Electrocatalytic reduction-oxidation reactor and method for pre-treating chlorobenzene waste water using same

An oxidation reactor and electrocatalysis technology, applied in chemical instruments and methods, electrochemical water/sewage treatment, water/sludge/sewage treatment, etc., to avoid secondary pollution, realize industrial automation, and low operation and maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

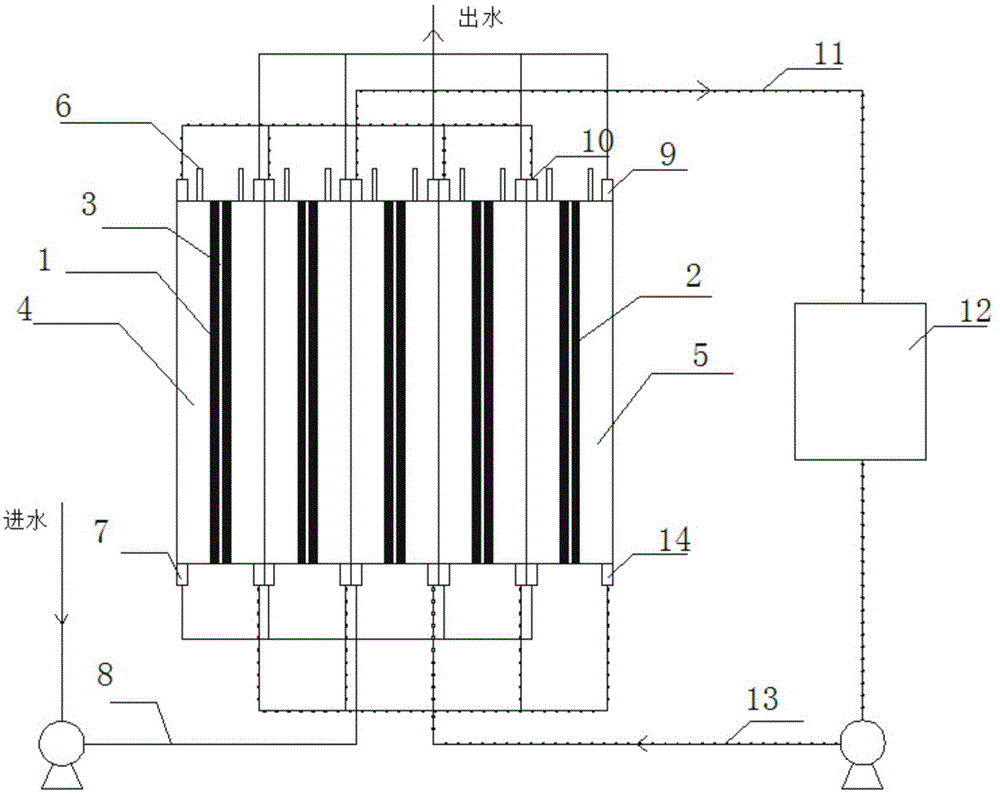

[0026] The electrocatalytic reduction-oxidation reactor that the present invention adopts is as shown in Figure 1, is made up of five closed containers, comprises cathode plate 1, anode plate 2, cation exchange membrane 3, cathode chamber 4, anode chamber 5, exhaust port 6. Cathode chamber water inlet 7, water inlet pipe 8, pump, anode chamber water outlet 9, cathode chamber water outlet 10, cathode chamber water outlet pipe 11, buffer tank 12, anode chamber water inlet pipe 13 and anode chamber water inlet 14; Each closed container includes a cathode chamber 4 and an anode chamber 5, and the cathode chamber 4 and the anode chamber 5 are separated by sequentially pasted cathode plate 1, anode plate 2 and cation exchange membrane 3, and the space near the cathode plate 1 is the cathode Chamber 4, the space near the anode plate 2 is the anode chamber 5; the exhaust port 6 is arranged at the top of the cathode chamber 4 and the anode chamber 5; the water inlet 7 of the cathode cha...

Embodiment 2

[0029] Adopted electrocatalytic reduction-oxidation reactor and embodiment are the same as example 1, and the waste water source is the same as example 1, and the difference is that the control current density is 15mA / cm 2, the residence time is 3h, the cathode plate 1 uses a titanium plate, and the anode plate 2 uses a titanium electrode coated with iridium oxide. The pH of the wastewater is adjusted to 2 before treatment. After treatment, the COD of chlorobenzene wastewater was less than 500mg / L, the concentration of chlorobenzene was less than 1.5mg / L, the relative inhibition rate of acute toxicity of luminescent bacteria was 6.2%, and the B / C of wastewater increased to 0.41. The treated tail water is discharged directly or further treated.

Embodiment 3

[0031] Adopted electrocatalytic reduction-oxidation reactor and embodiment are the same as example 1, and the waste water source is the same as example 1, and the difference is that the control current density is 20mA / cm 2 , the residence time is 2h, the cathode plate 1 uses a titanium plate loaded with ruthenium oxide, the anode plate 2 uses a titanium electrode coated with iridium oxide, and the pH of the wastewater is not adjusted before treatment. After treatment, the COD of chlorobenzene wastewater was less than 540mg / L, the concentration of chlorobenzene was less than 2.0mg / L, the relative inhibition rate of acute toxicity of luminescent bacteria was 7.1%, and the B / C of wastewater increased to 0.39. The treated tail water is discharged directly or further treated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com