A vertical submersible motor performance test platform

A submersible motor and test platform technology, applied in measuring devices, power metering, instruments, etc., can solve problems such as difficulty in accurately measuring liquid flow and lift, inability to adjust motor operating points at will, and inability to accurately evaluate motor performance, etc. Liquid nitrogen leakage and sealing problems, reducing resource waste and safety hazards, and comprehensive performance testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

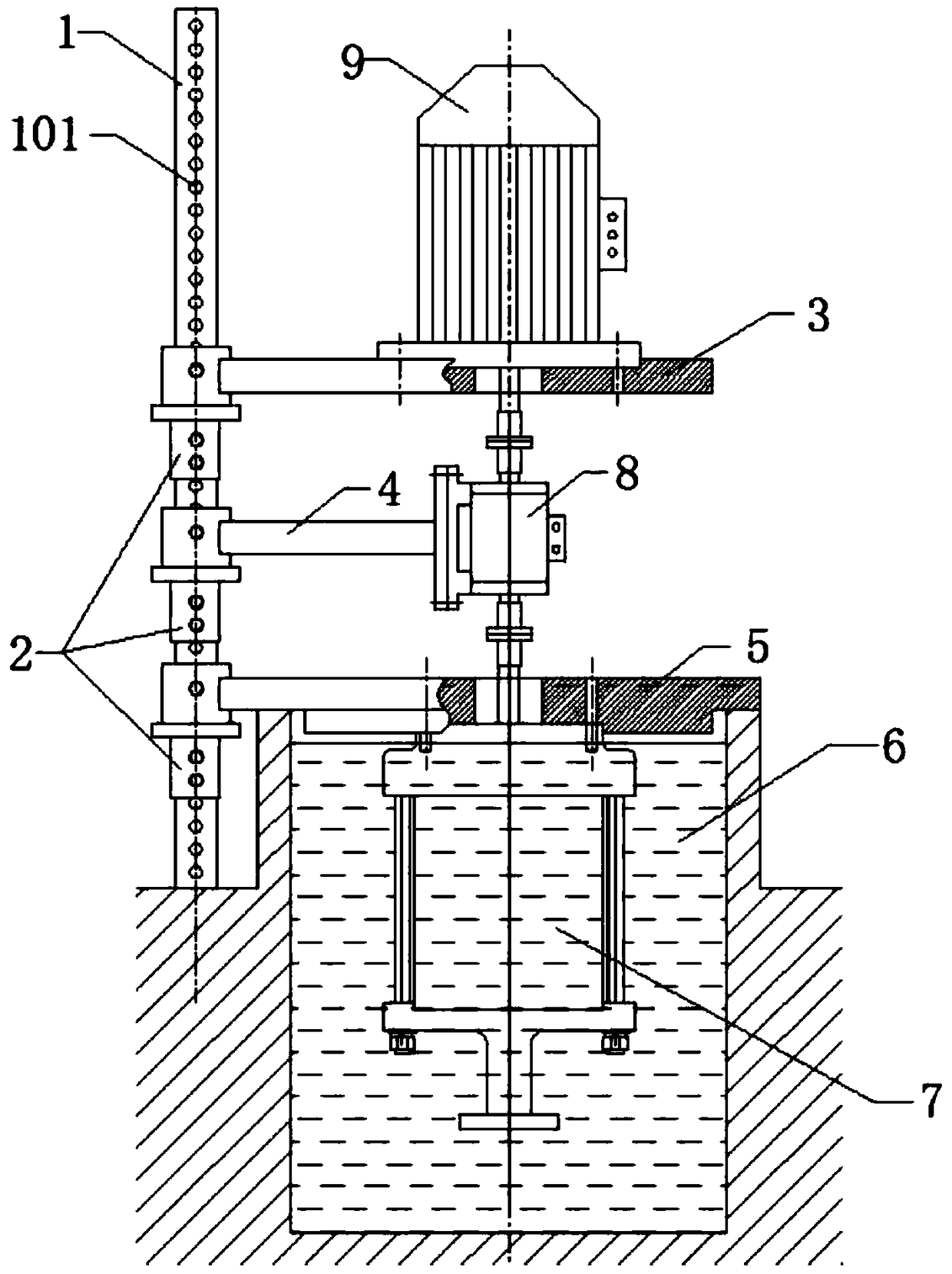

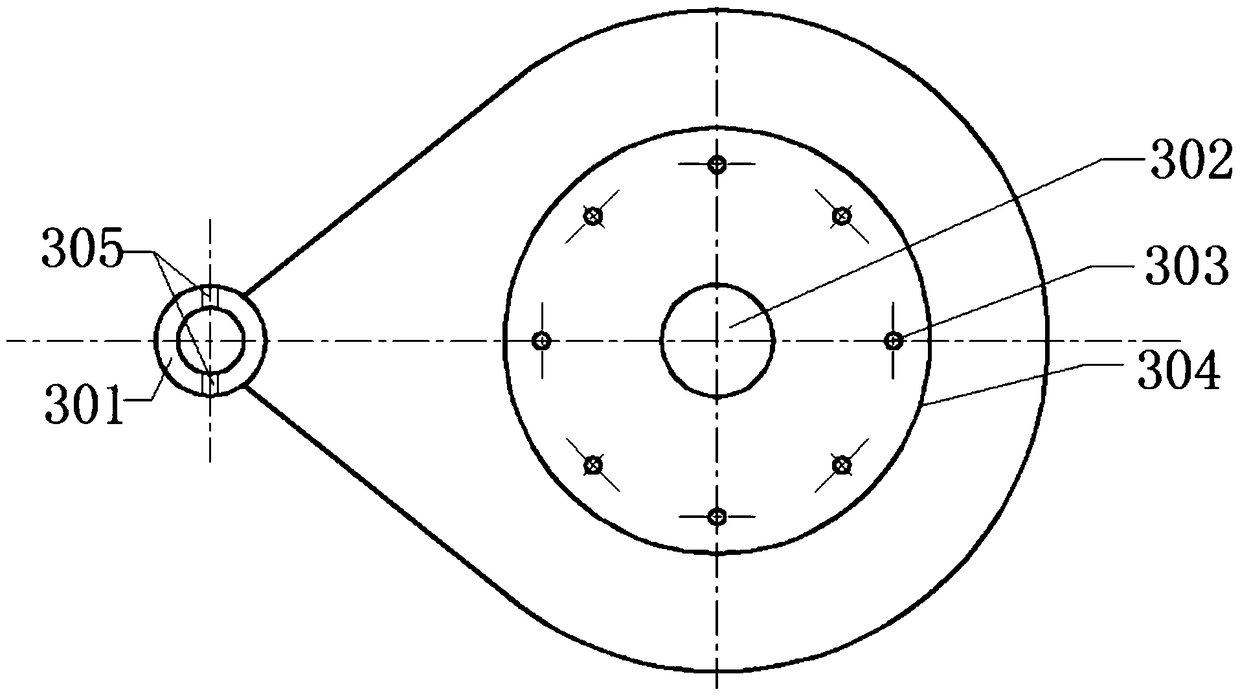

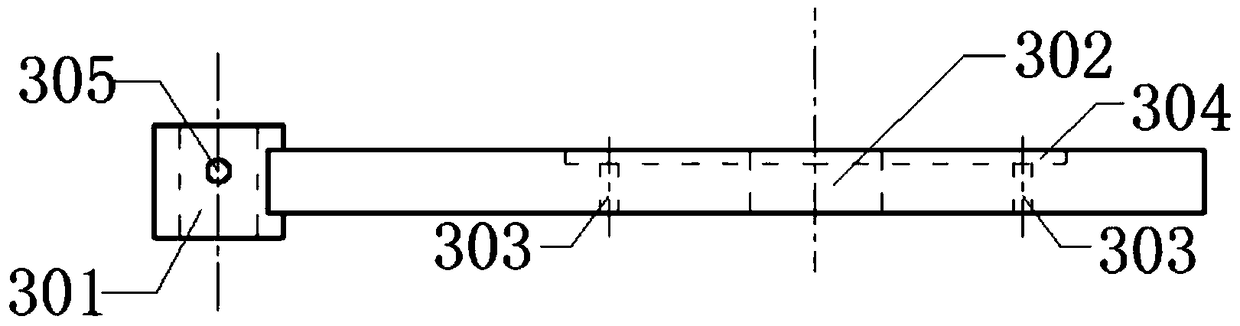

[0043] Such as Figure 1 to Figure 9 As shown, the present invention includes a supporting column 1, a load motor mounting plate 3, a tester mounting plate 4, a tested motor mounting plate 5 and a liquid nitrogen pool 6, and the supporting column 1 is fixed on one side of the liquid nitrogen pool 6 , the load motor mounting plate 3, the tester mounting plate 4, and the tested motor mounting plate 5 are sequentially fixed on the support column 1 from top to bottom.

[0044] It also includes three support positioning parts 2, the support positioning parts 2 are installed on the support column 1, and are respectively located under the load motor mounting plate 3, the tester mounting plate 4 and the tested motor mounting plate 5.

[0045] The support column 1 is a solid cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com