Microwave automatic heating device and method

An automatic heating and microwave technology, applied in the microwave field, can solve the problems of uncontrolled heating and curing, slow heat dissipation in the center of the part, slow center heating, etc., and achieve the effect of shortening heating time, small thermal inertia, and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

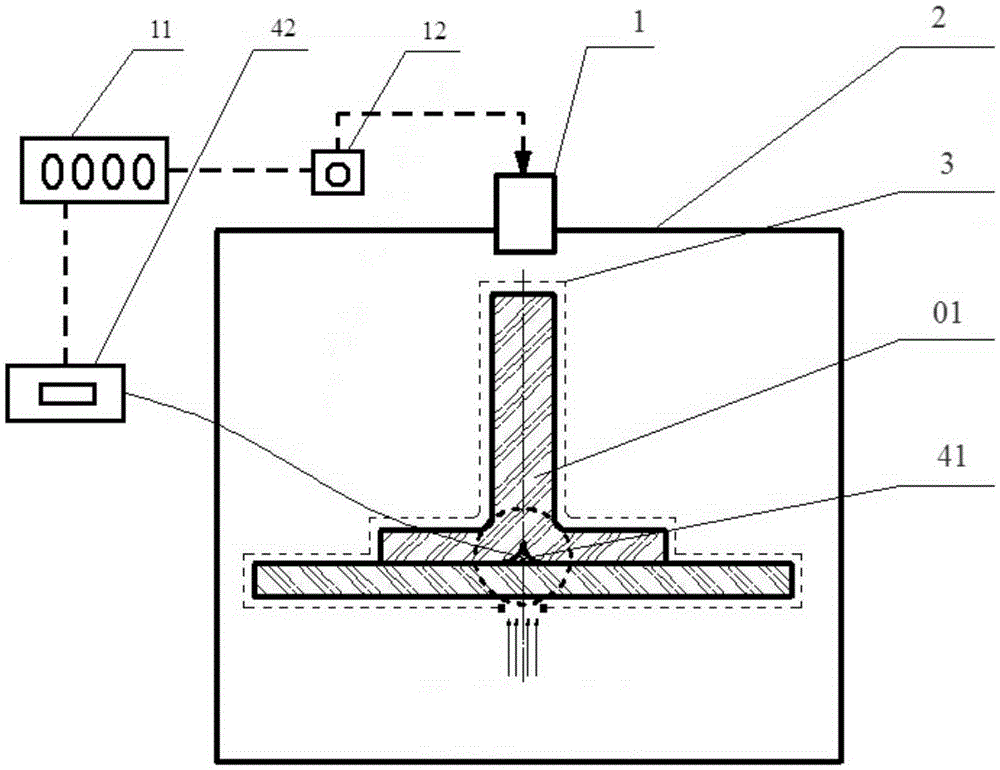

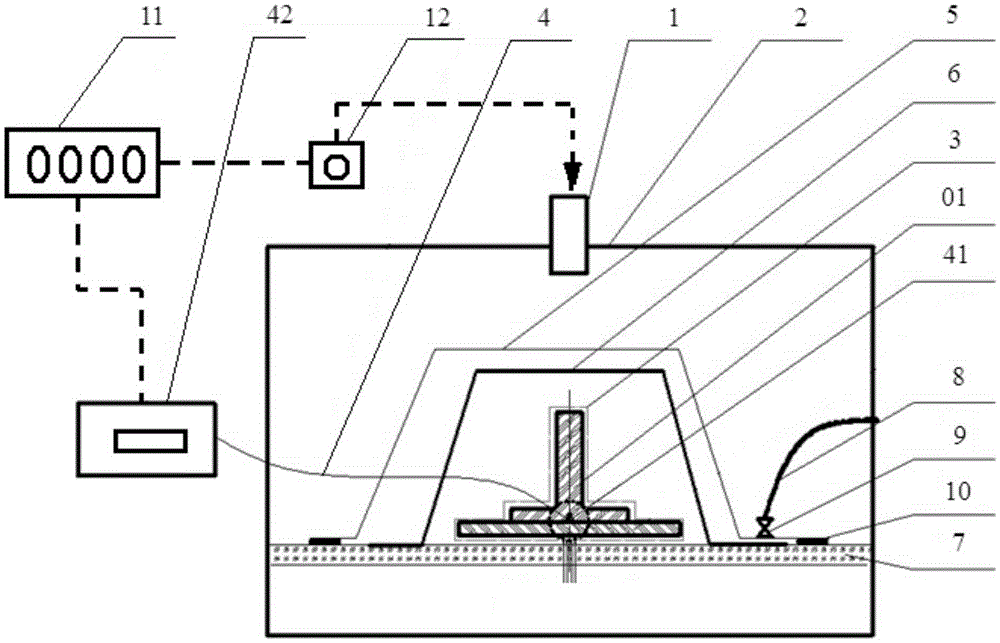

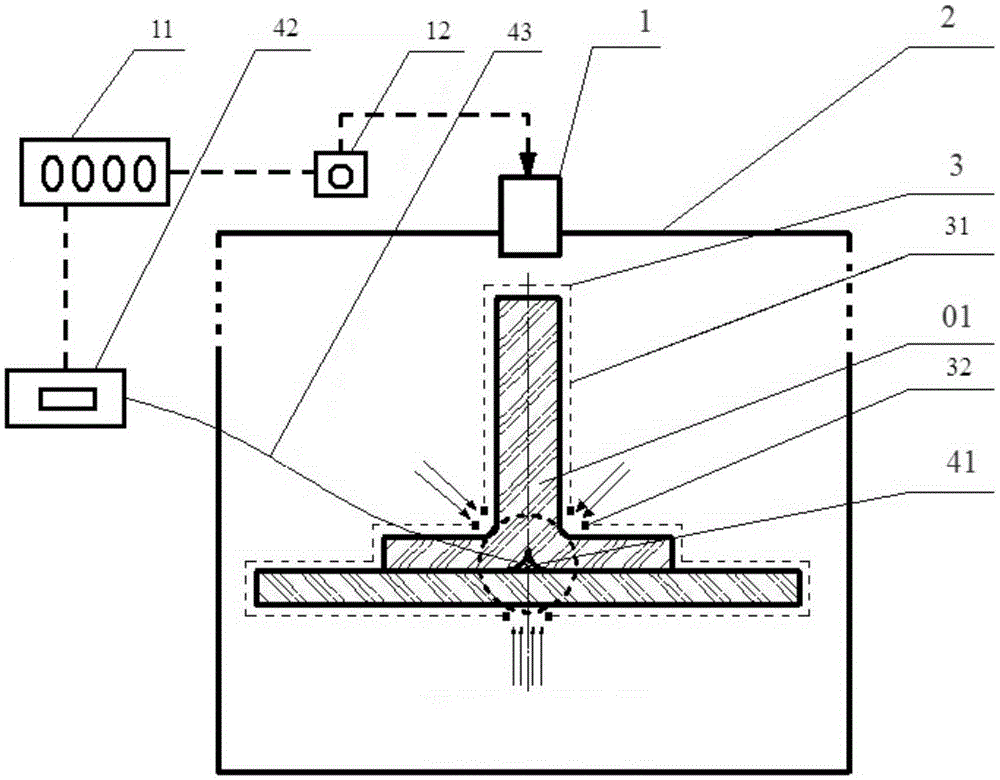

[0032] figure 1 A microwave automatic heating device is provided, including a microwave generator 1, a microwave cavity 2, a microwave partial shield 3, a control system 11, a microwave power control module 12 and a temperature measuring device 4, and the microwave generator sends Microwave, the microwave cavity is used to place the microwave absorbing material 01, the microwave partial shield is located in the microwave cavity and is used to cover the outer surface of the microwave absorbing material, the microwave partial shield consists of shielding the microwave area and transmitting the microwave area Composition, the microwave transmission zone includes one or more slits so that the microwave energy in the microwave cavity enters the absorbing material from the slit and is absorbed by it; the temperature measuring device includes a temperature measuring head 41, a data acquisition instrument 42 and A temperature measurement transmission line 43, the temperature measureme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com