motor with armature

A technology of armature and armature shaft, which is applied in the manufacture of motor generators, electromechanical devices, electrical components, etc., to achieve the effect of saving parts and flexible process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

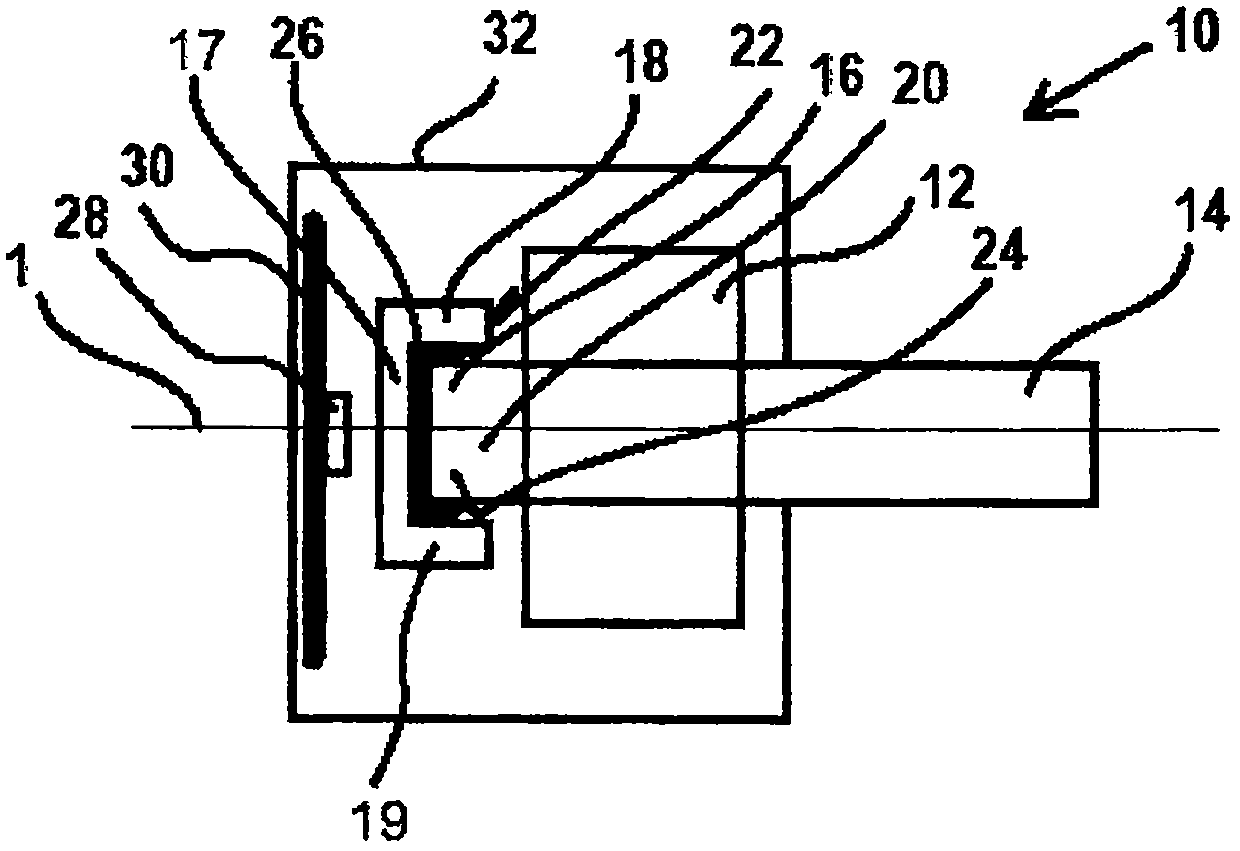

[0017] figure 1 The motor 10 is shown in . The electric machine 10 has a housing 32 . The armature 12 is arranged within the housing 32 . An armature shaft 14 is arranged along the axis of rotation 1 of the armature 12 . The armature shaft 14 protrudes from the housing 32 . Furthermore, the armature shaft 14 protrudes on both sides of the armature 12 . In this case the axial end 16 of the armature shaft 14 terminates inside the housing 32 .

[0018] A sensor magnet 18 is arranged on the axial end 16 . The sensor magnet 18 has a recess 20 on its axial side 22 facing the armature 12 . The recess 20 is realized as a blind hole. It is however conceivable that the bottom 17 of the blind hole is perforated with at least one hole. In this case the hole can have various shapes. The holes can be designed as deep holes. It is also conceivable that the wall 19 of the cylindrical sensor magnet is likewise cut or punched with a recess 20 . A wall 19 of a pot-shaped, cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com