Bar material mechanical carrying device

一种搬运装置、棒料的技术,应用在机械手、卷扬装置、运输和包装等方向,能够解决夹持不牢、生产效率低、能力差等问题,达到避免环境温度高、夹持棒料稳定、机械结构简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

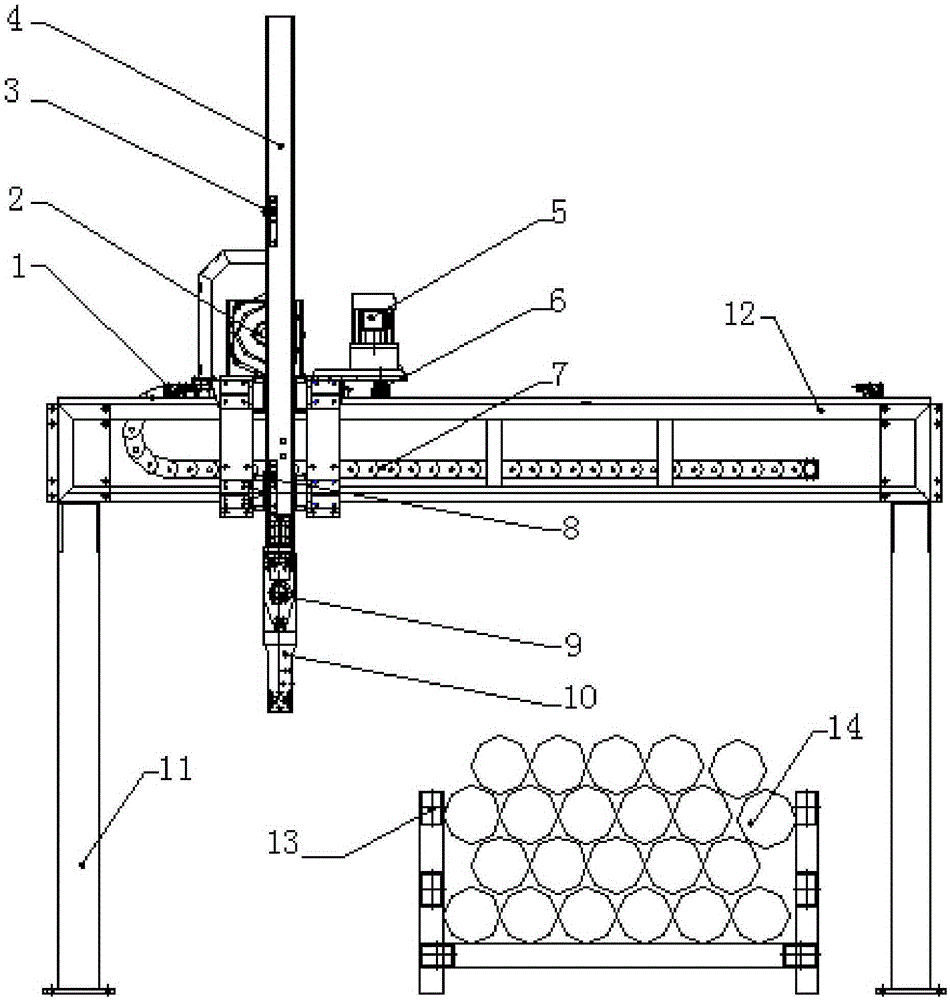

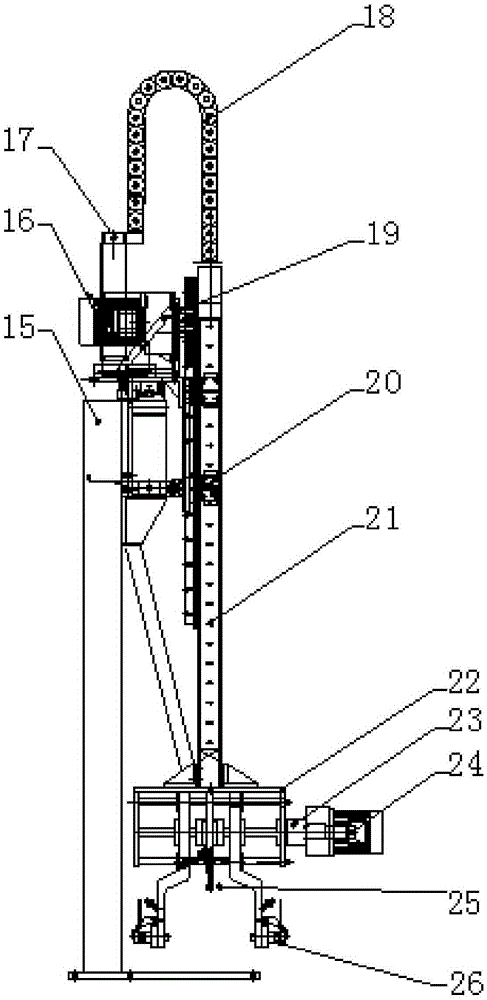

[0017] The bar material handling mechanical device is mainly composed of a frame connection part, a vertical movement part, a horizontal movement part, a mechanical gripper part and a man-machine exchange display part, and consists of three mutually perpendicular lead screws, a rack and a mechanical claw at the bottom; Fully automatic calculation of the grasping position and travel speed of various bars of 8 inches, 9 inches and 10 inches, and real-time detection of the gripping torque without the participation of the operator. The mechanical structure is simple, the gripping bar is stable, and it is convenient to use.

[0018] The bar material handling mechanical device obtains the diameter of the bar material according to the exchange communication of the upper computer, determines the positioning data of the first bar material, calculates the difference between the odd-numbered layer and the even-numbered layer of the bar material stacked, and the relative positioning address...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com