A buffer system with a visual window for a silane cross-linked cable material production line

A silane cross-linking and buffer system technology, applied in the field of buffer tanks, can solve the problems that waste dust and gas cannot be processed in time, products cannot meet the processing requirements, and affect the quality of production products, etc., to improve operating efficiency, simple structure, and convenient observation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

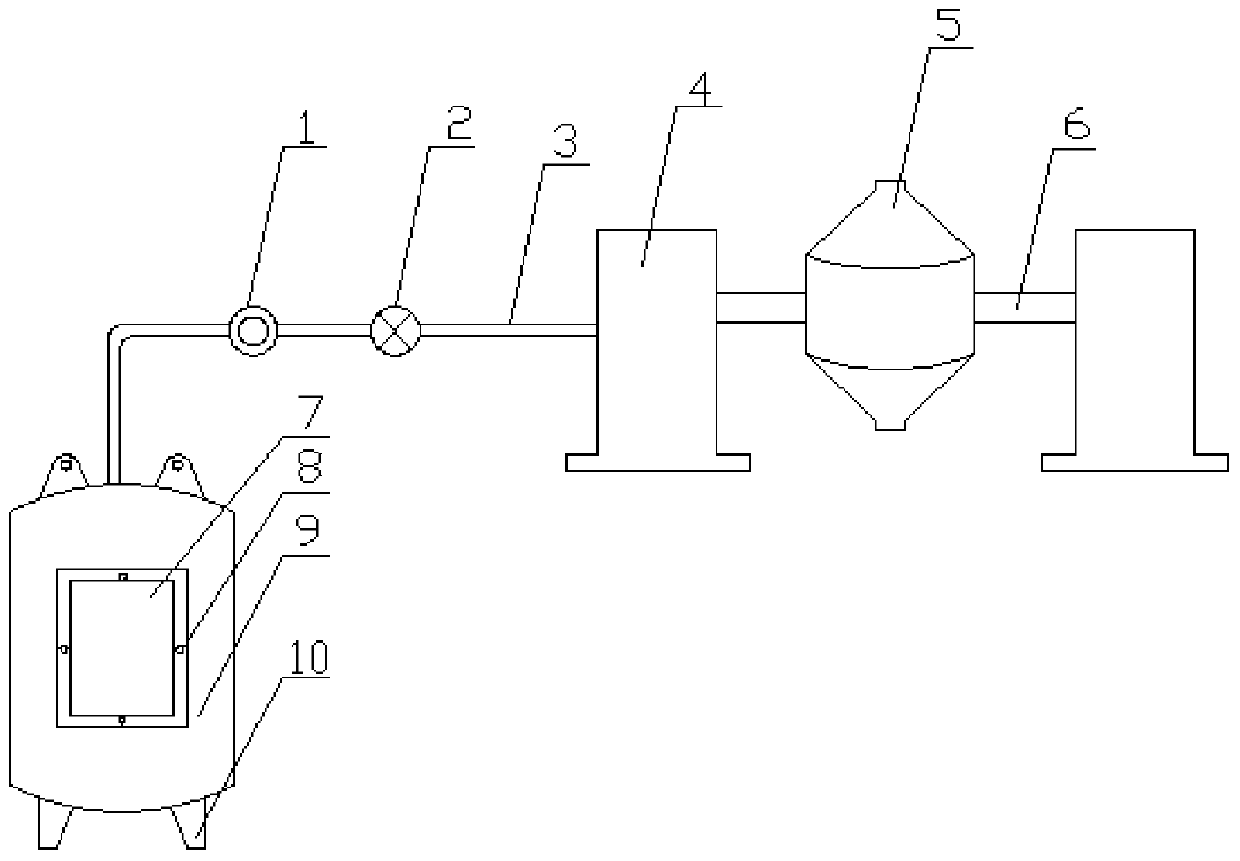

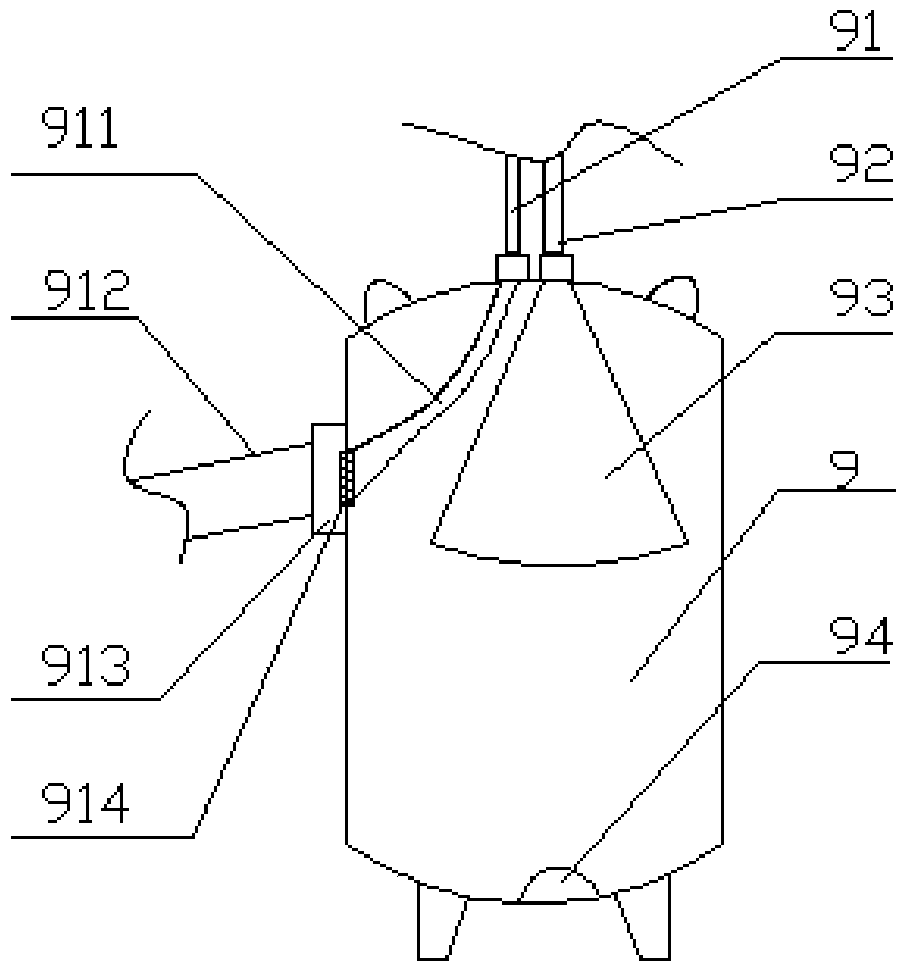

[0028] A buffer system with a viewing window for a silane cross-linked cable material production line, which includes, from left to right, a buffer tank 9, a pipeline 3, a solenoid valve 1, a pneumatic pump 2, and a mixer 5, and the mixer 5 passes through the pipeline 3 is connected to the buffer tank 9, the pipeline 3 includes a waste gas delivery pipe 91 and a dust delivery pipe 92, the waste gas output pipe 91 is connected to the waste gas conduit 911 set in the buffer tank 9, and the waste gas conduit 911 is connected to the The condenser 913 on the outer surface of the buffer tank 3 is connected, the condenser 913 is connected with a liquefied waste liquid outlet 912, the dust conveying conduit 92 is connected with the collection cover 93 provided in the buffer tank 9, and the outer wall of the buffer tank 9 is provided with a The window 7, the bottom of the buffer tank 9 is provided with two bases 10.

[0029] The exhaust gas conveying pipe 91 and the dust conveying pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com