Lateral volute steam inflow type low-pressure inner cylinder for steam turbine

A steam turbine and side technology, which is applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of poor fluidity and unsmooth steam inlet passage, and achieve the effect of ensuring safe operation, compact structure and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

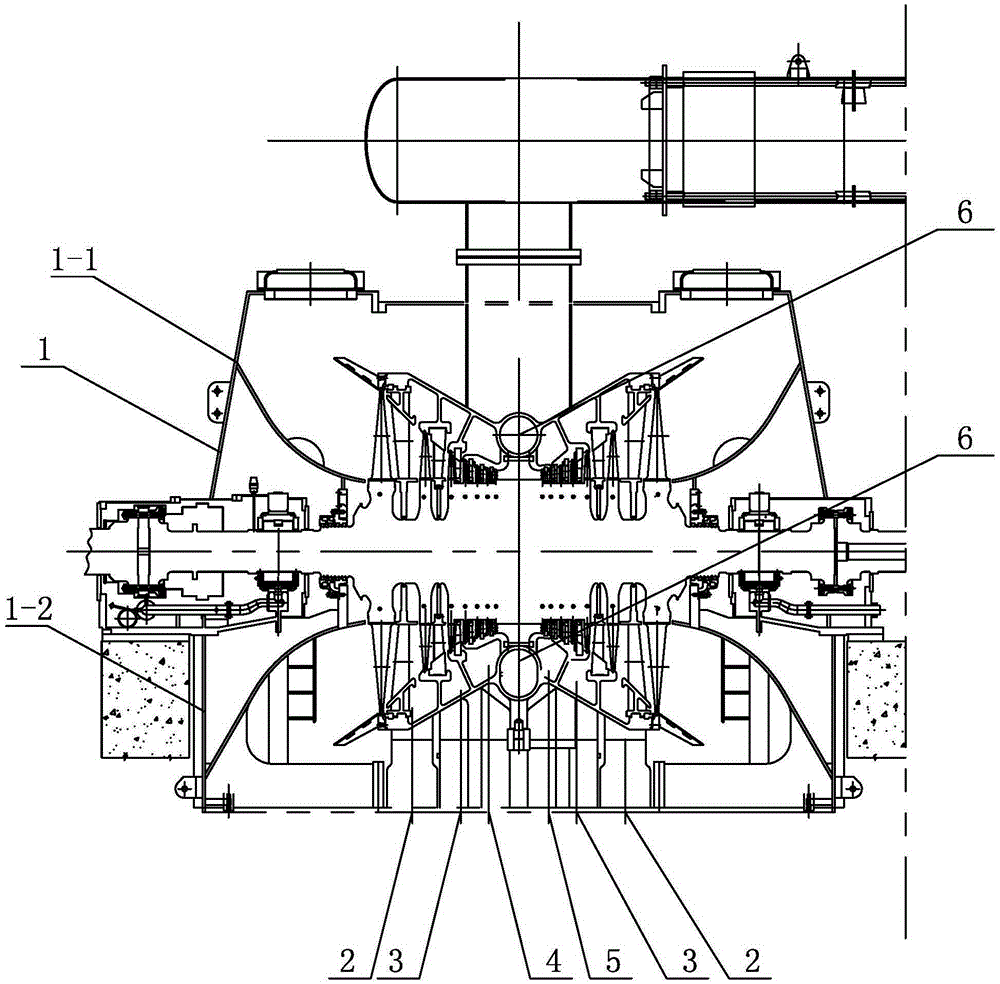

[0009] Specific implementation mode one: combine figure 1 Describe this embodiment, the side volute steam intake type low-pressure inner cylinder for a steam turbine described in this embodiment includes an inner cylinder body 1, and the inner cylinder body 1 is composed of an upper cylinder body 1-1 and a lower cylinder body 1-1. 2 Form an integrated large inner cylinder structure, the bottom of the lower cylinder 1-2 is provided with eight-stage air outlet 2, seven-stage air outlet 3, six-stage air outlet 4, five-stage air outlet 5, and seven-stage air outlet from left to right Air extraction port 3, eight-stage air extraction port 2.

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the upper cylinder body 1-1 and the side of the lower cylinder body 1-2 of a side volute steam-inlet low-pressure inner cylinder for a steam turbine described in this embodiment are both provided with air inlets 6 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0011] Specific implementation mode three: combination figure 1 Describe this embodiment, the inner cylinder body 1 of a side volute steam inlet type low-pressure inner cylinder for a steam turbine described in this embodiment is a scroll type low-pressure inner cylinder body. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com