A bonding and sorting machine for flat sheet parts

A technology for sorting machines and parts, which is applied in the field of sorting machines to achieve the effects of good vibration effect, labor cost saving and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

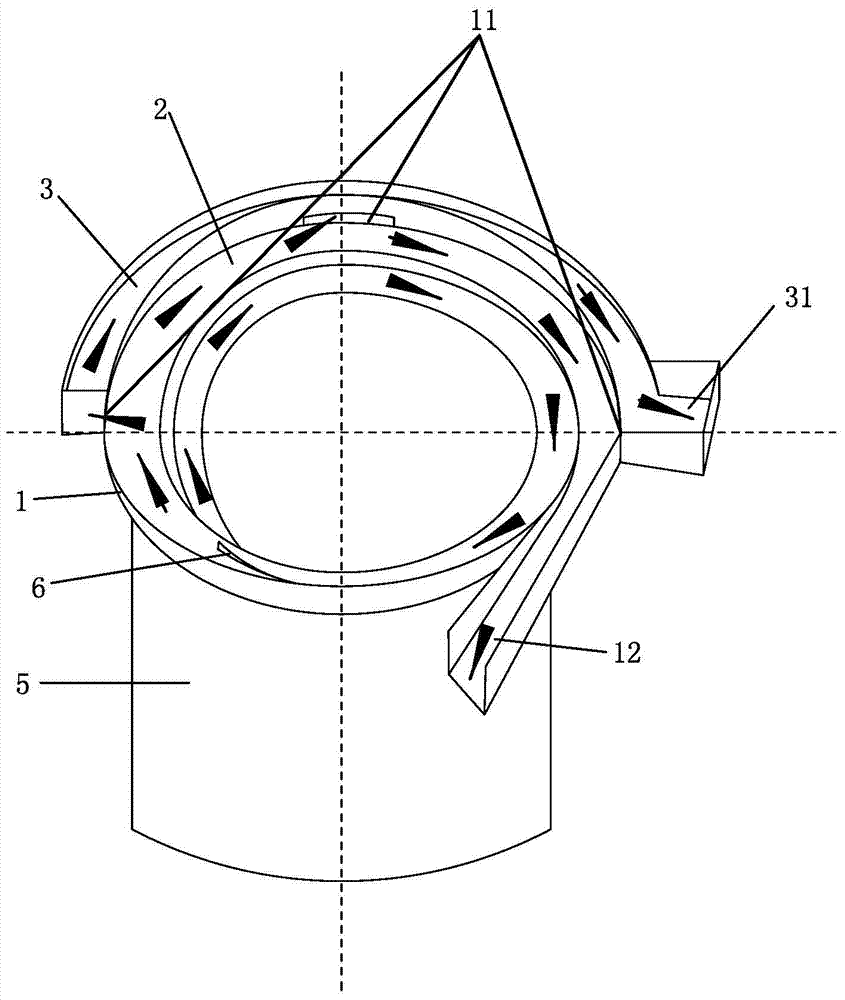

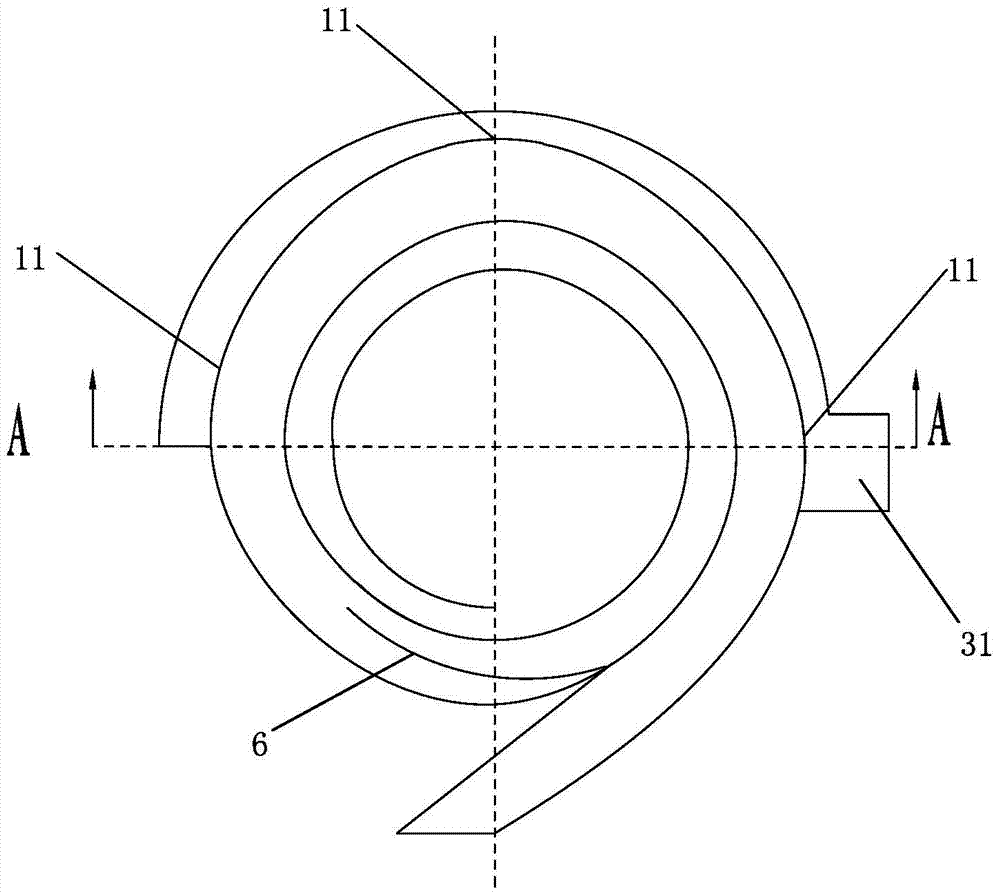

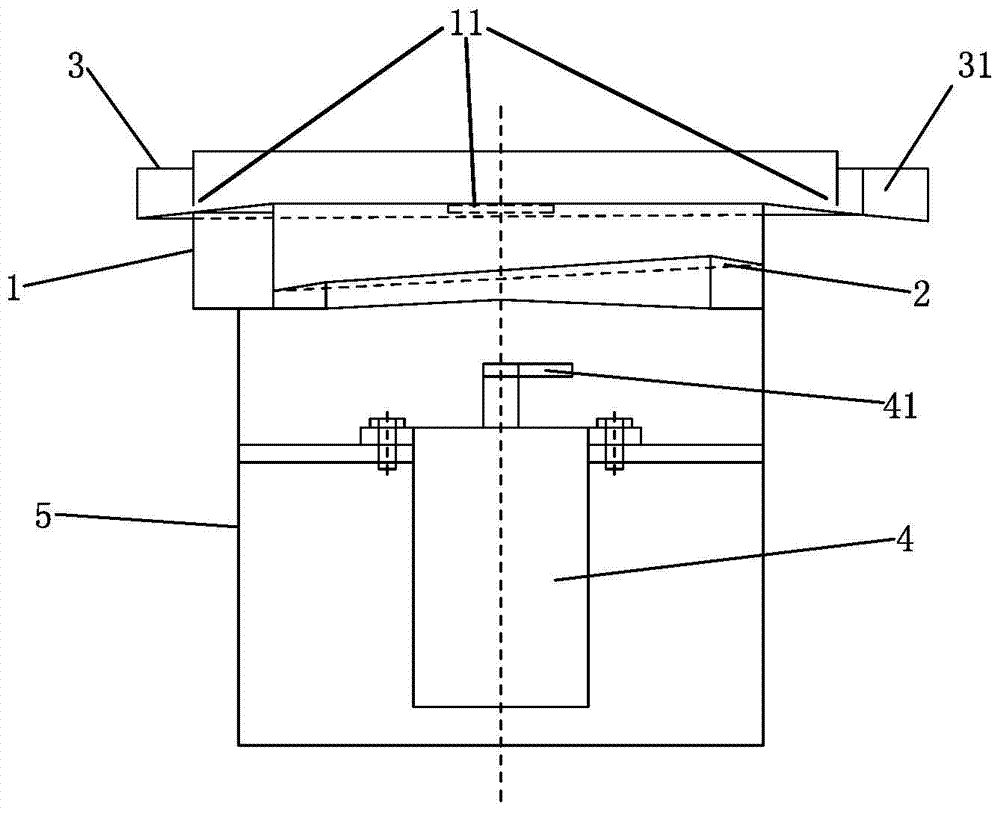

[0027] Examples, see Figure 1-Figure 3 As shown, a kind of flat sheet parts bonding sorting machine of the present invention comprises: a spiral hopper 1, and the spiral hopper 1 is provided with a spiral feedway 2 that spirals upward along the side walls around it, and the spiral hopper 1 is also provided with There is a first discharge port 11 that only allows qualified parts to be discharged and a second discharge port 12 for bonded parts to be discharged. The first discharge port 11 is located on the side wall of the screw hopper 1 and communicates with the screw channel 2; a vibration The mechanism is used to drive the screw hopper 1 to vibrate, so that the parts placed in the screw hopper 1 move along the screw hopper 2 . The vibration mechanism specifically includes a vibration motor 4, and also includes a mounting body 5, the mounting body 5 is specifically a hollow cylinder, the vibration motor 4 is installed in the mounting body 5, and the screw hopper 1 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com