Combustion engine, in particular gas engine, for a vehicle, in particular for a commercial vehicle

一种内燃机、商用车的技术,应用在尤其燃气发动机,能够解决污物敏感性易受干扰等问题,达到可靠成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

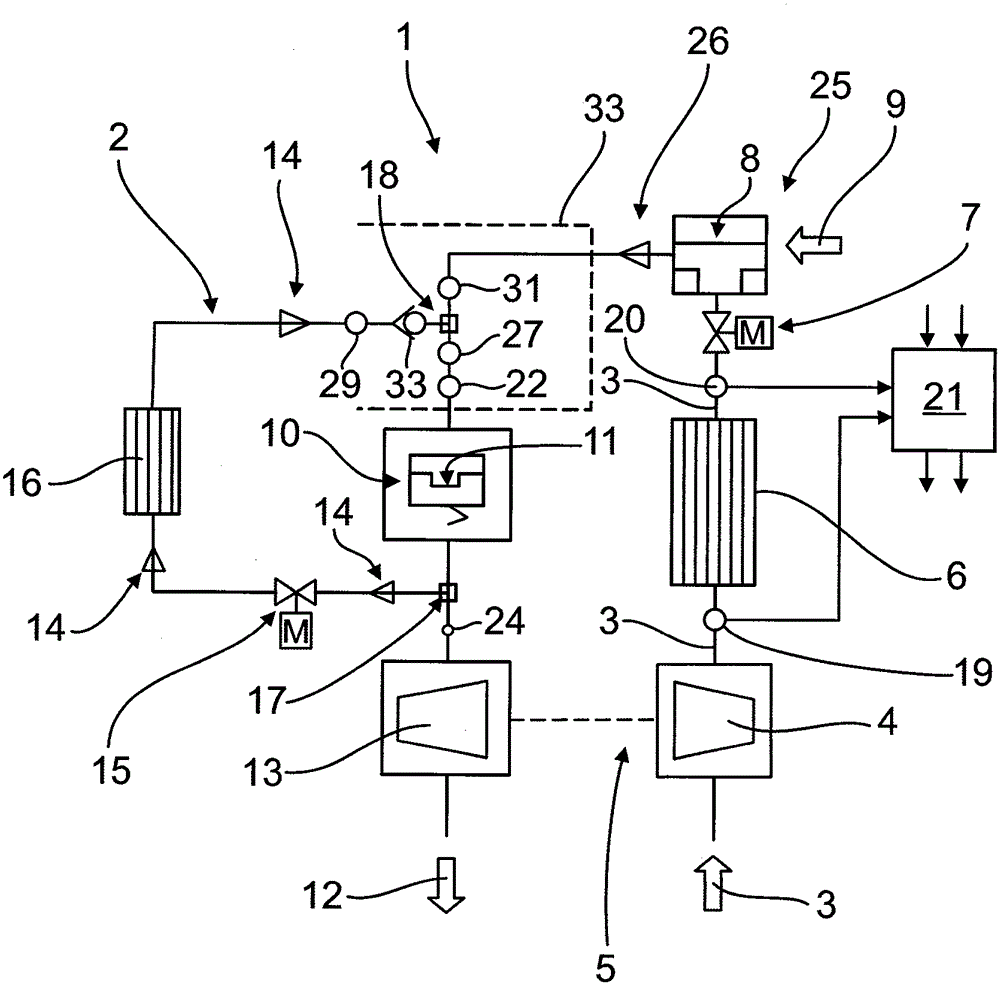

[0074] The air mass flow (arrow 3 ) is supplied to the engine block 10 via the intake tract 25 , wherein the air mass flow 3 here first flows through the compressor 4 (which is a component of the exhaust gas turbocharger 5 ) and then through the Charge air cooler 6. From there, the cooled air mass flow 3 flows via a controllable throttle valve 7 to a gas mixer 8 , to which a natural gas mass flow (arrow 9 ) is additionally fed. From the gas mixer 8 , the natural gas-air gas mixture 26 formed there flows to the cylinder-piston unit 11 , in which the combustion process takes place. The exhaust gas mass flow (arrow 12 ) then flows through the turbine 13 of the exhaust gas turbocharger 5 , wherein the turbine 13 is mechanically coupled to the compressor 4 and drives the compressor 4 .

[0075] Upstream of the turbine 13 , controlled via an AGR control valve 15 , a part of the exhaust gas mass flow is branched off at a branch point 17 as an AGR mass flow 14 . This AGR mass flow 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap