Large test run hanging bracket with adjustable balance weight space

A space and large-scale technology, applied in the direction of counterweight, spring/shock absorber design, spring, etc., can solve problems such as increasing load, achieve uniform force, wide weight range, and prevent deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

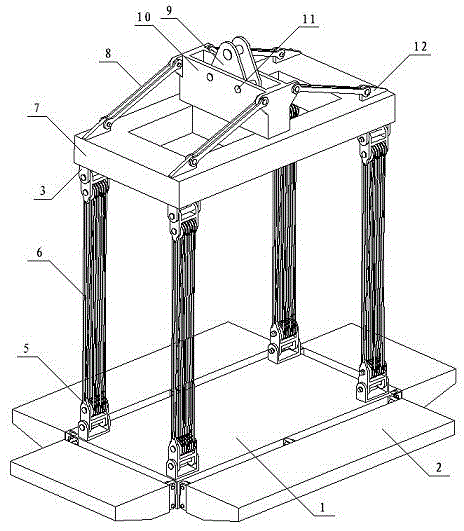

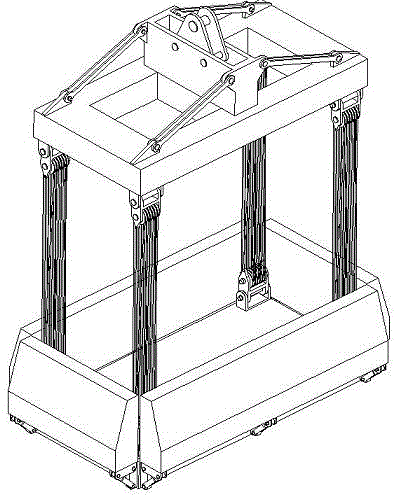

[0014] Below in conjunction with accompanying drawing, the present invention is described in further detail:

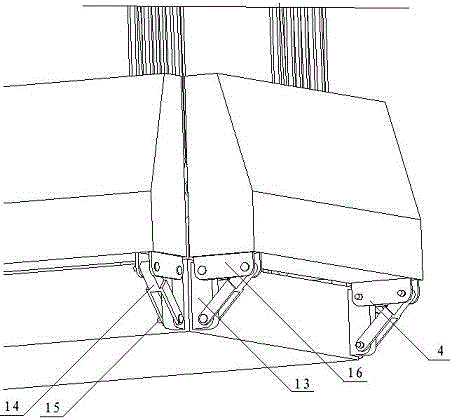

[0015] Such as figure 1 , 2 As shown, the large-scale test hanger provided in this embodiment is mainly composed of a hook connecting part 9, an upper welded box 7, a weight frame 1, and upper and lower pulley assemblies. The upper and lower pulley assembly is made of pulley frame 3, block pulley 5 and steel wire rope 6. The upper welded box type is a frame structure with a hollow in the middle, and a mounting frame 10 is connected to the middle position of the top, and the hook connecting part is connected to the mounting frame through a pin shaft 11 . The four corners of the mounting bracket are respectively connected with one end of the slanting brace 8 by pins, and the other end of the slanting brace is connected with the convex plate 12 on the upper welding box type by pins. The four corners of the upper welding box bottom are provided with the pulley frame 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com