Method for controllably preparing MPP trenchless pipe surface coating by using diamond powder

A surface coating, diamond powder technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve problems such as scratches, pipe damage, damage to polymer crystalline state, etc., to achieve controllable hardness, safe and environmentally friendly manufacturing process, Uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

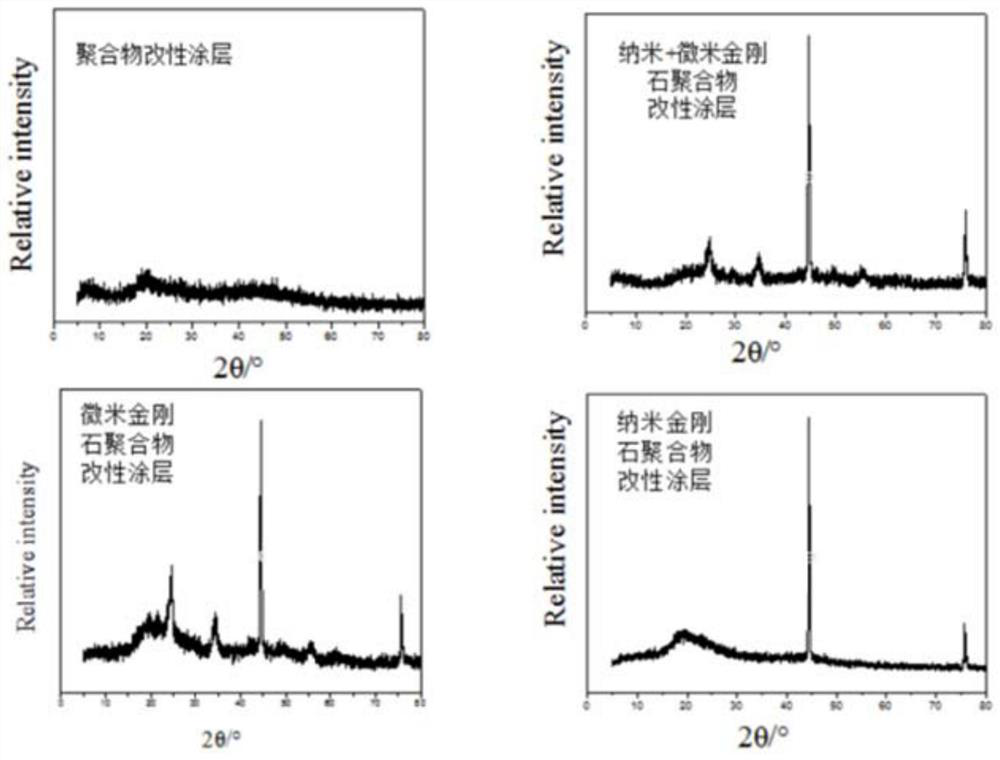

[0031] Surface coating of MPP trenchless pipe modified by micron and nanometer diamond powder

[0032] Proceed as follows:

[0033] ① First wash the reaction tube twice with ethanol / water solution, weigh 1 g of nano-diamond powder (particle size 80-100 nm) and place it in the reaction tube, then add 0.1 g of aminopropyltriethoxysilane, 1 g of ethanol, and 0.2 g of water g. 2 g of hyperbranched polyester, kept in a water bath at 50° C. for 10 minutes. At 4000rpm, emulsify and homogeneously stir with high-speed shearing 4 times, 2min each time. After the reaction was complete, 1 g of deionized water was added, and the ethanol was removed by rotary evaporation at 80° C. to obtain a mixed solution of modified nano-diamond powder dispersed in hyperbranched polyester.

[0034] ② Wash the reaction tube twice with ethanol / water solution, weigh 0.5g of micron diamond powder (particle size: 5-25μm) and place it in the reaction tube, then add 0.05g of aminopropyltriethoxysilane, 1g of ...

Embodiment 2

[0038] Micron Diamond Powder Modified MPP Trenchless Pipe Surface Coating

[0039] The steps are the same as in Example 1, step 1 is omitted, and the mass ratio of the mixed liquid in which the modified micron diamond powder is dispersed in hyperbranched polyester to the water-based polyisocyanate in step 3 is adjusted to be 1.5:0.75.

Embodiment 3

[0041] Nano-diamond Powder Modified MPP Trenchless Pipe Surface Coating

[0042] The steps are the same as in Example 1, step 2 is omitted, and the mass ratio of the mixed liquid in which the modified nano-diamond powder is dispersed in the hyperbranched polyester to the water-based polyisocyanate in step 3 is adjusted to be 1.5:0.75.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com