Filling equipment for avoiding volatilization and pollution of filled liquid

A filling equipment and liquid technology, applied in the field of mechanical equipment, can solve the problems that the support structure of the foot cup is not enough to provide a stable support, affect the stability of the filling barrel, and the filling barrel is dumped, etc., to solve the problem of volatile gas pollution, rotation Smooth, environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific drawings.

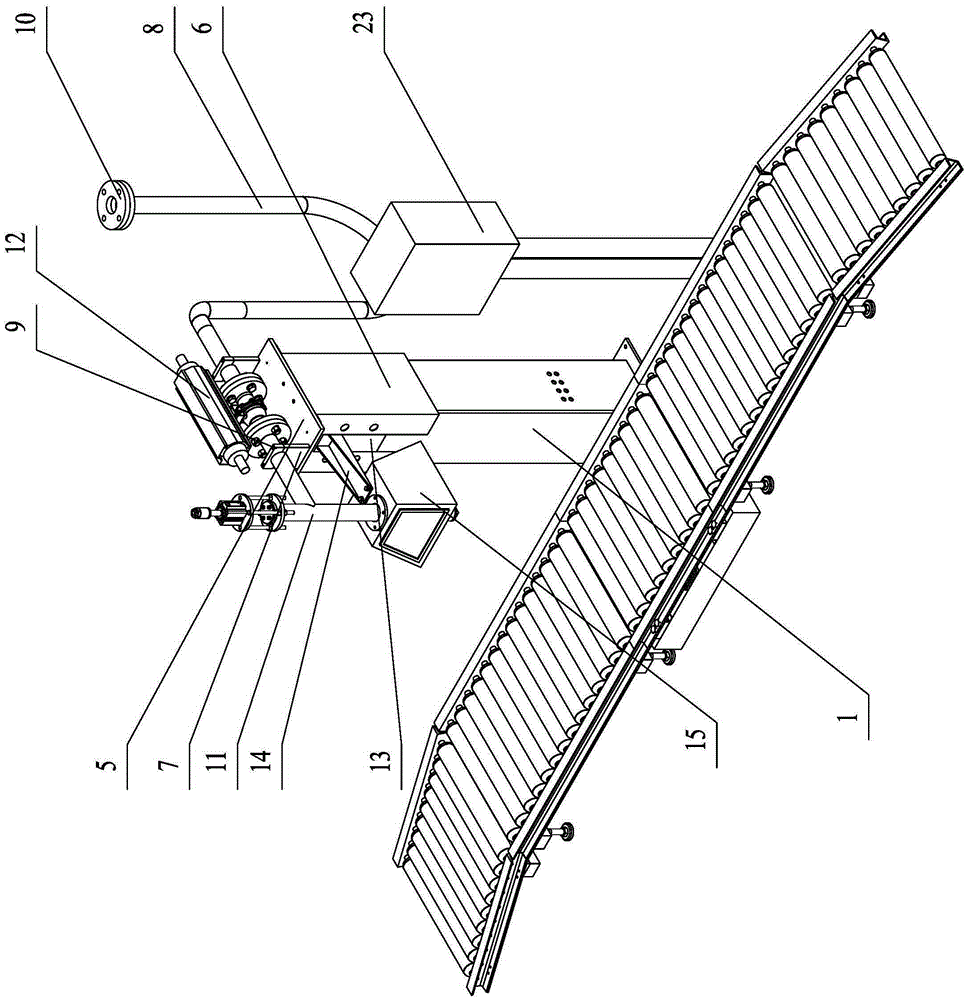

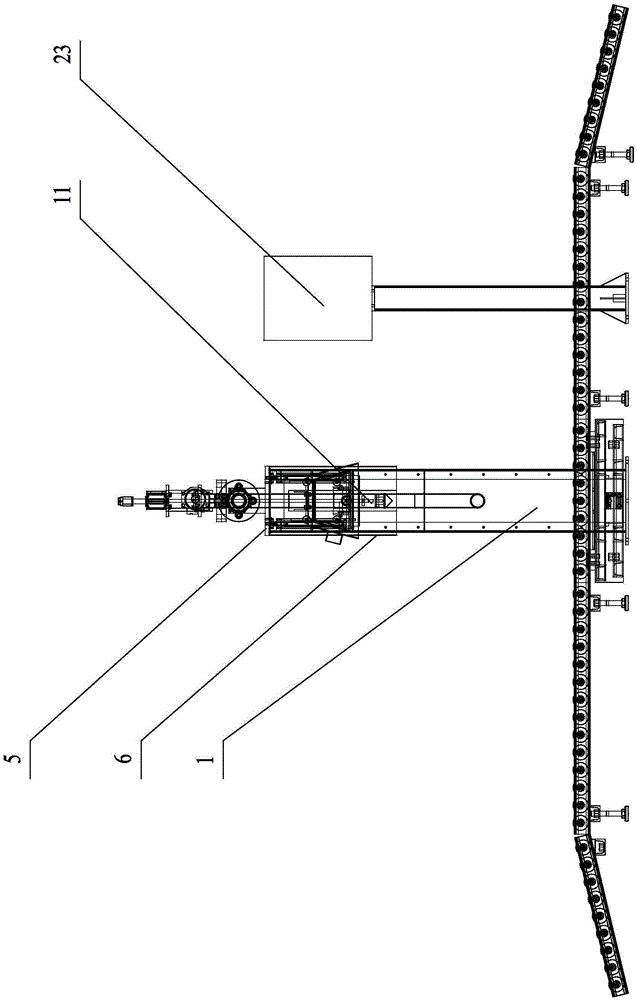

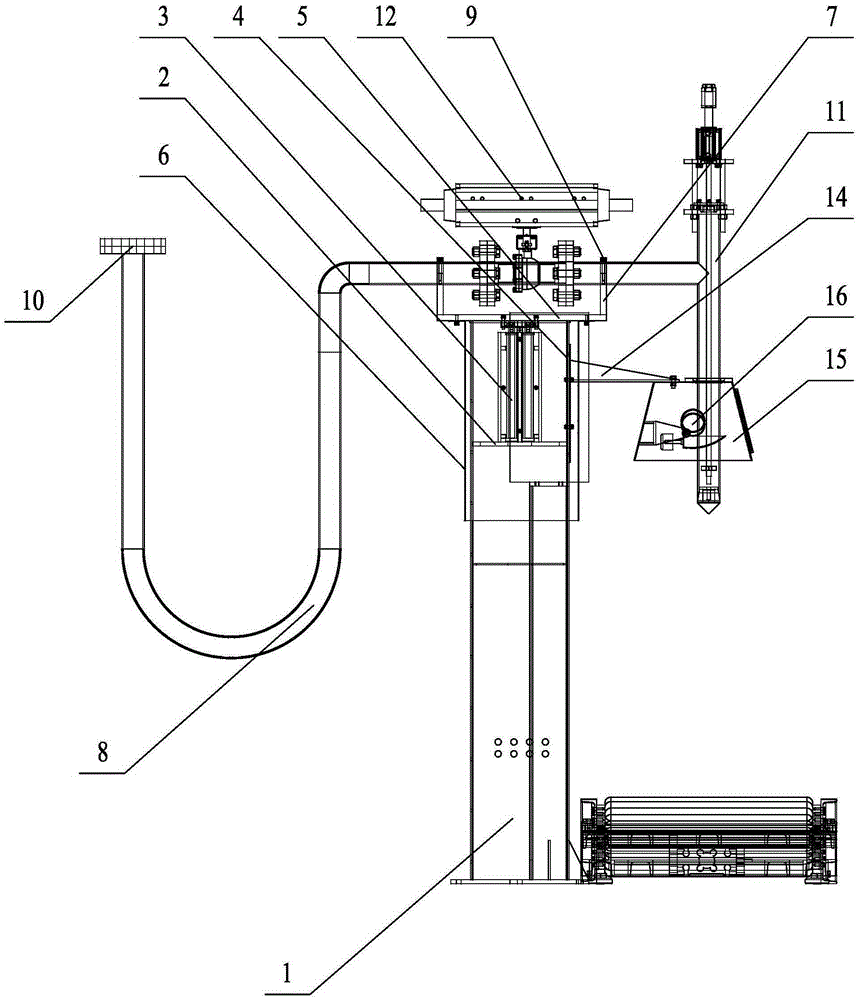

[0019] Such as Figure 1 to Figure 5 As shown: the filling equipment for preventing the volatilization and pollution of the filling liquid includes a filling frame 1, a cylinder support plate 2, a cylinder 3, a cylinder installation plate 4, a push plate 5, a casing 6, a support plate 7, and a metal hose 8. Support plate cover plate 9, flange 10, filling gun 11, two-stage ball valve 12, opening 13, gas collecting hood connecting plate 14, gas collecting hood 15, ventilation pipe connecting hole 16, first channel steel 17, The second channel steel 18, idler roller 19, fisheye joint 20, third channel steel 21, nylon universal foot cup 22, electric control cabinet 23, etc.

[0020] Such as Figure 1 ~ Figure 3 As shown, the filling equipment of the present invention includes a filling frame 1, an electric control cabinet 23 is installed on one side of the filling frame 1, a cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com