Cleaning tank for automobile parts

A technology for auto parts and cleaning pools, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems that non-ferrous metals and non-metallic products are not suitable for use, prone to fatigue, and incomplete cleaning, etc. , to achieve the effect of easy operation, good stability and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

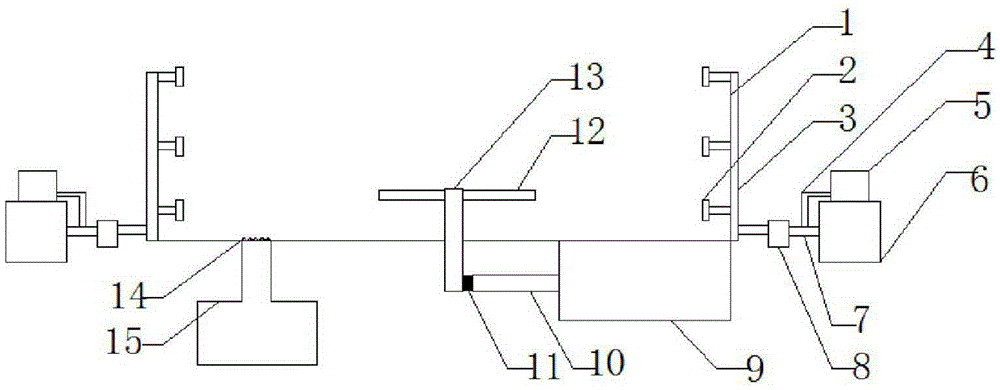

[0018] Specific implementation method: when in use, it is necessary to check whether the shower head 2 can work normally, whether the stirring rod 12 is damaged, if there is a defect in the inspection, it will not work, and if everything is normal, it can work. When cleaning parts, It is necessary to distinguish whether chemical cleaning is required. If chemical cleaning is required, the required chemical cleaning agent needs to be added to the chemical reagent chamber 5, and the parts to be cleaned are placed at the bottom of the pool body 1. The chemical cleaning agent in the chemical reagent chamber 5 Enter the water pipe 7 through the adding pipe 4, the chemical cleaning agent mixes with the water in the water tank 6, enters the spray pipe 3 through the action of the booster pump 8, and finally sprays out from the spray head 2, turns on the driving motor 9, and the driving motor 9 drives the rotation The rod 10 rotates, and the rotating rod 10 drives the connecting rod 13 t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap