Serial two-way throttling stub pipe mechanism and throttling method thereof

A short-throttle tube and two-way throttling technology, which is applied to refrigerators, mechanical equipment, fluid circulation arrangements, etc., can solve the problems of increasing production costs, increasing the probability of welding joint leakage, one-way valve noise, etc., and reducing welding joints , remarkable technical effect and application value, and the effect of avoiding vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

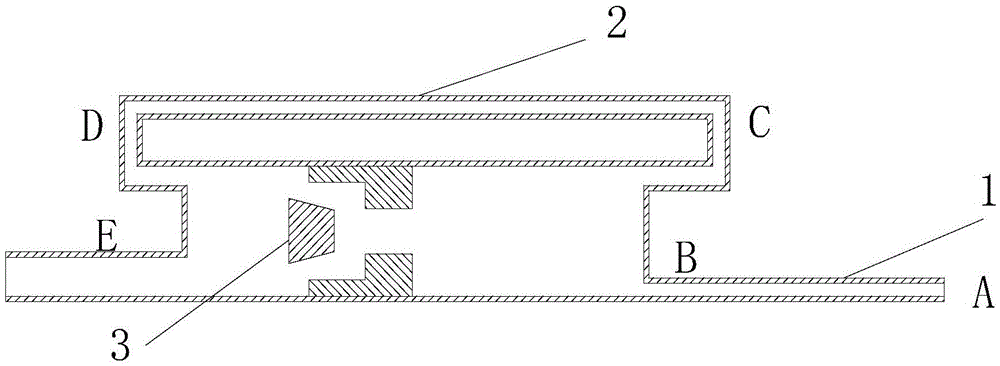

[0031] figure 1 It is a structural schematic diagram of the prior art.

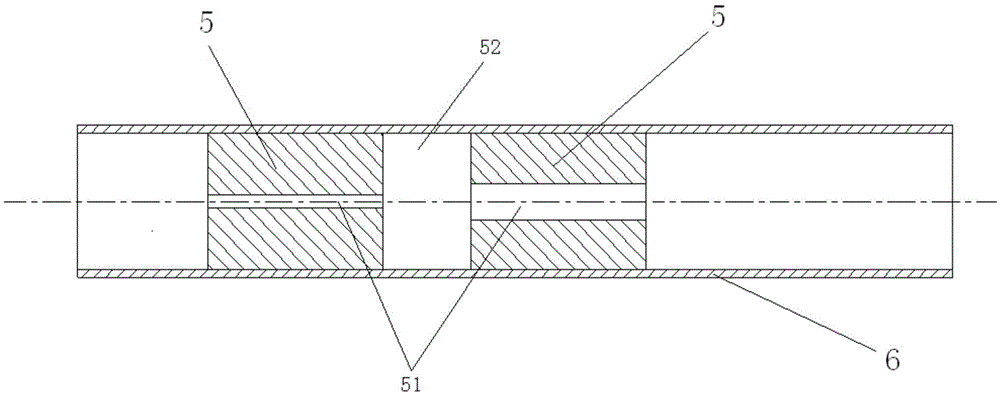

[0032] figure 2 It is a structural schematic diagram of the serial bidirectional throttle short tube mechanism of the present invention. The present invention includes a metal pipe 6, and a multi-stage throttling spool spool 5 axially arranged in the metal pipe 6 at intervals; the space between each section of the choke short pipe spool 5 forms a flash gas-liquid chamber 52 ;

[0033] The axes of the refrigerant passages 51 of each throttle short tube spool 5 are coaxial with the axes of the metal pipe 6;

[0034] The inner diameter of the refrigerant flow channel 51 from the throttle short tube spool 5 at the initial end to the throttle short tube 51 at the end gradually increases;

[0035] When the air-conditioning system is cooling, the refrigerant enters from the throttle short tube spool 5 at the initial end, and then flows out from the throttle short tube spool 5 at the end;

[0036] When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com