Method for exploiting coalbed methane by adopting active water displacement

A technology of active water flooding and coalbed methane, which is applied in the fields of mining fluid, earthwork drilling, wellbore/well components, etc., and can solve the problems of inability to use coalbed methane for large-scale commercial development, complicated production stimulation process, and difficult construction. Achieve the effects of solving the problem of coalbed methane well produced water treatment, saving engineering investment, and facilitating construction operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Such as figure 1 , figure 2 , image 3 As shown, the active water displacement method for exploiting low-permeability coalbed methane includes the following steps:

[0028] S1: According to the development data of coalbed methane blocks, the selected well pattern is relatively regular, the drainage time is more than 3 years, and the average daily water production of a single well is less than 10m 3 1. Rectangular well pattern units with no gas seen in central coalbed methane wells or whose daily gas production is lower than economic daily gas production are used as measure well groups;

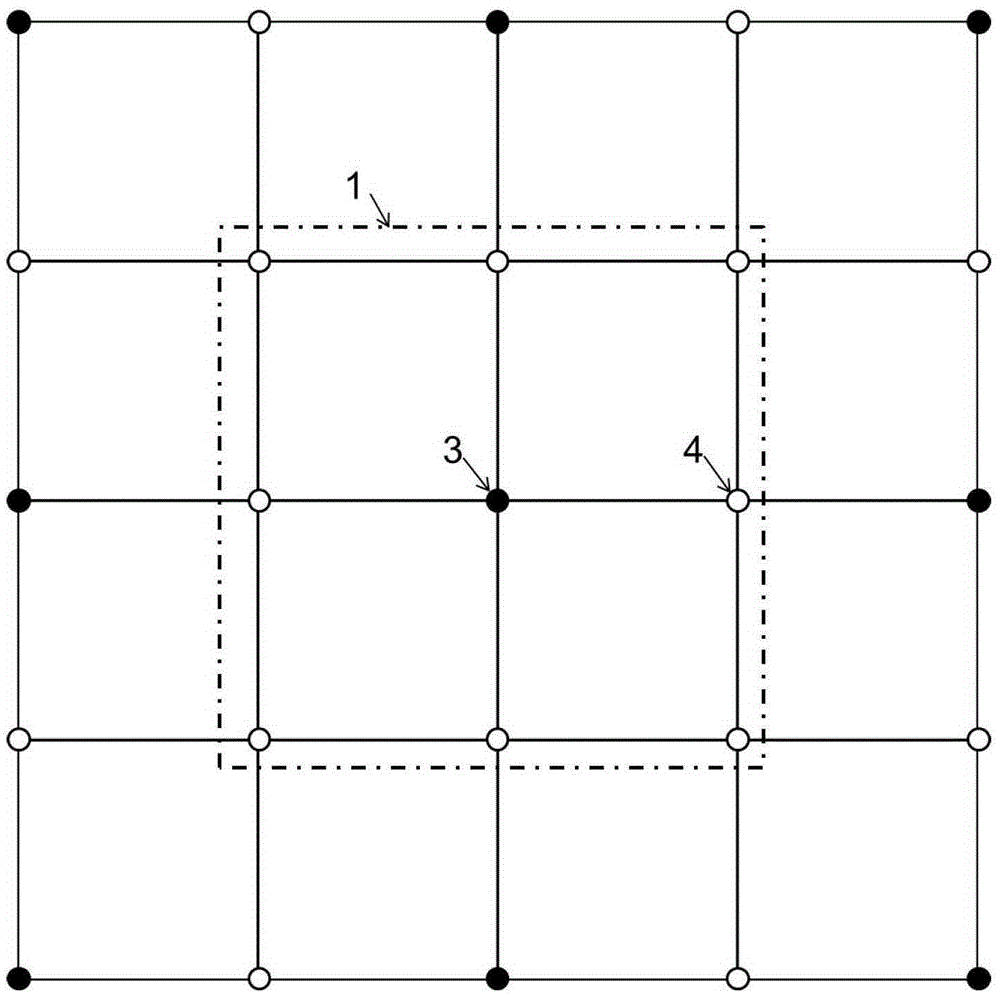

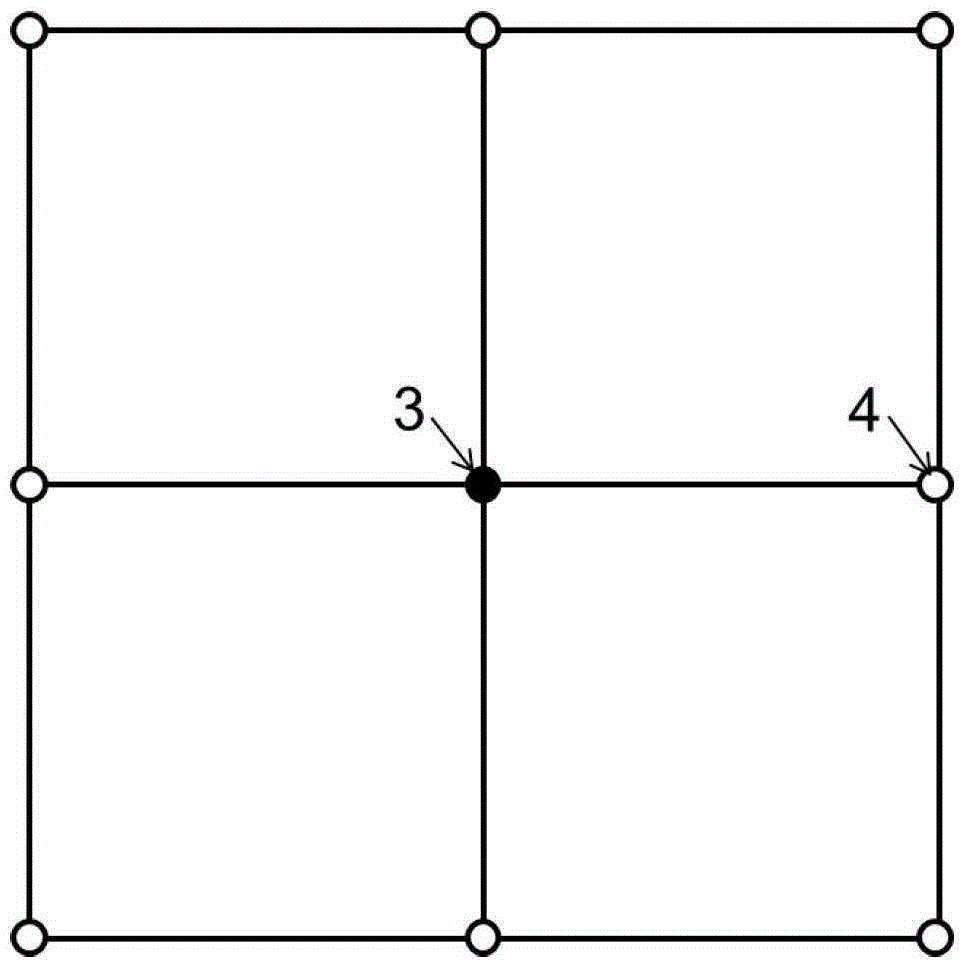

[0029] For such as figure 1 For the CBM rectangular well pattern shown, a rectangular well pattern unit 1 consisting of a unit central well 3 and 8 coalbed methane production wells adjacent to the unit central well 3 is selected (such as figure 2 ), implementing transfer injection displacement mining;

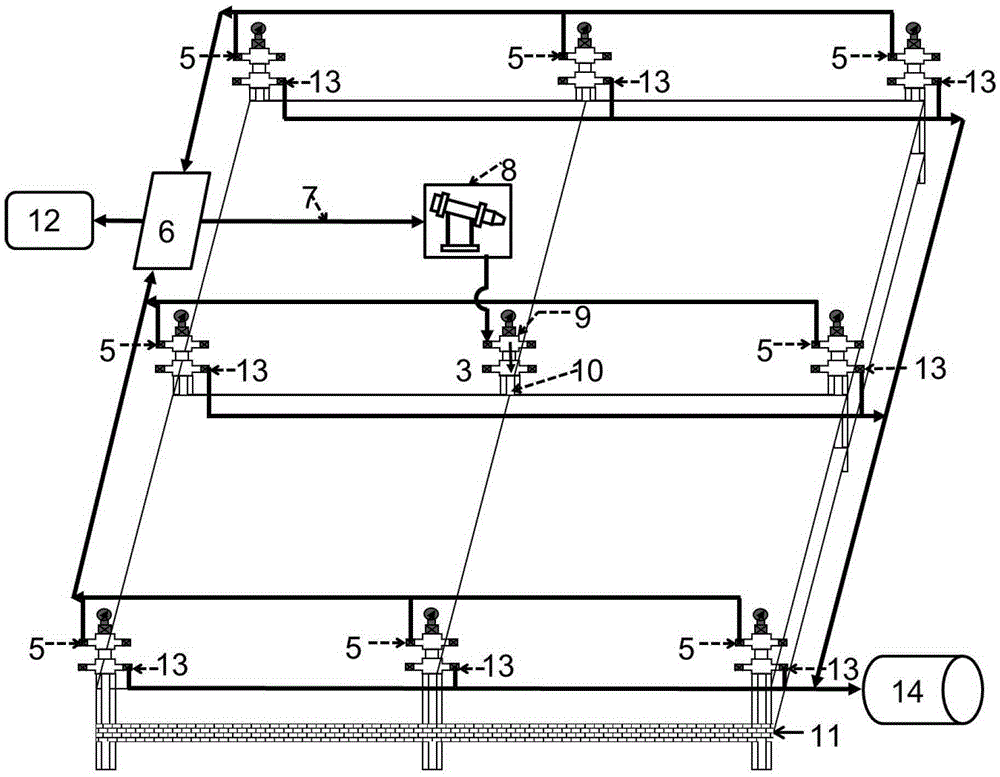

[0030] S2: Replace the water injection wellhead device 9 on the unit center w...

Embodiment 2

[0038] Such as Figure 4 , Figure 5 , Figure 6 As shown, the active water displacement method for exploiting low-permeability coalbed methane includes the following steps:

[0039] S1: According to the development data of coalbed methane blocks, the selected well pattern is relatively regular, the drainage time is more than 3 years, and the average daily water production of a single well is less than 10m 3 , The central coalbed methane well has no gas or the diamond-shaped well pattern unit whose daily gas production is lower than the economic daily gas production is used as the measure well group;

[0040] For such as image 3 In the diamond-shaped CBM well pattern shown, the diamond-shaped well pattern unit 2 composed of the unit center well 3 and 6 coalbed methane production wells adjacent to the unit center well 3 is selected (such as Figure 4), implementing injection displacement mining;

[0041] S2: Replace the water injection wellhead device 9 on the unit center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com