Large-clearance modular lining trolley for tunnel

A lining trolley, modular technology, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of large area of lining trolley, obstruction of tunnel air circulation, poor tunnel air circulation, etc., to improve construction efficiency, The structure is firm and reliable, and the effect of increasing the clearance under the trolley

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

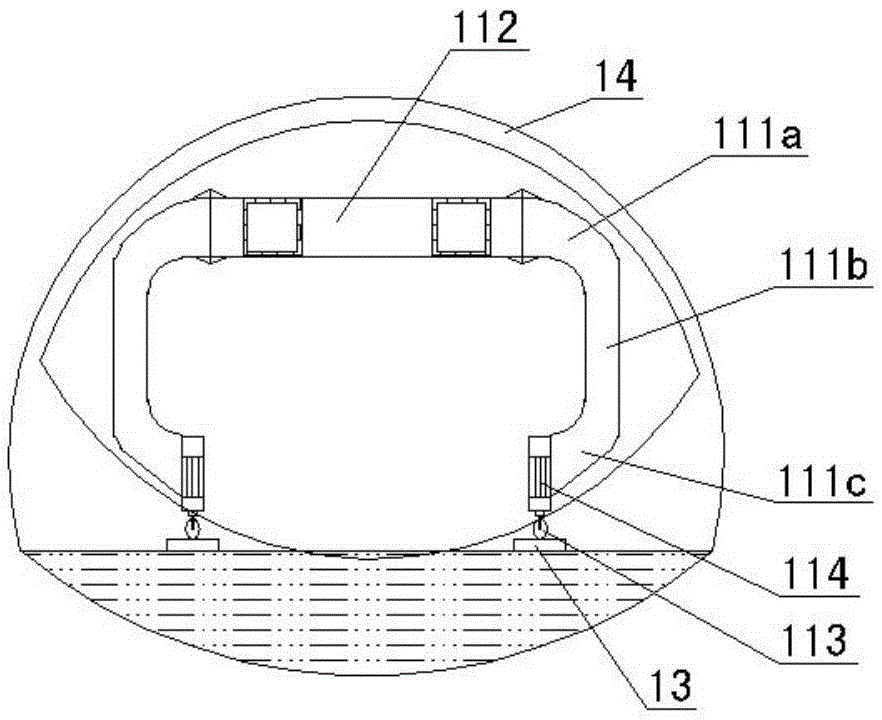

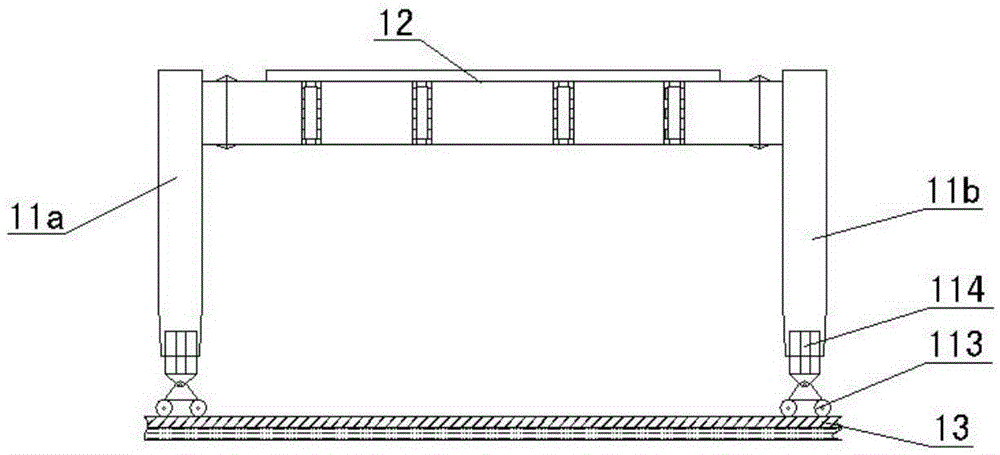

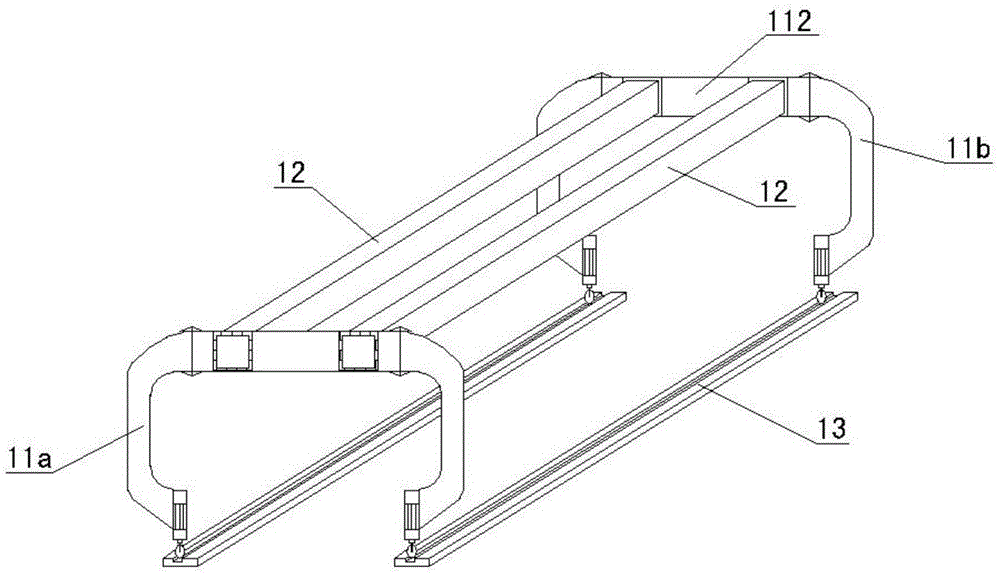

[0031] In this embodiment, the tunnel large-clearance modular lining trolley is composed of a modular lining trolley portal frame, a lining trolley portal frame support structure, an adjustable formwork for the lining trolley, a lining trolley formwork support system and a ventilation system.

[0032] see Figure 1A , Figure 1B with Figure 1C , the structural form of the lining trolley gantry in this embodiment is: an arched gantry is provided, which is connected by a top beam 112 between two left and right columns, and the column has an upper curved section 111a, a middle vertical section 111b and a lower section For the "C" shape of the curved section 111c, the left and right columns are opposite to the opening side of the "C" shape, and the back of the "C" shape is arched towards the side wall of the tunnel on the side where the column is located; the arch Shaped gantry is two, is respectively front door frame 11a and rear door frame 11b, and the top longitudinal beam 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com