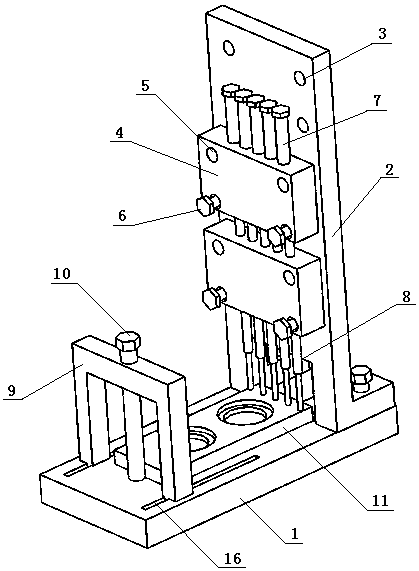

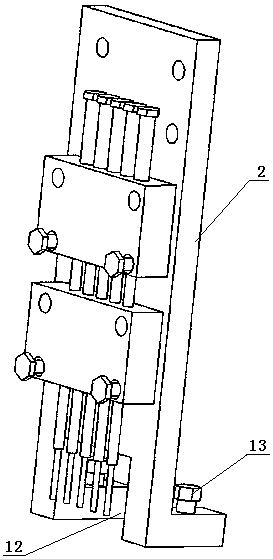

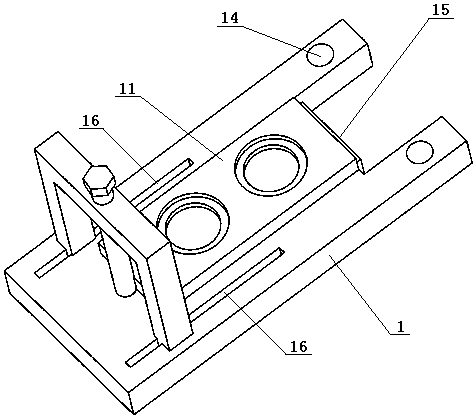

A high-power laser bar chip sintering fixture

A technology of high-power lasers and fixtures, applied in lasers, laser components, semiconductor lasers, etc., can solve the problem of double beam quality reduction, affecting semiconductor laser beam propagation, focusing, shaping, and increasing off-axis images of fast-axis collimator mirrors Poor and other problems, to achieve the effect of correcting bending, improving production efficiency, and ensuring beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] The present invention needs to apply according to the actual bending situation: the pressure gradually decreases from the middle to both ends of the chip; it includes 5 spring probes, and the pressure of each spring probe can apply different pressures by changing different lengths. Among them, the pressure of the middle spring probe is 2N, the pressure of the spring probe next to the middle spring probe is 1N, and the pressure of the edge spring probe is 0.5N. Through different pressures of spring probes, different pressures are applied to different parts of the chip to achieve smile optimization, which reduces the bending value of 3-4um produced by the previous smile effect to 1.5um, improves the beam quality of the chip, and greatly improves the semiconductor laser beam Spread, focus, shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com