Pearlite rail having superior abrasion resistance and excellent toughness

A technology for pearlite and steel rails, applied in the field of pearlite system steel rails, can solve the problems of unevenness, inability to stably improve the damage resistance and toughness of steel rails, and coarse grains, so as to increase service life, improve wear resistance and toughness , the effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0169] Next, examples of the present invention will be described.

[0170] Tables 1 to 6 show the chemical components of the test rail steels. In addition, the remainder contains Fe and unavoidable impurities. Rail steels having the compositions shown in Tables 1 to 6 were manufactured by the following method.

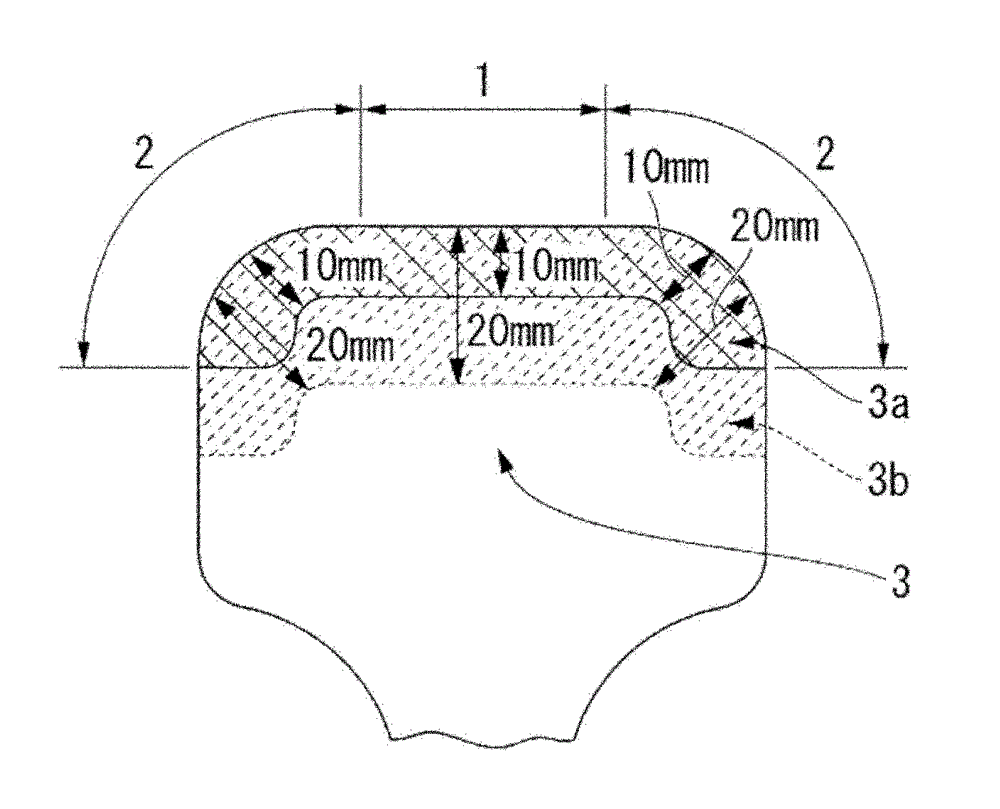

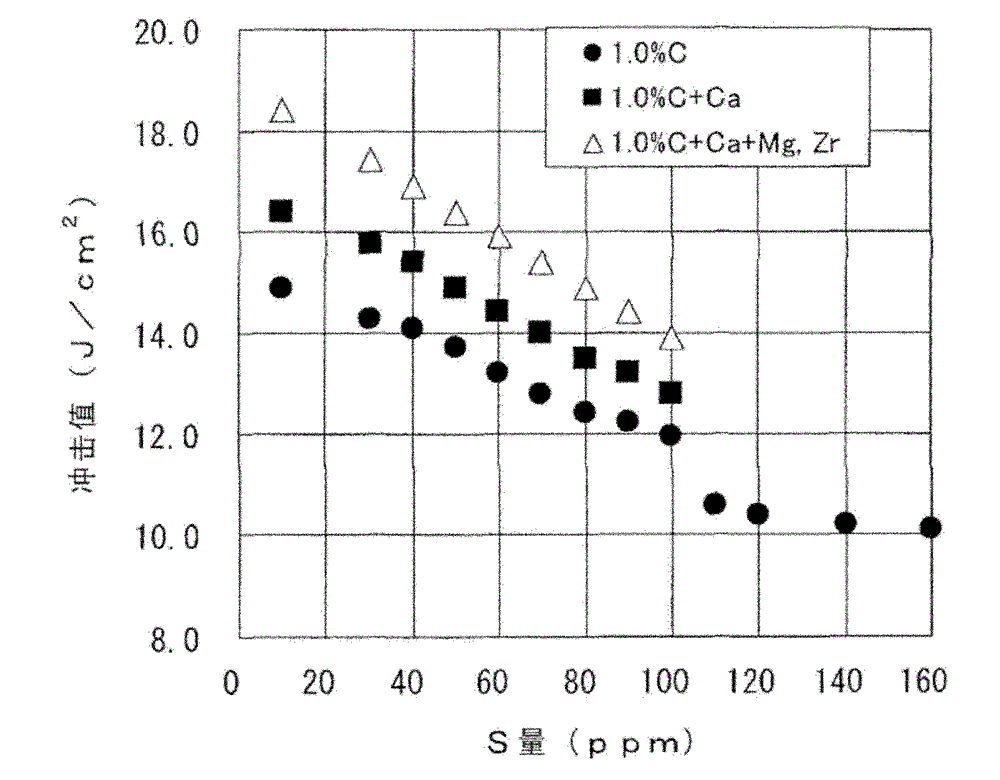

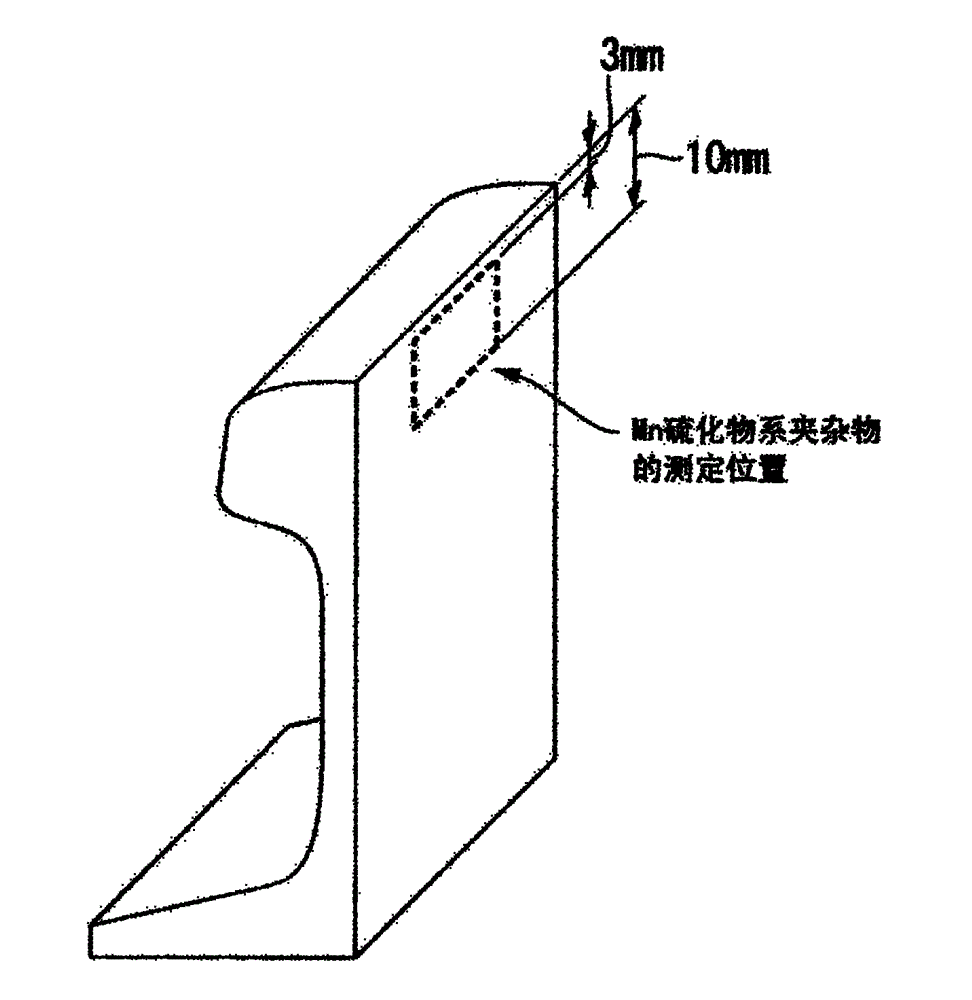

[0171] Dephosphorization and desulfurization are carried out in the molten iron stage, and sufficient dephosphorization and desulfurization are performed in commonly used melting furnaces such as converters and electric furnaces to obtain molten steel. By adding Ca to the molten steel, Mn sulfide-based inclusions are controlled, or by adding Mg and Zr separately, nano-sized oxides and Mn sulfide-based inclusions are finely dispersed. Then, a steel ingot is produced by a continuous casting method, and the steel ingot is hot-rolled. Then, a rail is produced by applying heat treatment.

[0172]

[0173]

[0174]

[0175]

[0176]

[0177]

[0178] (a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com