Blast furnace overhaul method

A technology for blast furnaces and new furnaces, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems of not being directly applicable to blast furnaces, economic losses, shortening construction periods, etc., and achieve the effects of shortening the overhaul period, high-precision handling, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

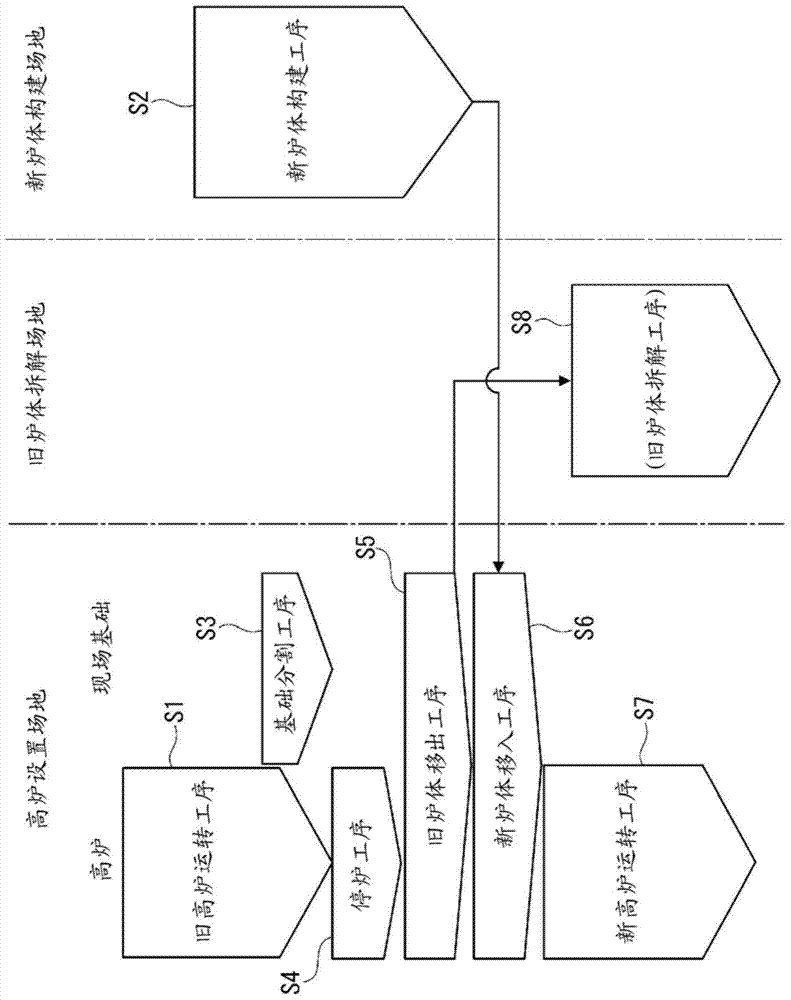

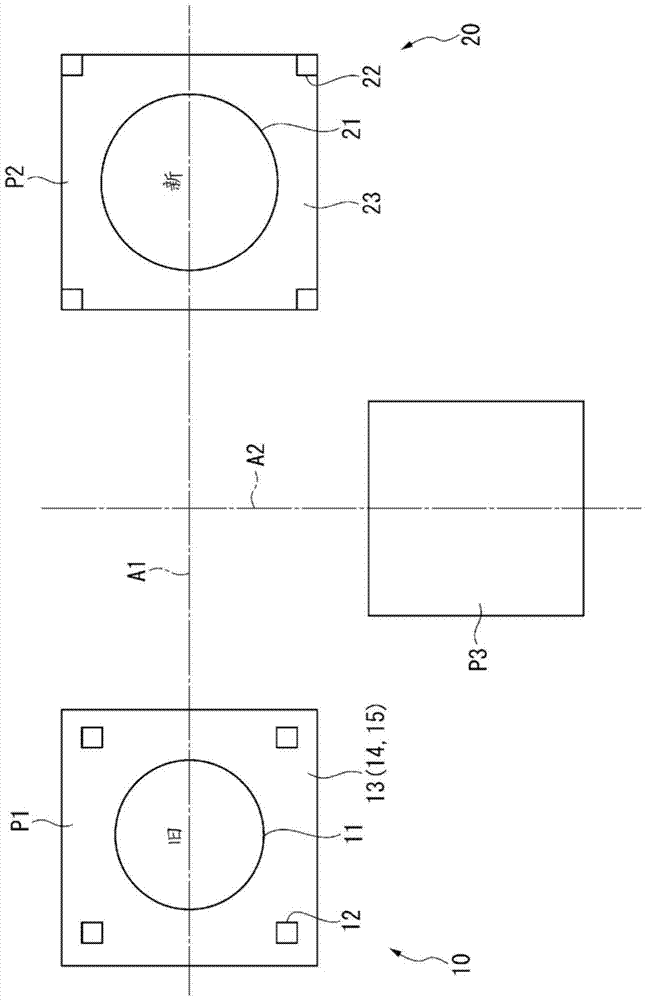

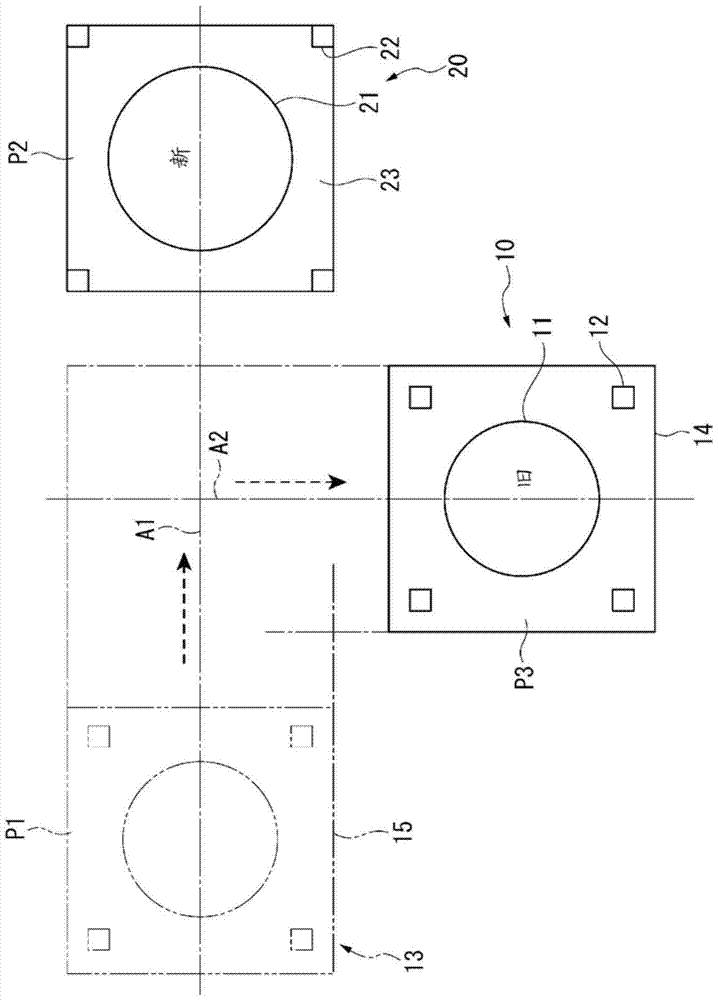

[0110] Figure 1 ~ Figure 4 Each of the figures in the figure shows the outline of the blast furnace overhaul process implemented in this embodiment ( figure 1 ), the plane configuration of the operating site used for overhaul ( figure 2 ), the removal process of the old furnace body ( image 3 ) and the new furnace body into the process ( Figure 4 ).

[0111] exist figure 2 Among them, the blast furnace (old blast furnace 10) to be overhauled in this embodiment is installed on the blast furnace installation site P1. In the blast furnace installation site P1, the old furnace body 11 and the old furnace body tower 12 are built on the site foundation 13 . The plane of the site foundation 13 is rectangular, and a new furnace body construction site P2 is set on the axis A1 perpendicular to the midpoint of one side of the plane shape of the site foundation 13 .

[0112] On the new body of furnace construction site P2, carry out the new body of furnace construction process ...

no. 2 Embodiment approach

[0253] Figure 25 and Figure 26 The second embodiment of the present invention is shown.

[0254] Similar to the above-mentioned first embodiment, this embodiment also follows Figure 1 ~ Figure 4 The general procedure shown is for a blast furnace overhaul. However, what differs from the above-mentioned first embodiment is the structure of the conveyance device 30A for removal used in the old furnace body removal process S5. Therefore, in the following description, repeated descriptions of the same matters will be omitted, and only different parts will be described.

[0255] In the above-mentioned first embodiment, the transport device 30 for removal (refer to Figure 8 ) in order to carry out the third transport operation (transport along the axis A2 direction towards the old furnace body dismantling site P3), and use the recess 33 arranged on the ground, the sliding structure part 43 arranged on the bottom surface of the recess 33 and the The fork moving stage 32 that ...

no. 3 Embodiment approach

[0265] Figure 27 ~ Figure 30 Each figure of FIG. 3 shows the 3rd embodiment of this invention.

[0266] Similar to the above-mentioned first embodiment, this embodiment also follows Figure 1 ~ Figure 4 The general procedure shown is for a blast furnace overhaul. However, the difference from the above-mentioned first embodiment is the configuration of the transfer device 30B used in the old furnace body removal step S5 and the configuration of the transfer device 39B used in the new furnace body transfer step S6. Therefore, in the following description, repeated descriptions of the same matters will be omitted, and only different parts will be described.

[0267] First, the conveyance apparatus 30B for removal used in the old furnace body removal process S5 is demonstrated.

[0268] In the above-mentioned first embodiment, the transport device 30 for removal (refer to Figure 8 ) for the first to third conveying operations has: a sliding structure part 41 (height L1) arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com