A constant-angle printing method and device for grid lines of solar cells

A technology of solar cells and printing methods, which is applied to printing devices, printing machines, printing machines, etc., can solve the problems of increasing the probability of cell sticking under the screen, the loss of production capacity during shutdown, and the scrapping of cells, etc., and achieves simple structure, Easy to operate and achieve simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

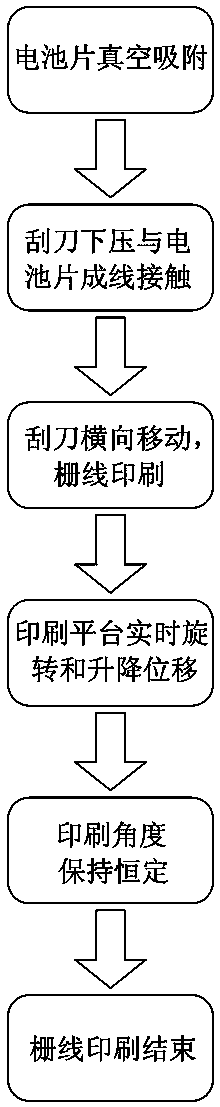

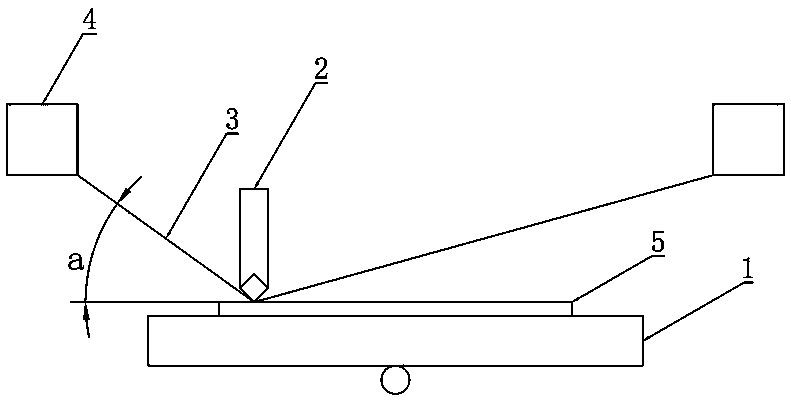

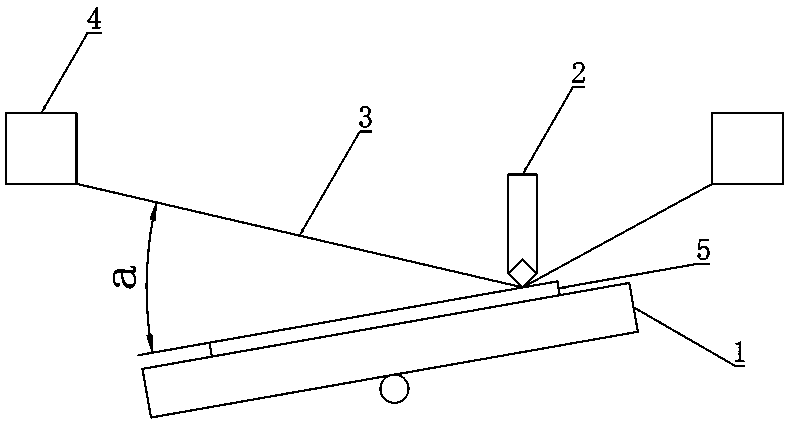

[0026] Such as figure 1 As shown, in the solar cell grid constant angle printing method of this embodiment, when the printing blade 2 acts on the screen 3 to print grid lines to the solar cell 5, the position of the printing platform 1 carrying the solar cell 5 is adjusted in real time so that the screen The angle α between 3 and printing platform 1 is constant. The solar cell grid line constant angle printing method of the present invention ensures that the angle between the printing platform 1 and the screen 3 is constant by adjusting the position of the printing platform 1, thereby ensuring that the printing blade 2 acts on the screen 3 to print on the solar cell 5 The paste is relatively uniform, that is, the height and width of the printing paste are highly consistent, thereby greatly improving the printing quality and ensuring the qualit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com