Splicing structure used for combined type tunnel lining, culvert or comprehensive pipe gallery

A comprehensive pipe gallery and combined technology, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of affecting the appearance, reducing the passage space of the pipeline, collision or scratching, etc., to increase the internal passage space and the amount of engineering excavation The effect of reduction and reduction of cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical scheme of the present invention will be further described below in conjunction with the drawings.

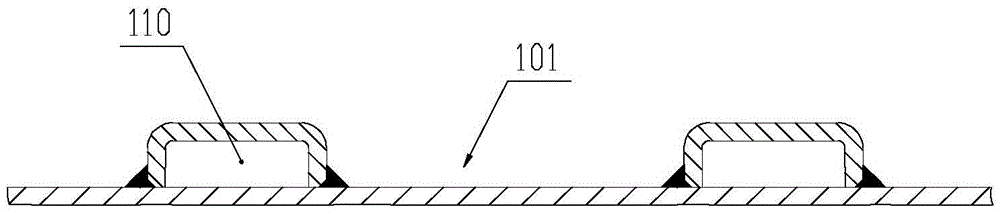

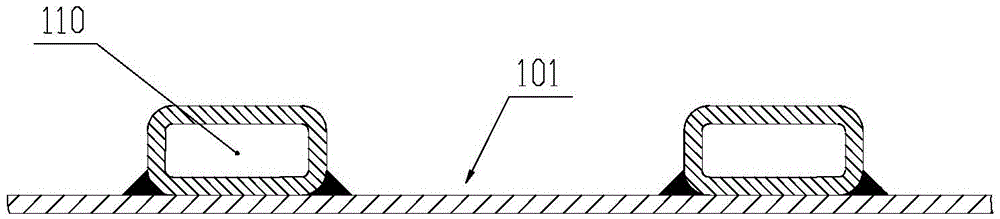

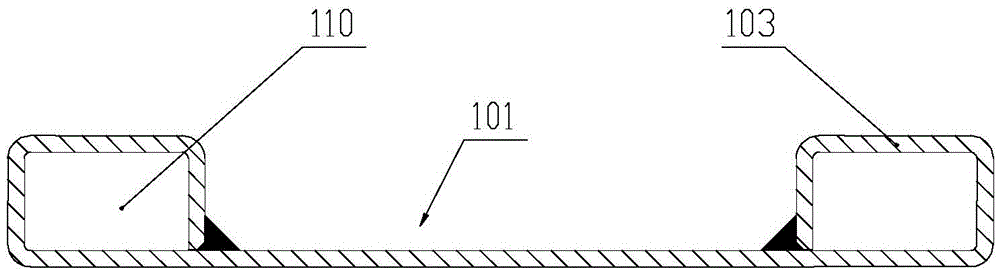

[0022] The splicing structure of the present invention includes the unit plates 101 being assembled in the circumferential direction to form a pipe section 102, which is spliced along the axial direction to form a tunnel lining or culvert 100; wherein, when the pipe section 102 is spliced in the axial direction, adjacent unit plates The contact ends of the sheet 101 each have a folded edge 104 or a hollow cavity structure 110 that is turned to the outside of the pipe section. The cross section of the hollow cavity structure 110 is closed and the adjacent folded edge 104 or the hollow cavity structure 110 is in contact The surface is the splicing connection surface, such as Picture 9 , 10 Shown. Preferably, the contact surface can be connected by a workpiece such as a bolt. Since the hemming or hollow cavity structure is located outside of the tunnel, culv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com