Herstellungsverfahren FooR Hartes Gleitelement

A technology of sliding parts and manufacturing methods, applied in metal material coating process, vacuum evaporation coating, coating and other directions, can solve the problems such as difficulty in improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below, while referring to the attached Figure 1 Embodiments of the present invention will be described in more detail.

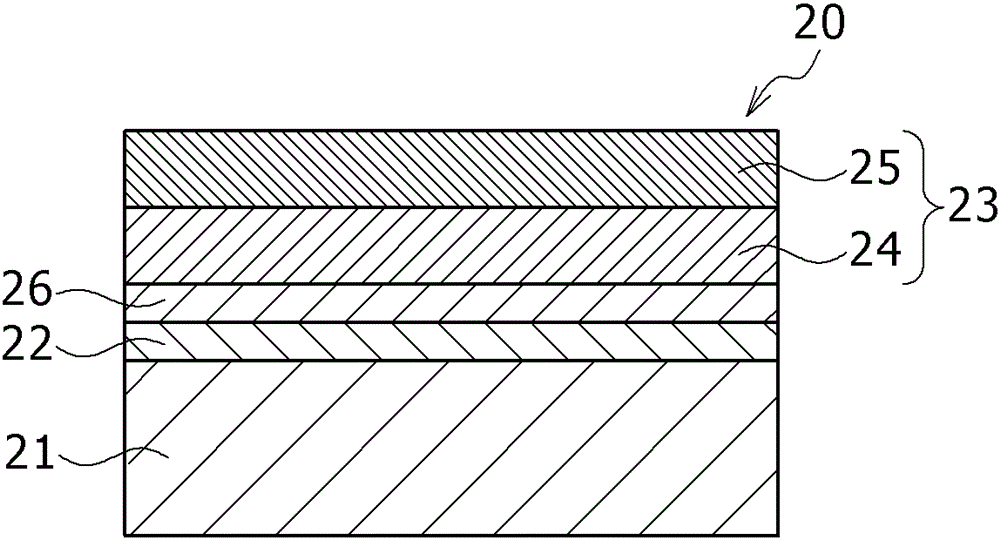

[0035] figure 1 A hard sliding member 20 (for example, engine parts such as pistons and cylinders, cutting tools, etc.) manufactured by this embodiment is shown. Specifically, the method of manufacturing the hard sliding member 20 is to form the carbon film 23 having a hardness higher than that of the base material 21 by AIP after surface treatment of the base material 21 (for example, formation of the base layer 22 , etc.).

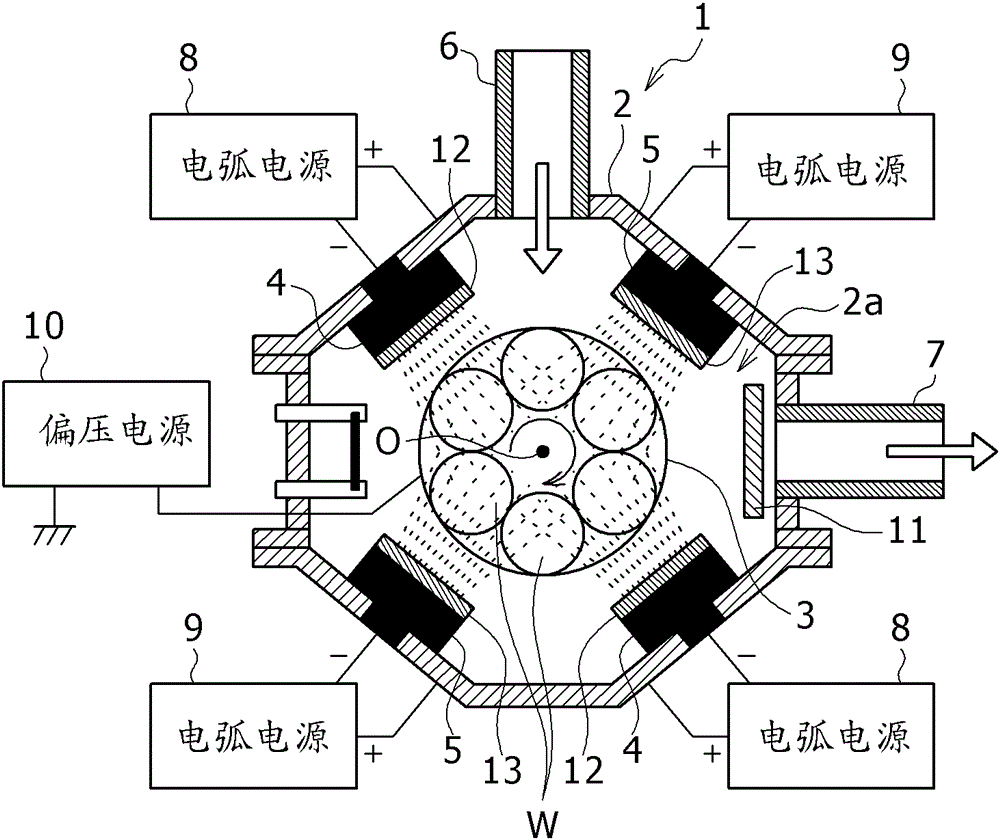

[0036] The manufacturing method includes: one side into the chamber, for example figure 2 The carbon film 23 is formed in the chamber 2 by AIP while introducing a hydrocarbon gas into the chamber 2 of the film forming apparatus 1 shown, and by reducing the introduction amount of the above-mentioned hydrocarbon gas in the AIP, the carbon film 23 is controlled. 23 hardness (that is, internal stress), so that the hardness of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com