Foundation pit anti-seepage and settlement control method based on stereoscopic curtain-well group system

A technology of settlement control and group system, which is applied in the field of geotechnical engineering and geological engineering, and can solve problems such as substandard foundation pit drawdown, difficult construction, and aggravated settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

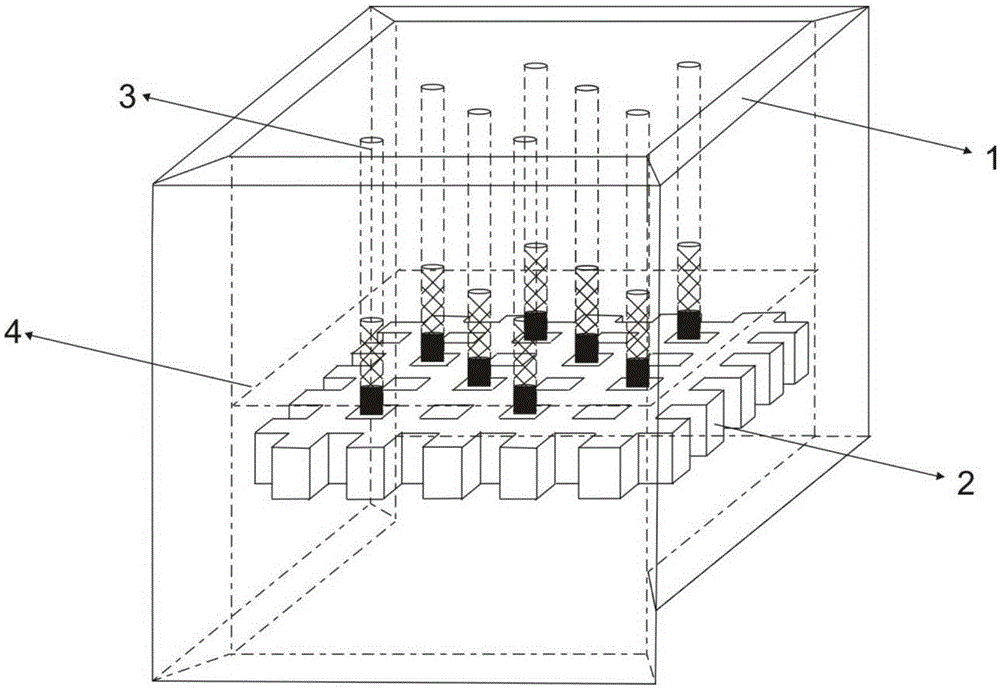

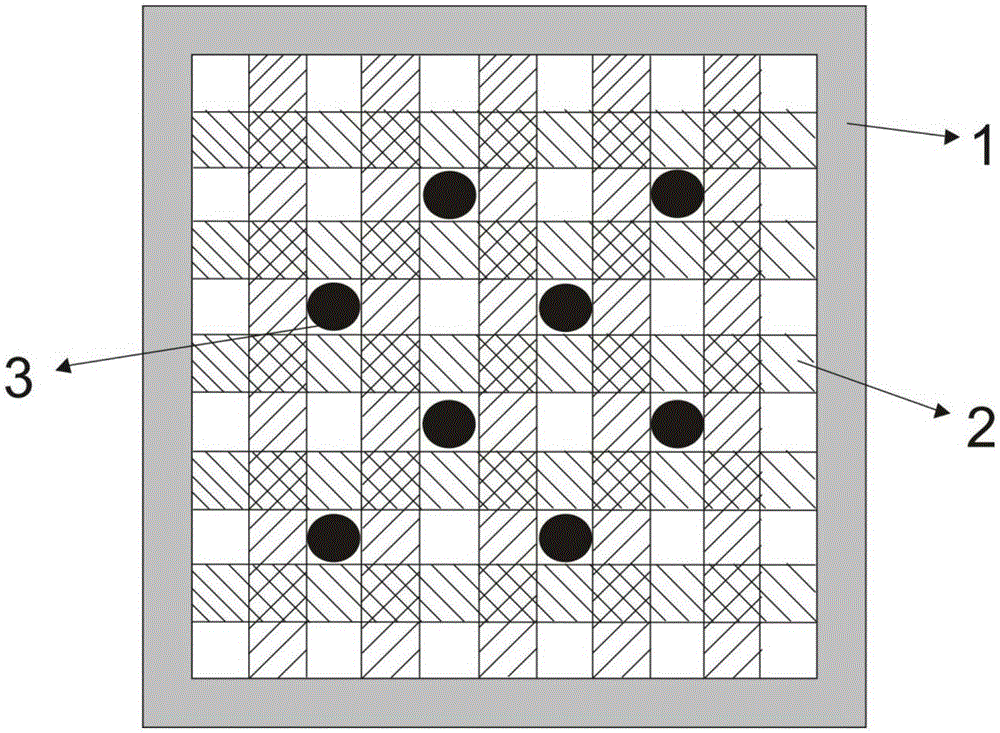

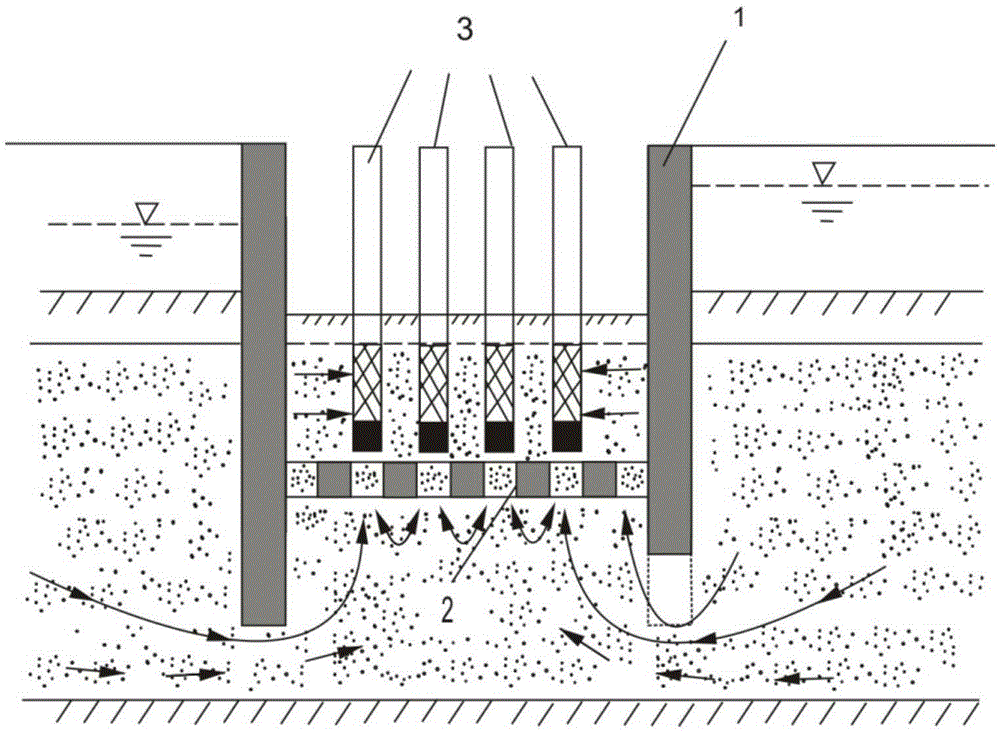

[0026] In a specific example, such as figure 1 As shown, the vertical unequal-depth curtain 1 construction is carried out firstly. For deep foundation pits, an underground diaphragm wall can usually be used. To the curtain 1. The horizontal curtain grid 2 can adopt methods such as high-pressure rotary spraying, MJS, grouting, etc., so that it does not join together with the vertical curtain 1 of unequal depth with a large thickness and strength, and the horizontal curtain grid 2 is located below the bottom surface 4 of the foundation pit , less than 1m from the bottom of the foundation pit, it plays a part of water blocking in the vertical direction of the foundation pit. The well group system 3 arranges the pumping wells in the foundation pit with a fixed well spacing according to the uniform layout method. Due to the increase of the horizontal curtain, its number will be much smaller than that under the condition of no horizontal curtain, and the dewatering well should be l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com