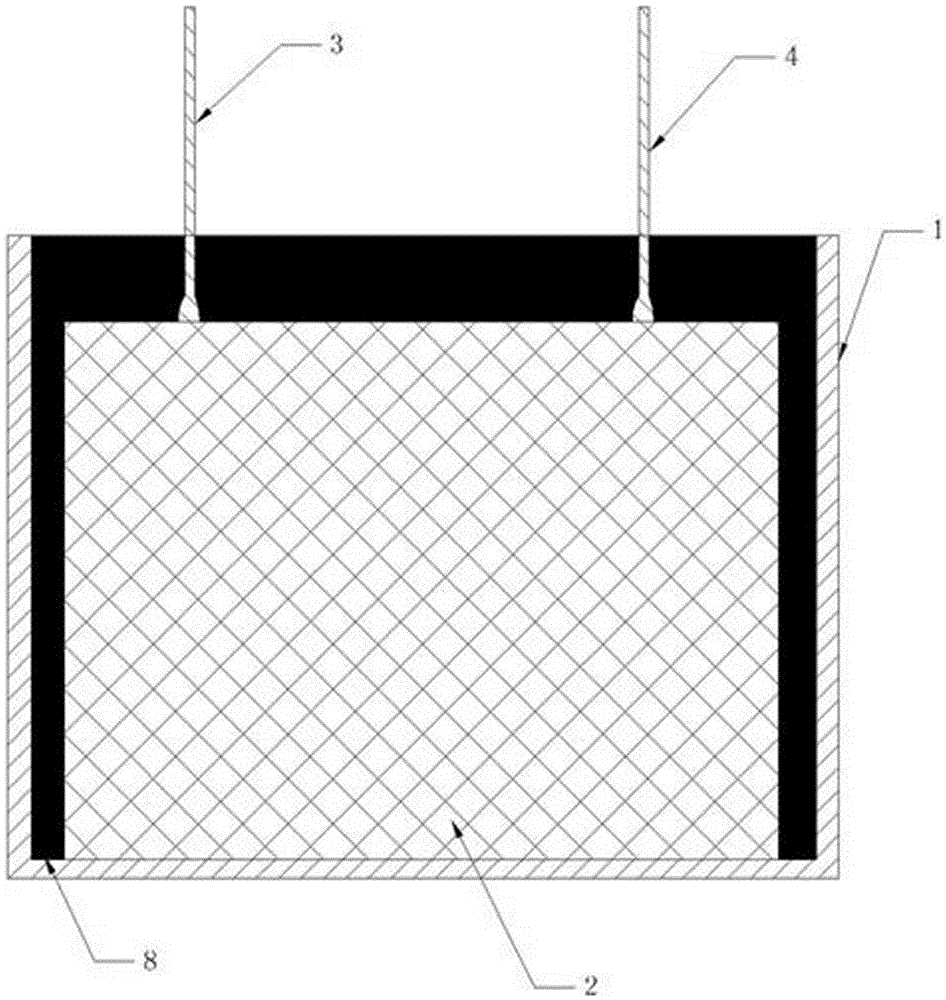

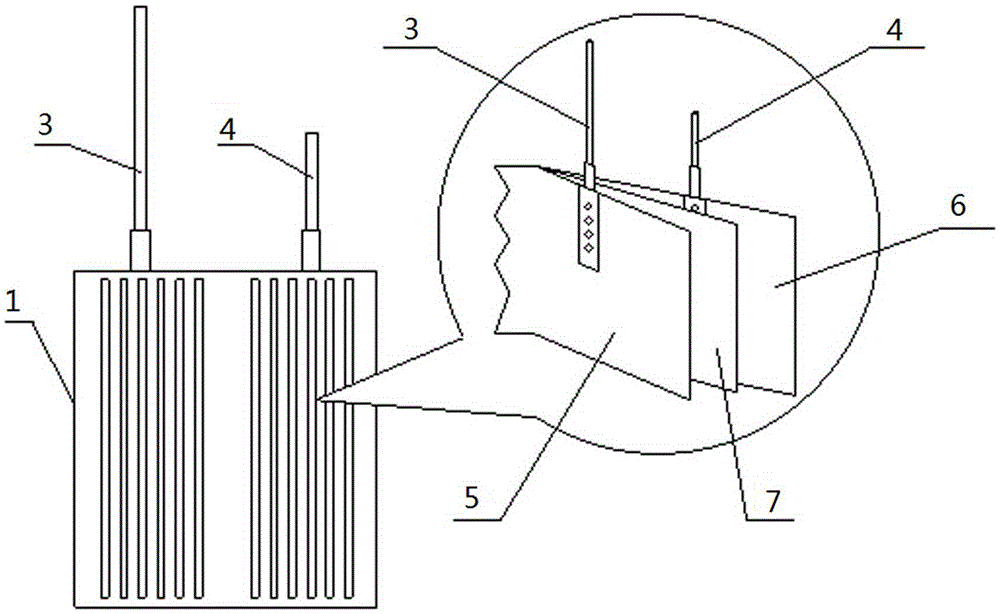

[0030] Such as figure 1 and figure 2 An ultra-thin square solid capacitor is shown, comprising a square steel case 1 with an open end, a flat core package 2 and a fixed filler; the flat core package 2 is fixed in the square steel case 1 by a fixed filler, The thickness of the square steel shell 1 is between 2-5 mm; the core package 2 includes an anode foil 5, a cathode foil 6, an electrolytic paper 7 located between the anode foil 5 and the cathode foil 6, a positive electrode lead 3 and a negative electrode lead 4, and the electrolytic paper 7. Impregnated with monomers and oxidants, and the monomers and oxidants generate conductive polymers on the electrolytic paper. The monomer is one of EDOT (3,4-ethylenedioxythiophene) and its derivatives, pyrrole, and aniline or more, the oxidant is one or more of ferric p-toluenesulfonate, ammonium persulfate, sodium persulfate, ammonium sulfate, and ferric chloride; the positive electrode lead 3 and the negative electrode lead 4 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com