Table rack for sewing machine

A sewing machine and trigger technology, applied in sewing machine components, sewing equipment, textiles and papermaking, etc., can solve the problems of unsmooth push and pull of drawer boxes, cumbersome installation, no installation position indication, etc., to reduce installation time and labor intensity, avoid Push-pull is not smooth, the connection is reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

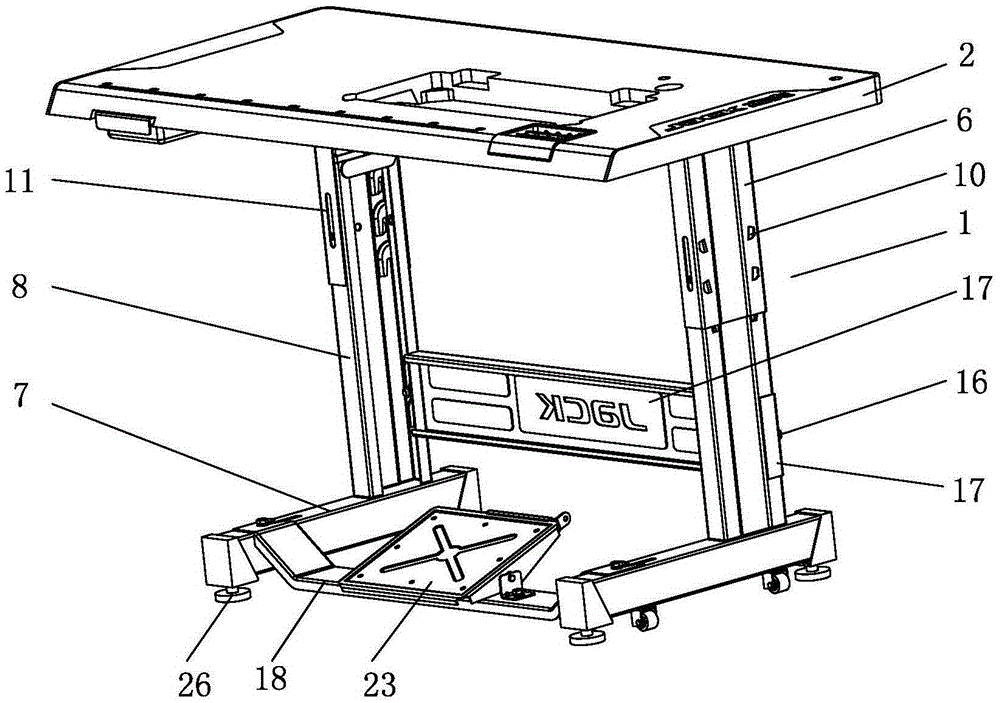

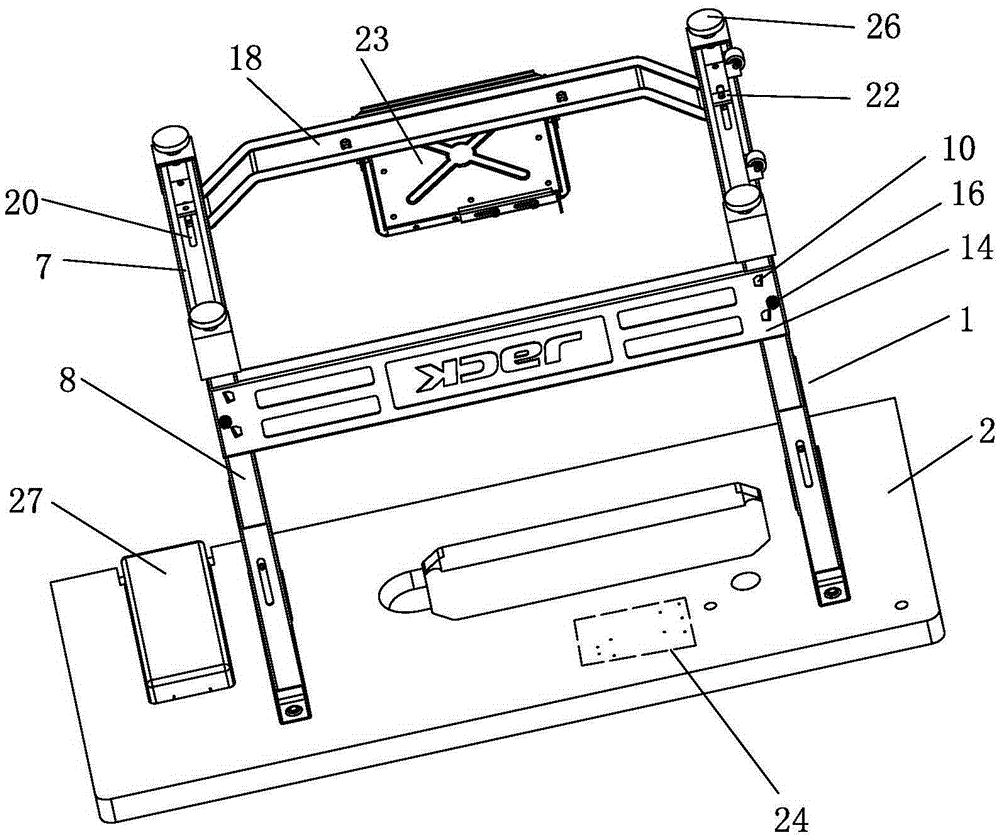

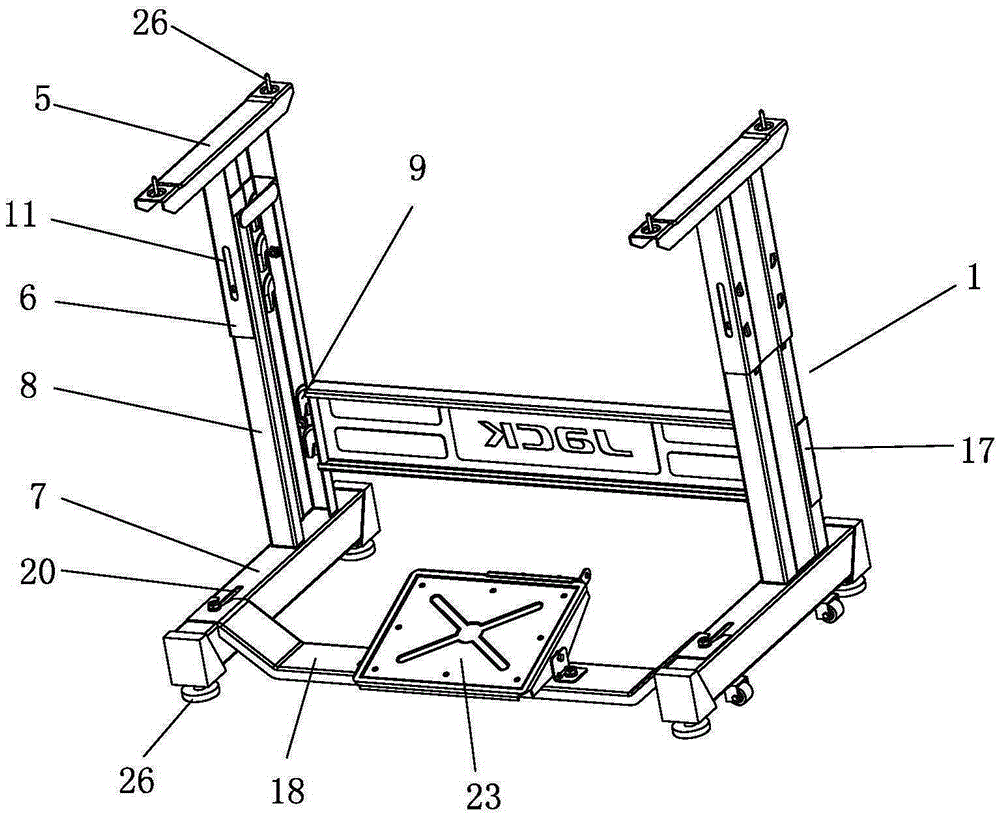

[0029] The present invention will be further described below with specific embodiment, see figure 1 -8:

[0030] A kind of sewing machine platen frame, comprises frame 1 and the platen 2 that is arranged on the frame, described frame 1 comprises the left frame and the right frame that left and right intervals are arranged, left frame, right frame The frame is composed of an upper section 3 and a lower section 4 respectively, the upper section 3 includes an upper section horizontal part 5 and an upper section vertical section 6, the lower section 4 includes a lower section horizontal section 7 and a lower section vertical section 8, and the lower section The vertical part 8 is provided with more than one set of card slots 9. In this embodiment, there are two groups arranged at intervals up and down. Each group includes two card slots 9. The number of sets of card slots can also be adjusted according to the actual situation. The upper vertical part 6 is provided with a hook 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com