All-steel out-of-roundness rim replacement tool

A rim and roundness technology, which is applied in the field of all-steel out-of-round rim replacement tooling, can solve the problems of high labor intensity, inconvenient replacement, heavy rim, etc., and achieve the effect of reducing labor efficiency and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

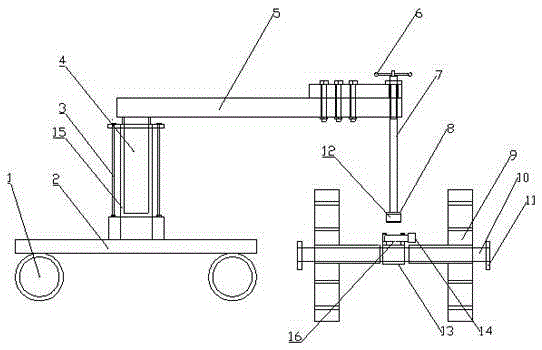

[0018] Such as figure 1 Shown is an all-steel out-of-round rim replacement tool, which is used to replace rims of different specifications, including a base, a moving mechanism, a support bracket and a loading mechanism.

[0019] The base includes a fixed base 2, a support base 3 is installed on the upper end of the fix base 2, and a cylindrical movable cavity 15 extending toward the inside of the support base 3 is provided on the support base 3.

[0020] The moving mechanism comprises a moving roller 1, and there are four moving rollers 1, which are rectangular and installed on the bottom of the fixed seat 2 respectively, and can drive the whole base to move.

[0021] The moving mechanism is also equipped with guide rails used in conjunction with the moving rollers 1, thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com