A device for heat treatment of springs

A compression spring and clamping technology, which is applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve problems that affect processing efficiency and product quality, long calibration time, spring deformation, etc., to reduce processing costs, improve processing efficiency, The effect of eliminating the correction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below.

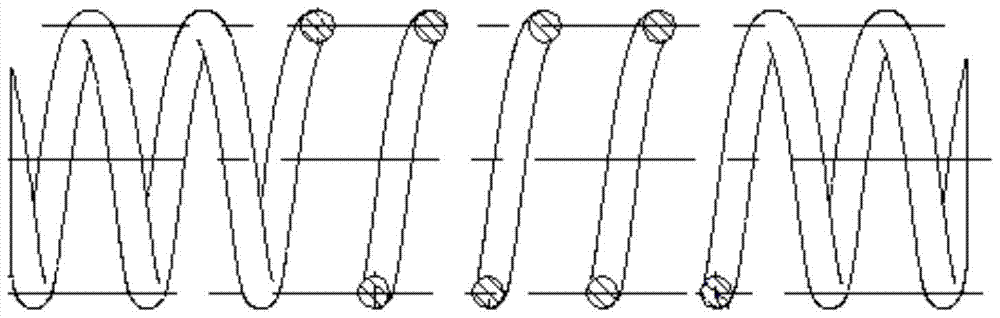

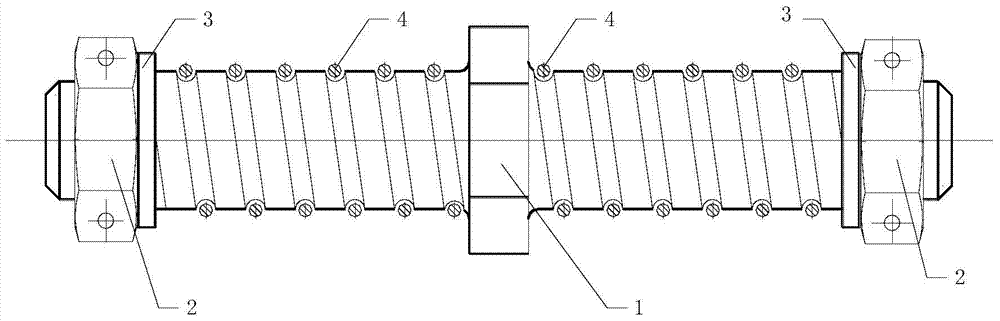

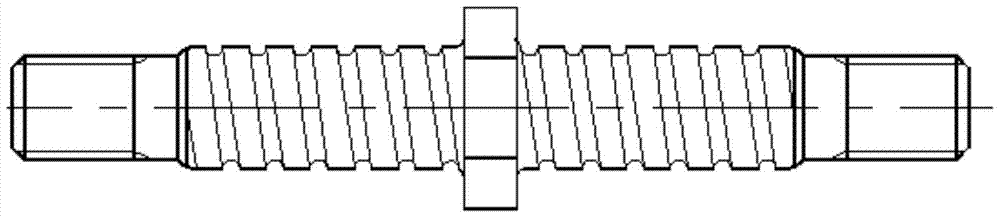

[0018] refer to figure 2 , the schematic diagram of the structure of the device for the heat treatment of cylindrical helical compression springs in the clamped state according to the present invention, the device includes a screw 1, a nut 2 and an arc-shaped circular washer 3, the screw 1 has a hexagonal stop in its middle, and will need The heat-treated spring 4 is screwed in from both ends of the screw rod 1 along the groove, and then the arc-shaped circular washer 3 and the nut 2 are respectively screwed on from the outside, and the arc-shaped circular washer 3 is adjusted to ensure the accurate positioning of the end of the spring. Nut 2 is fixed.

[0019] When put into the heat treatment furnace, use thin iron wire to penetrate the two non-threaded holes of the nut 2 to realize the binding of the device, then hang it into the heat treatment furnace, and then heat treatment production can be carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com