A grinding machine for petroleum machinery gear parts

A technology of grinding processing and petroleum machinery, which is applied in the direction of grinding frame, grinding workpiece support, grinding machine tool parts, etc., which can solve the problems of reduced precision, easy damage, and difficulty in ensuring the precise fit of grinding knives. Achieve the effect of ensuring accuracy, avoiding offset, and ensuring stable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

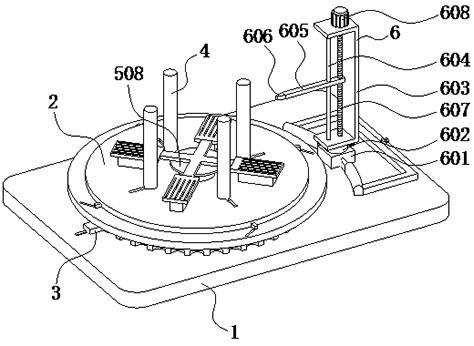

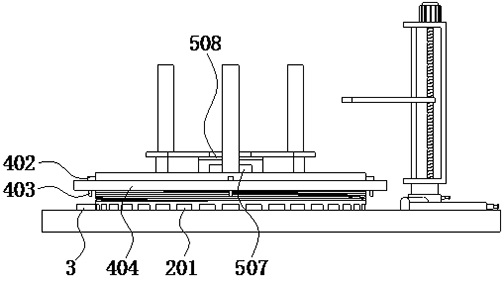

[0030] Such as figure 1 with image 3 As shown, the present embodiment provides a grinding machine for petroleum machinery gear parts, including a horizontal base plate 1, a vertical rotating column 2 is installed on the upper surface of the base plate 1, and the circumferential surface of the rotating column 2 is uniform along its circumferential direction. A plurality of positioning holes 201 are opened, and a positioning block 3 cooperating with the positioning holes 201 is slidably installed on the upper surface of the bottom plate 1 .

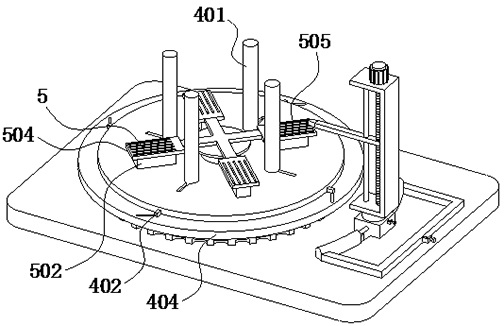

[0031] Such as figure 2 with image 3 As shown, the inner support mechanism 4 is installed on the rotating column 2, and the inner supporting mechanism 4 includes several inner support rods 401 uniformly ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com