a use of k 2 nif 4 Apparatus and method for producing hydrogen by splitting water with structural oxygen-permeable membrane material

An oxygen-permeable membrane and water-splitting technology, applied in chemical instruments and methods, hydrogen production, hydrogen and other directions, can solve problems such as the difficulty of continuous hydrogen production by product separation, and achieve the effect of natural separation and separation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

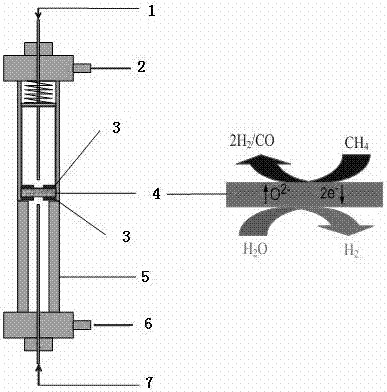

[0024] Such as figure 2 As shown, the use of K 2 NiF 4 A device for decomposing water to produce hydrogen with structural oxygen-permeable membrane materials, including reducing gas inlet 1, synthesis gas outlet 2, silver sealing ring 3, K 2 NiF 4 Structural oxygen permeable membrane 4, quartz reactor 5, hydrogen outlet 6 and water vapor inlet 7, quartz reactor 5 is a vertical reactor, and the middle position of quartz reactor 5 is provided with K 2 NiF 4 Structural Oxygen Permeable Membrane 4, K 2 NiF 4 The upper and lower sides of the structure oxygen permeable membrane 4 are provided with silver sealing rings 3, the upper half of the quartz reactor 5 is inserted into the reducing gas inlet pipe from the top, the lower half is inserted into the water vapor inlet pipe from the bottom, and the top of the methane inlet pipe is provided with a reducing gas inlet pipe. Inert gas inlet 1, water vapor inlet 7 at the bottom of the water vapor inlet pipe, synthesis gas outlet ...

Embodiment 2

[0029] Such as figure 2 As shown, the use of K 2 NiF 4 A device for decomposing water to produce hydrogen with structural oxygen-permeable membrane materials, including reducing gas inlet 1, synthesis gas outlet 2, silver sealing ring 3, K 2 NiF 4 Structural oxygen permeable membrane 4, quartz reactor 5, hydrogen outlet 6 and water vapor inlet 7, quartz reactor 5 is a vertical reactor, and the middle position of quartz reactor 5 is provided with K 2 NiF 4 Structural Oxygen Permeable Membrane 4, K 2 NiF 4 The upper and lower sides of the structure oxygen permeable membrane 4 are provided with silver sealing rings 3, the upper half of the quartz reactor 5 is inserted into the reducing gas inlet pipe from the top, the lower half is inserted into the water vapor inlet pipe from the bottom, and the top of the methane inlet pipe is provided with a reducing gas inlet pipe. Inert gas inlet 1, water vapor inlet 7 at the bottom of the water vapor inlet pipe, synthesis gas outlet ...

Embodiment 3

[0034] Such as figure 2 As shown, the use of K 2 NiF 4 A device for decomposing water to produce hydrogen with structural oxygen-permeable membrane materials, including reducing gas inlet 1, synthesis gas outlet 2, silver sealing ring 3, K 2 NiF 4 Structural oxygen permeable membrane 4, quartz reactor 5, hydrogen outlet 6 and water vapor inlet 7, quartz reactor 5 is a vertical reactor, and the middle position of quartz reactor 5 is provided with K 2 NiF 4 Structural Oxygen Permeable Membrane 4, K 2 NiF 4 The upper and lower sides of the structure oxygen permeable membrane 4 are provided with silver sealing rings 3, the upper half of the quartz reactor 5 is inserted into the reducing gas inlet pipe from the top, the lower half is inserted into the water vapor inlet pipe from the bottom, and the top of the methane inlet pipe is provided with a reducing gas inlet pipe. Inert gas inlet 1, water vapor inlet 7 at the bottom of the water vapor inlet pipe, synthesis gas outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com