Thermoplastic rubber composition and molded product using same

A thermoplastic rubber and composition technology, which is applied in the field of thermoplastic rubber compositions, can solve problems such as difficult hardness control, and achieve the effect of easy hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4 and comparative example 1-6

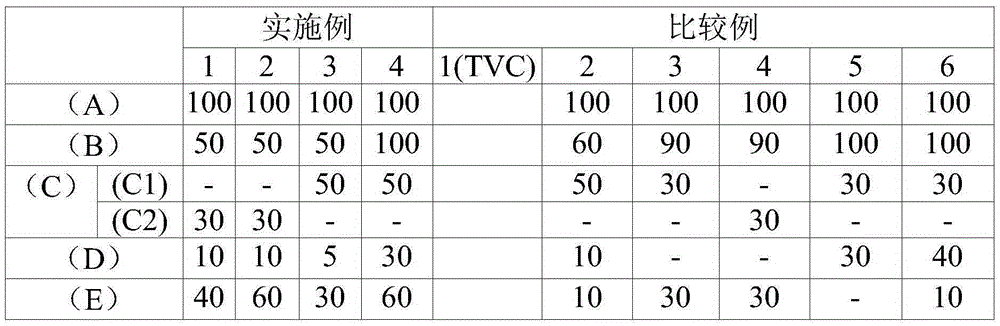

[0101] Various ingredients were mixed in a general mixer according to the composition (unit: parts by weight) summarized in Table 1 below.

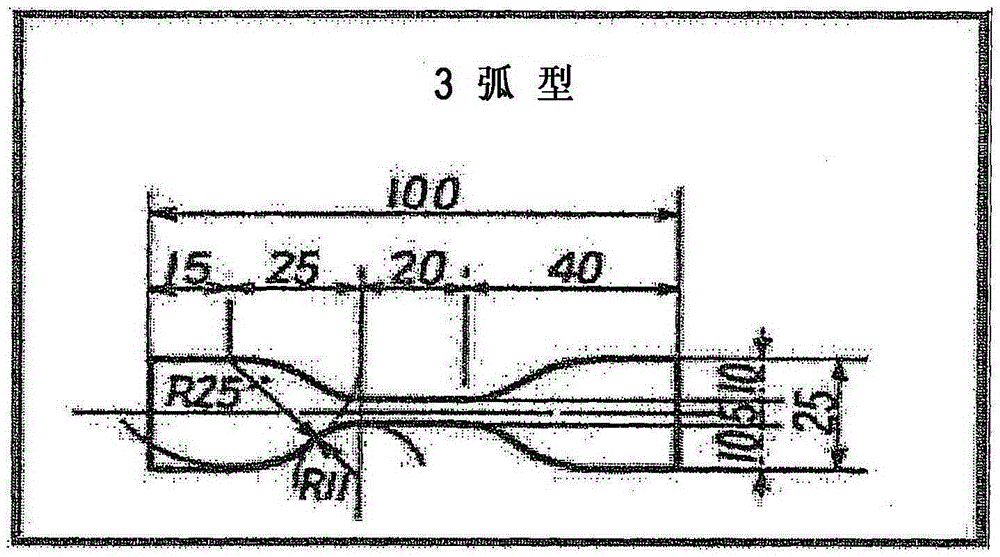

[0102] The mixed thermoplastic rubber composition was stirred at a rate of 600 rpm at 40° C. for 10 minutes in a Henschel mixer, and then used a twin-screw extruder to form a pellet phase, wherein L / D=36 and Φ=45 mm, and An underwater cutter was used at a fixed temperature of 250°C and a screw speed of 300 rpm. The prepared particles were dried at 80°C for 2 hours. Subsequently, a PC sample previously prepared in a 10-ton injection molding machine in the first loop direction was installed in a mold, and a sample for performance measurement was produced by injection molding at an injection temperature of 200°C. Next, the properties of the samples were determined and the results are summarized in Table 1 below.

[0103] Table 1

[0104] [Table 1]

[0105]

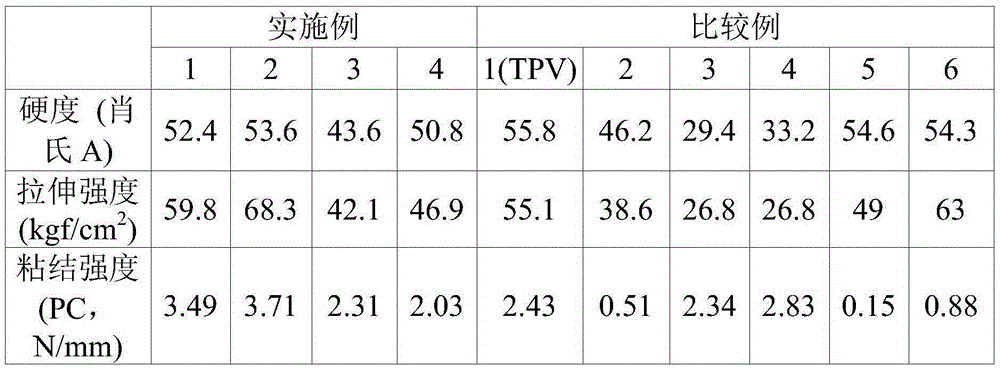

[0106] The properties of the prepared samples were determined according to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com