Battery module supporting frame and battery module

A battery module and support frame technology, which is applied in the direction of battery pack parts, circuits, electrical components, etc., can solve the problems of complex connection, damage to the battery pack, troublesome assembly, etc., and achieve simple assembly process, firm structure, and convenient connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

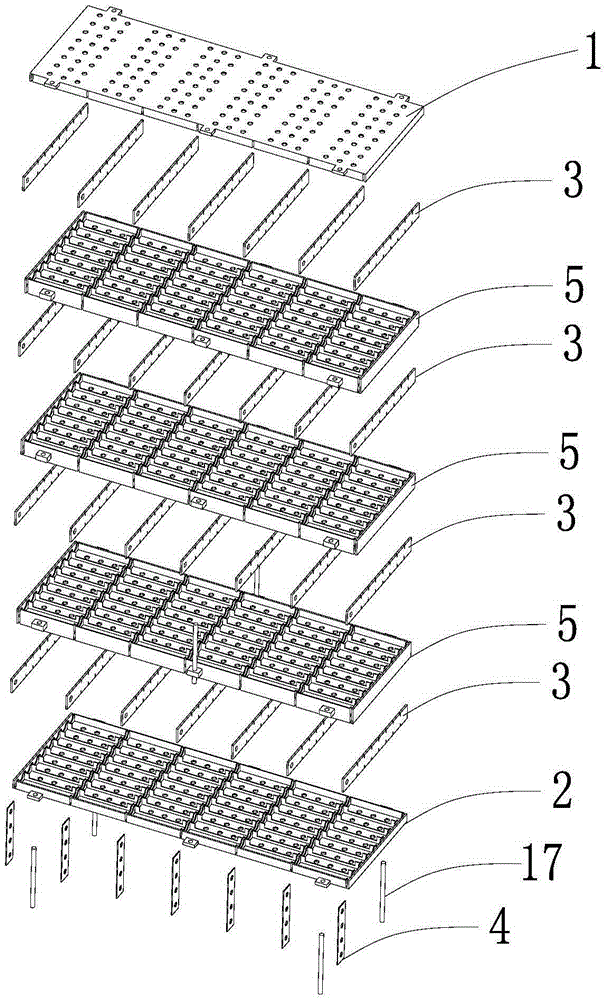

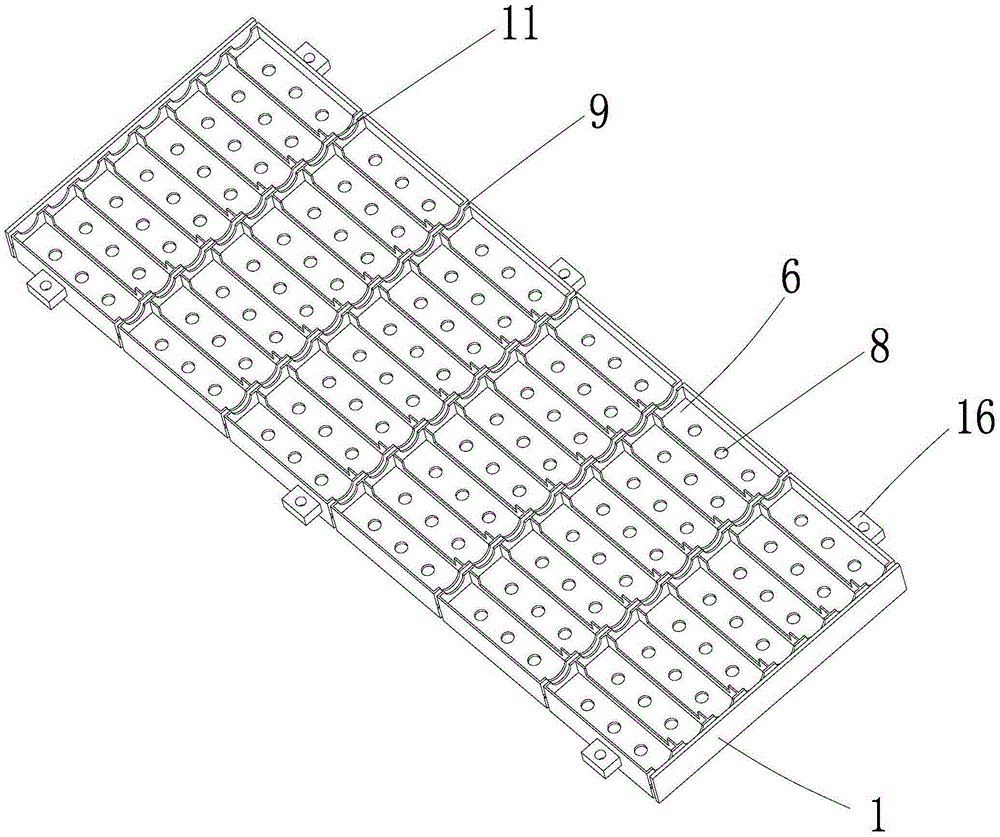

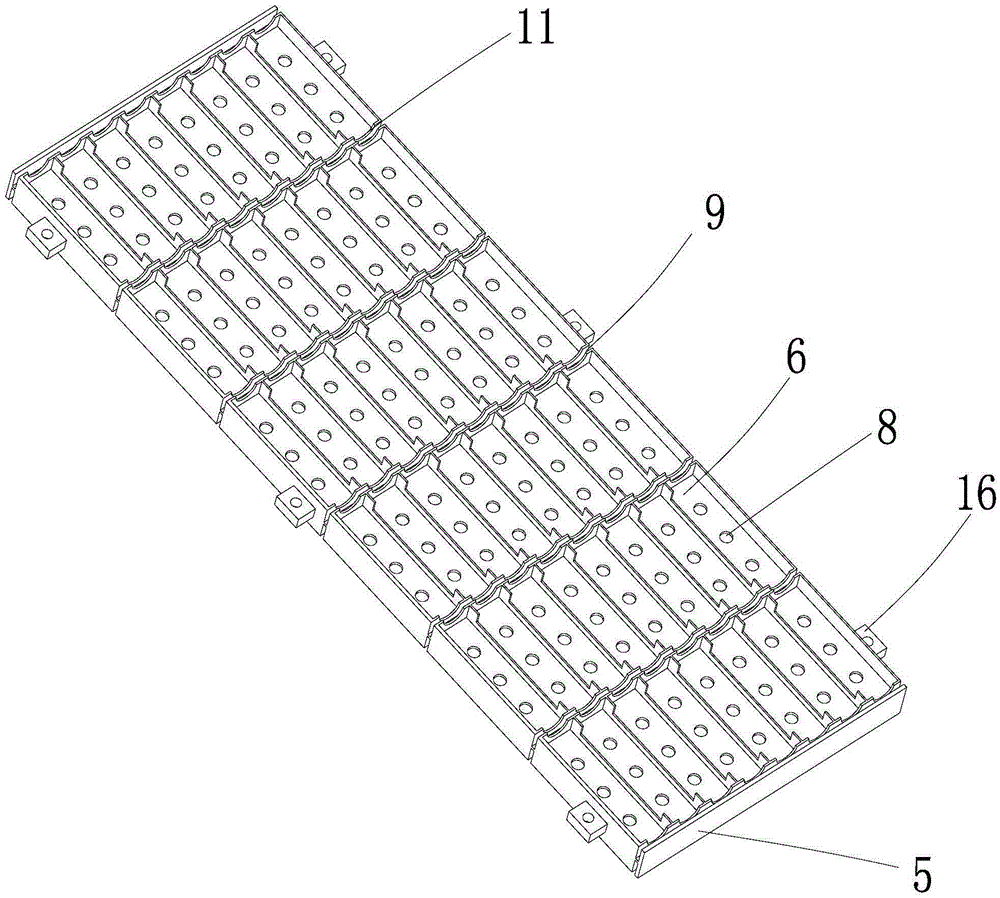

[0032] Such as Figure 1-5 As shown, a battery module support frame includes an insulating upper bracket 1, an insulating lower bracket 2, a first electrical connector 3, a second electrical connector 4 and an insulating intermediate bracket 5. In this embodiment, the intermediate bracket The number of 5 is 3, which are stacked between the upper bracket 1 and the lower bracket 2 in sequence. The upper bracket 1 is provided with several rows of battery storage slots 6, and each row of battery storage slots 6 is provided with several battery storage slots 6 side by side. In this embodiment, the upper support 1 is provided with six rows of battery accommodation grooves 6, and each row of battery accommodation grooves 6 has eight battery accommodation grooves 6. Of course, in other embodiments, the middle bracket 5 and the row of battery accommodation grooves 6 The number and the number of battery accommodating slots 6 in each row can be set according to actual needs. The width o...

Embodiment 2

[0041] The difference between this embodiment and Embodiment 1 is that there is no intermediate support 5 and second electrical connector 4 , that is, there is only one layer of batteries 7 .

[0042] The assembly process of the battery module of this embodiment is as follows:

[0043] First place the lower bracket 2, and then place a first electrical connector 3 in each first electrical connector receiving groove 9 on the lower bracket 2, and make the shrapnel or spring 12 on the first electrical connector 3 face the same direction when placing , the first through holes 14 of the first electrical connector 3 are all facing the same side direction of the bracket; The elastic piece 12 is in contact, and the positive pole is in contact with the side of the first electrical connector 3 without the spring or the elastic piece 12 through the opening 11 of the side wall of the first electrical connector receiving groove 9, so that the battery is installed; The battery accommodating...

Embodiment 3

[0045] Such as Figure 9 As shown, the difference between this embodiment and the first embodiment is that two first electrical connectors 3 are placed in each complete first electrical connector receiving groove, and these two first electrical connectors 3 are placed on the left and right for The parallel connection of the same row of batteries 7 turns the same row of batteries 7 into two parallel parts, and further turns the same layer of batteries into two series-parallel parts, and then connects the two series-parallel parts in series.

[0046] The assembly process of this embodiment is similar to that of Embodiment 1. First, the lower bracket 2 is placed, but a first electrical connector 3 is placed on the left and right in each first electrical connector receiving groove 9 of the lower bracket 2, and when placed, the left Part of the elastic piece or spring 12 on the first electrical connector 3 faces the same direction, the elastic piece or spring 12 on the right part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com