Fast locating instrument for numerical control machining original point and positioning method of numerical control machining original point

A locator, origin technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problem of time-consuming and other problems, achieve the effect of convenient operation, accurate measurement and positioning methods, and improve positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

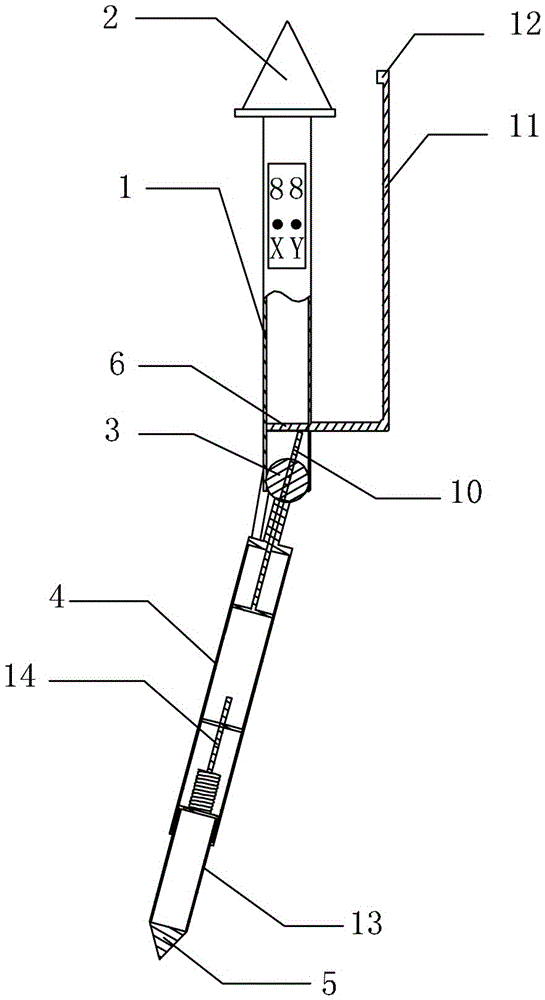

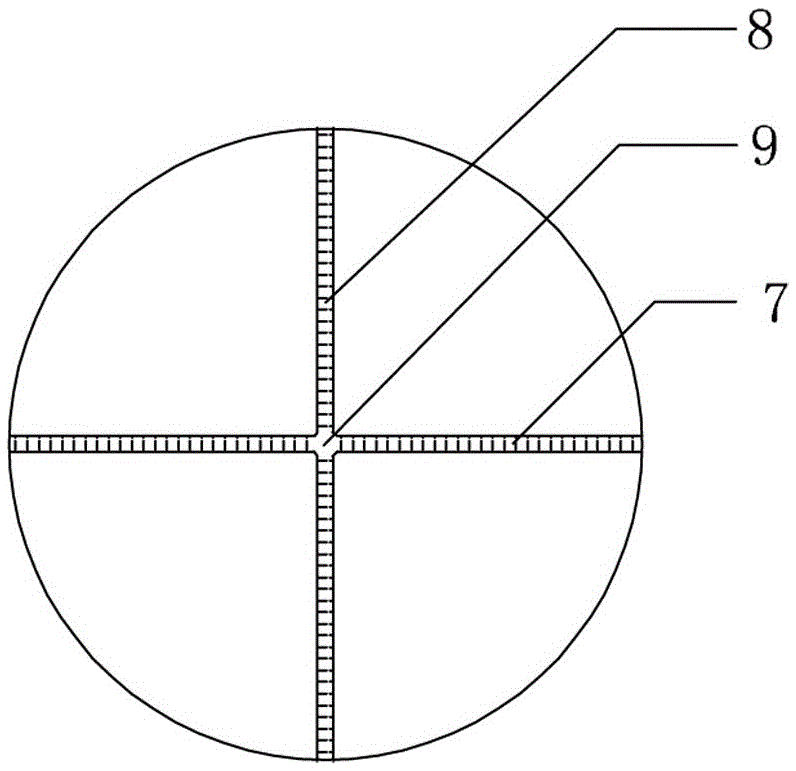

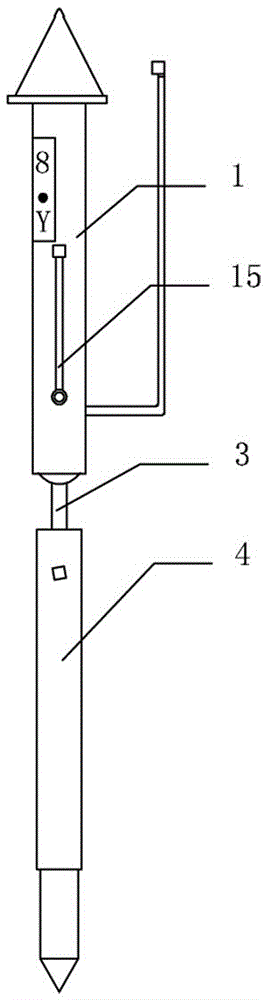

[0023] like figure 1 As shown in the figure, a fast locating instrument for CNC machining origin is provided with an upper cone seat 2 on the upper end of the fixed rod 1, and the upper end cone seat 2 is used to be installed in the tool taper hole of the spindle, and the lower end of the fixed rod passes through the universal connector 3 Connect the movable movable rod 4, the bottom of the movable rod is provided with the lower end cone seat 5; the conductive disc 6 arranged horizontally is arranged in the cavity of the fixed rod 1, and the bottom surface of the conductive disc 6 is provided with the X-axis conductor 7 and the Y-axis conductor 8. The X-axis conductor 7 and the Y-axis conductor 8 are perpendicular, and the intersection point is set as the origin 9, and the origin is located on the vertical axis of the upper cone seat 2; a conductive probe 10 is provided in the movable rod 4, and the upper end of the conductive probe 10 is Pass through the universal connector 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com