Method for measuring fiber density

A method of measuring fiber density, which is applied in the field of fiber density measurement, can solve the problems that distilled water is difficult to completely infiltrate the fiber, affects the fiber's full immersion, and the addition of distilled water is limited, so as to achieve accurate and reliable measurement, accurate and stable test results, and high density. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with specific examples, but the present invention is not limited to these examples.

[0026] Select A, B two kinds of lignin fibers of different manufacturers, respectively adopt the assay method of the present invention and pycnometer to measure.

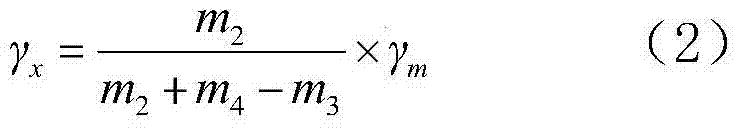

[0027] Adopt the measuring method of fiber density of the present invention to measure the density of A, B two kinds of lignin fibers respectively, specifically comprise the following steps:

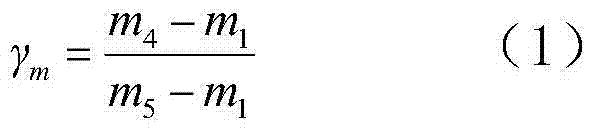

[0028] Step 1, take a clean and dry volumetric flask, weigh the mass of the volumetric flask, and record it as m 1 .

[0029] Step 2, take A or B lignin fiber, weigh the fiber mass, record it as m 2 ; Put the fiber into the volumetric flask, and then inject kerosene into the volumetric flask until the liquid level of kerosene is close to the scale line of the volumetric flask; soak the fiber in kerosene for 16 hours, then place the volumetric flask in a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com