A Calcined Coke Shock Density Tester

It is a technology of tapped density and tester, which is applied in the direction of instruments, measuring devices, scientific instruments, etc. It can solve the problems of damaged measuring cylinder, inconvenience, uncontrollable clamping force, etc., and achieves convenient clamping and taking, convenient use and high performance. reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

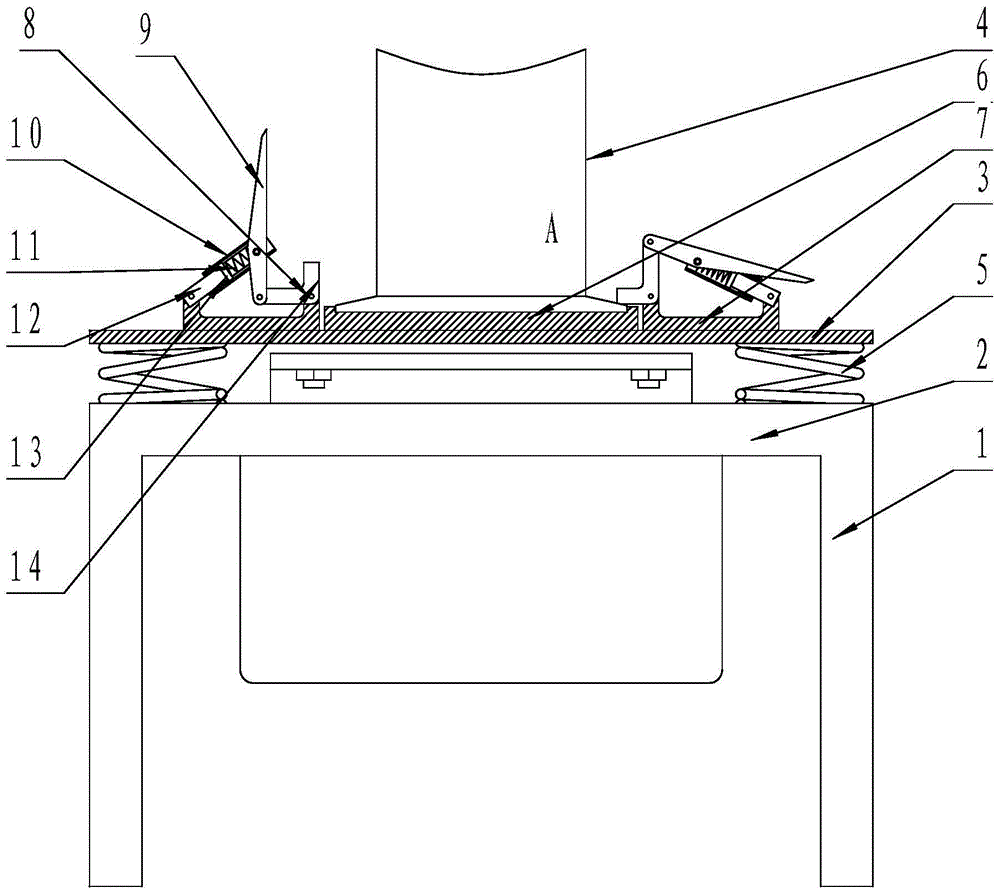

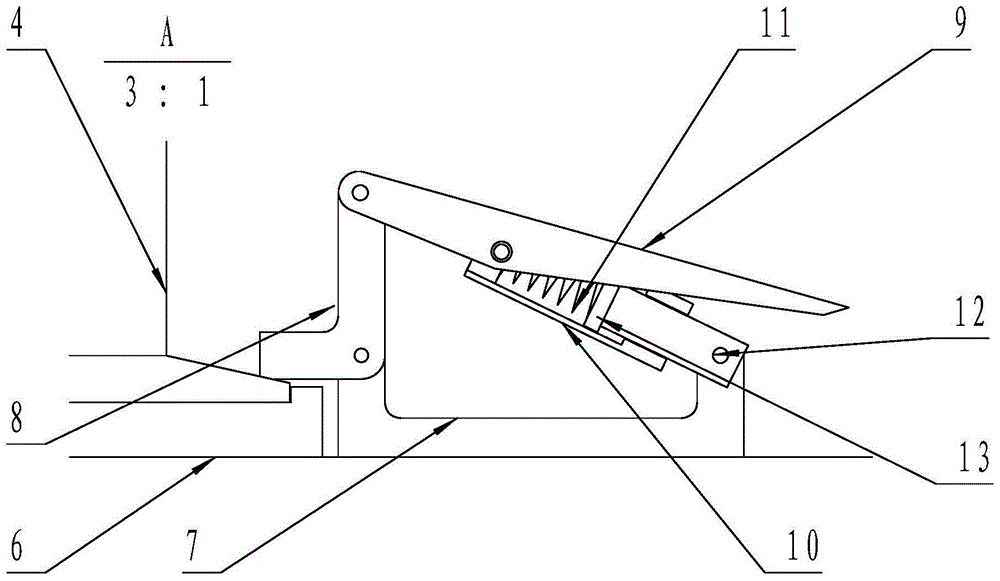

[0016] Such as figure 1 , figure 2 As shown, a calcined coke compact density tester includes a support 1, a workbench 2 installed on the support 1, a calcined coke compact density tester installation platform 3, and a measuring cylinder 4. The bottom of the measuring cylinder 4 has feet extending outward , which is characterized in that: the workbench 2 is installed with a shock-absorbing installation platform for a calcined coke solid density tester, and the shock-absorbing installation platform for a calcined coke solid density tester includes two respectively installed on both sides of the top surface of the workbench 2 A set of shock absorbing springs 5, the two sets of shock absorbing springs 5 installed on both sides of the top surface of the workbench 2 are installed on the top of the calcined coke compact density tester installation platform 3; the calcined coke compact density tester installation platform 3 A measuring cylinder mounting base 6 is installed at the ...

Embodiment 2

[0018] Such as figure 1 , figure 2 As shown, a calcined coke compact density tester includes a support 1, a workbench 2 installed on the support 1, a calcined coke compact density tester installation platform 3, and a measuring cylinder 4. The bottom of the measuring cylinder 4 has feet extending outward , which is characterized in that: the workbench 2 is installed with a shock-absorbing installation platform for a calcined coke solid density tester, and the shock-absorbing installation platform for a calcined coke solid density tester includes two respectively installed on both sides of the top surface of the workbench 2 A set of shock absorbing springs 5, the two sets of shock absorbing springs 5 installed on both sides of the top surface of the workbench 2 are installed on the top of the calcined coke compact density tester installation platform 3; the calcined coke compact density tester installation platform 3 A measuring cylinder installation base 6 is installed at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com