Tube type waste water treatment device and waste water treatment method

A waste water treatment, tubular technology, applied in multi-stage water treatment, water/sewage treatment, special compound water treatment, etc. Avoid the effects of current inefficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

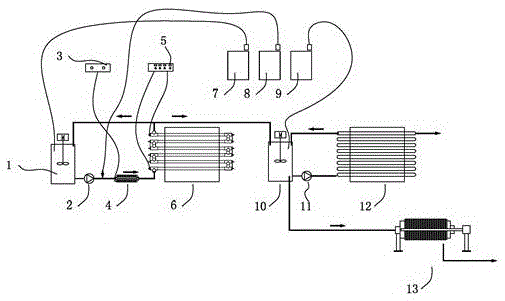

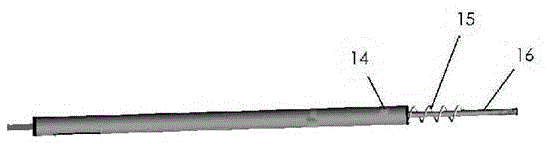

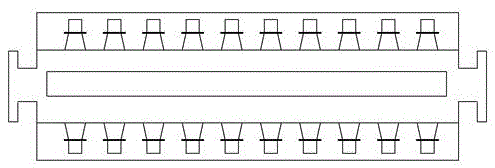

[0039] see Figure 1 to Figure 3, the present invention provides a tubular wastewater treatment device, which effectively integrates advanced oxidation technologies such as power ultrasonic, ultraviolet photocatalysis, induction electrofenton and heterogeneous catalytic oxidation, so that it can form a superimposed effect, while avoiding conventional electric Common shortcomings such as low reaction current efficiency, easy passivation of the plate, excessive consumption of the plate, and inconvenient replacement of the plate; in the entire scheme design, all units are designed as a tubular structure as much as possible, so that the entire device can be small Modularization, modularization and intelligence. The tubular wastewater treatment device mainly includes: a regulating tank 1, a first water pump 2, an ultrasonic generator 3, a tubular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com