Method for processing fresh keeping filling at superhigh pressure

An ultra-high pressure and filling technology, applied in the field of food processing, can solve the problems of inability to guide, insufficient research on the mechanism of ultra-high pressure, and imperfect technical parameters and data of ultra-high pressure treatment, so as to achieve the effect of preventing mold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

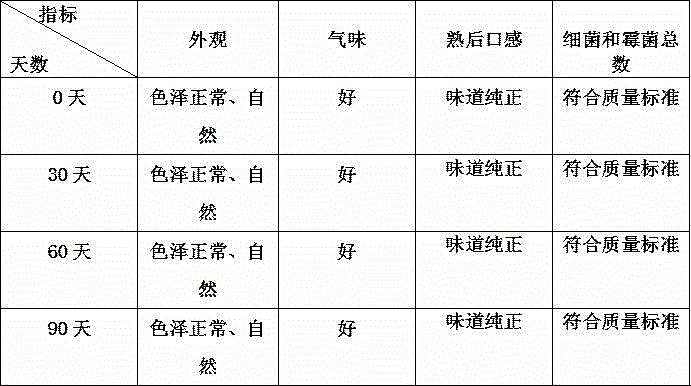

Image

Examples

Embodiment 1

[0022] A method for ultra-high pressure processing fresh-keeping fillings, comprising the steps of:

[0023] (1) Put the prepared cabbage and pork stuffing into a sealed bag, and vacuum seal;

[0024] (2) Put the vacuum-packed stuffing into the liquid pressure medium in the ultra-high pressure container;

[0025] (3) At room temperature, the vacuum-packed stuffing is subjected to ultra-high pressure treatment, the temperature is room temperature, the pressure is 400Mpa, the pressure holding time is 20 minutes, the pressure is maintained twice, and the pressure is released.

Embodiment 2

[0027] A method for ultra-high pressure processing fresh-keeping fillings, comprising the steps of:

[0028] (1) Put the prepared mutton stuffing into a sealed bag and vacuum seal it;

[0029] (2) Put the vacuum-packed stuffing into the liquid pressure medium in the ultra-high pressure container;

[0030] (3) At room temperature, the vacuum-packed stuffing is subjected to ultra-high pressure treatment, the temperature is room temperature, the pressure is 350Mpa, the pressure holding time is 20 minutes, the pressure is maintained 3 times, and the pressure is released.

Embodiment 3

[0032] A method for ultra-high pressure processing fresh-keeping fillings, comprising the steps of:

[0033] (1) Put the prepared fish stuffing into a sealed bag and vacuum seal;

[0034] (2) Put the vacuum-packed stuffing into the liquid pressure medium in the ultra-high pressure container;

[0035] (3) At room temperature, the vacuum-packed stuffing is subjected to ultra-high pressure treatment, the temperature is room temperature, the pressure is 500Mpa, the pressure holding time is 15 minutes, the pressure is maintained twice, and the pressure is released.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com