Semiconductor laser pumped alkali metal laser system with V-type pump structure

A laser pumping, alkali metal technology, applied in gas laser parts, lasers, laser parts and other directions, can solve problems such as affecting the electro-optical efficiency of the DPAL system, affecting the output efficiency of the laser, and increasing the transmission loss of the resonator cavity. Stable output, improved overall electro-optical efficiency, small temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

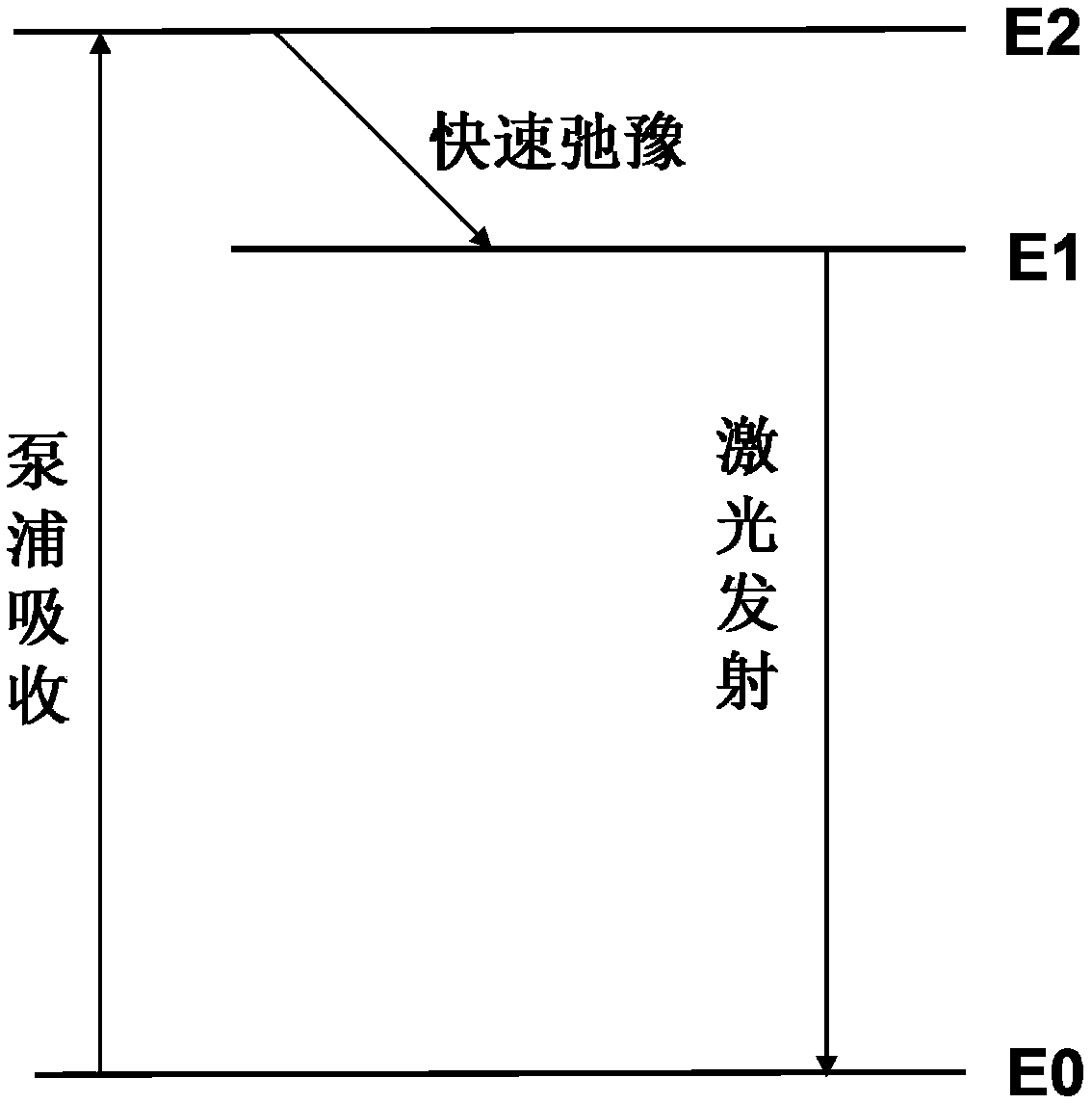

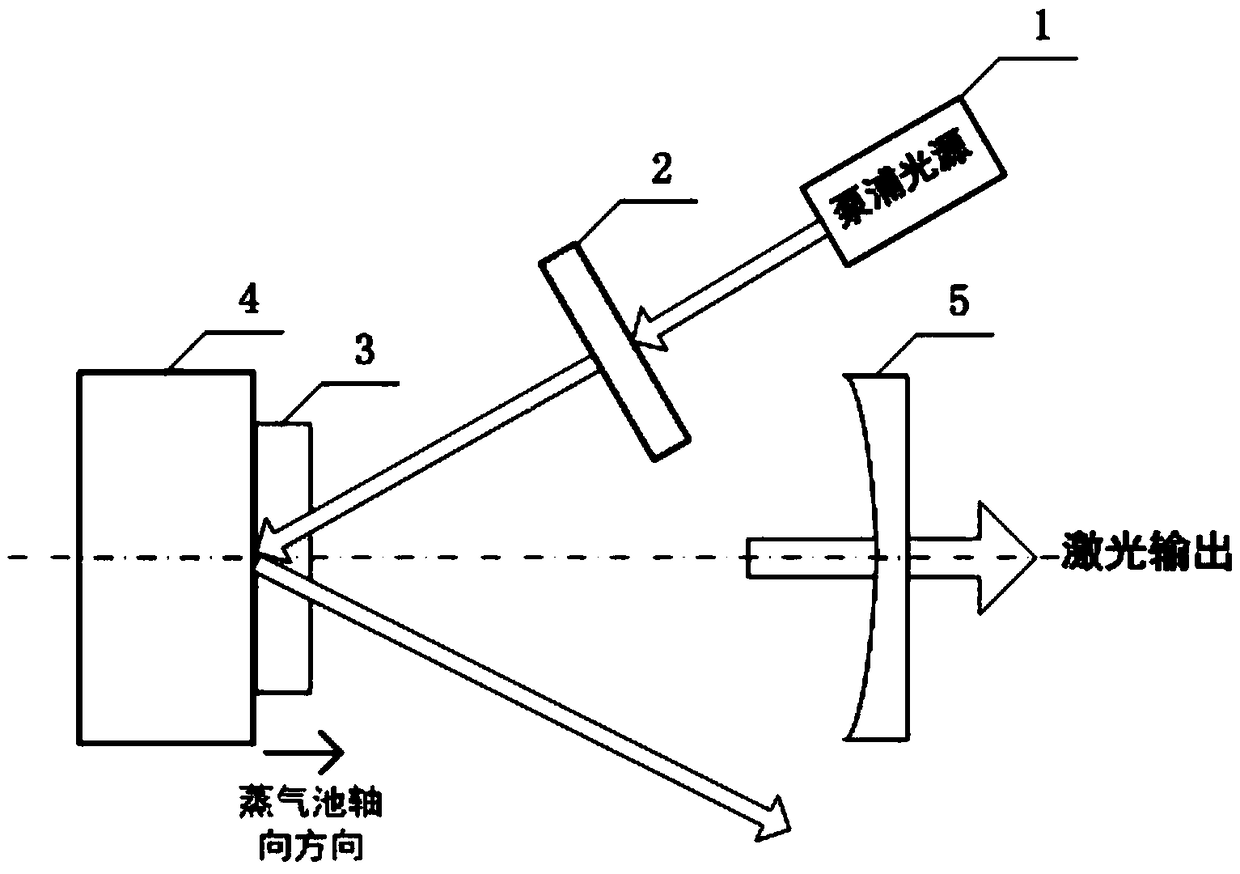

[0021] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention. In order to solve the problem that the pump light and laser are difficult to separate in the end-pumped DPAL, the present invention provides a semiconductor laser pumped alkali metal laser system with a V-shaped pump structure, refer to figure 2 As shown, for ease of description, only parts related to the structural embodiment of the present invention are shown.

[0022] The semiconductor laser pumped alkali metal laser system with a V-shaped pump structure in this embodiment includes: pump light source 1, beam homogenization collimation system 2, alkali metal vapor pool 3, temperature control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com