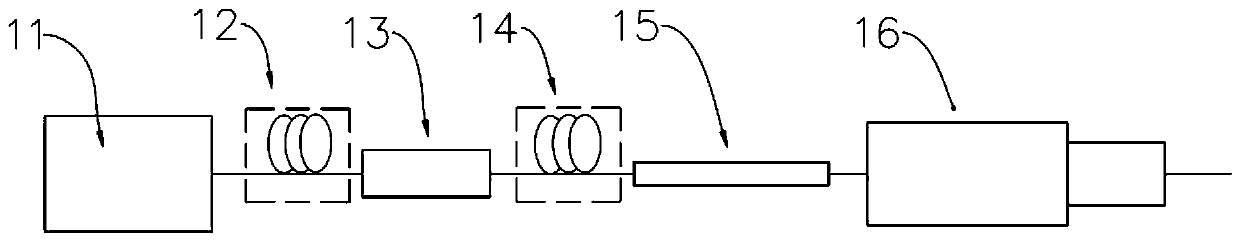

Collimator and laser

A collimator and fiber optic component technology, applied in the field of collimators and lasers, can solve problems such as laser spectrum drift, damage to the laser system, unstable output power, etc., and achieve the effect of reducing costs and saving layout space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

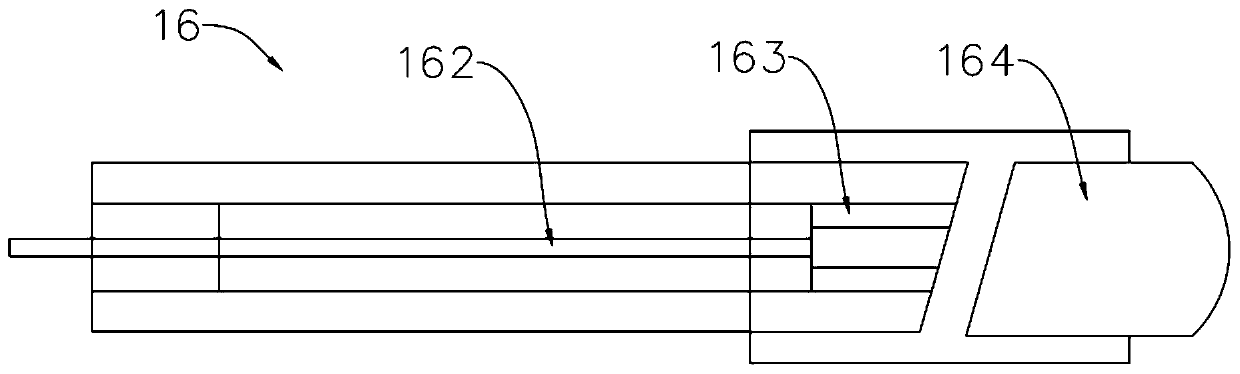

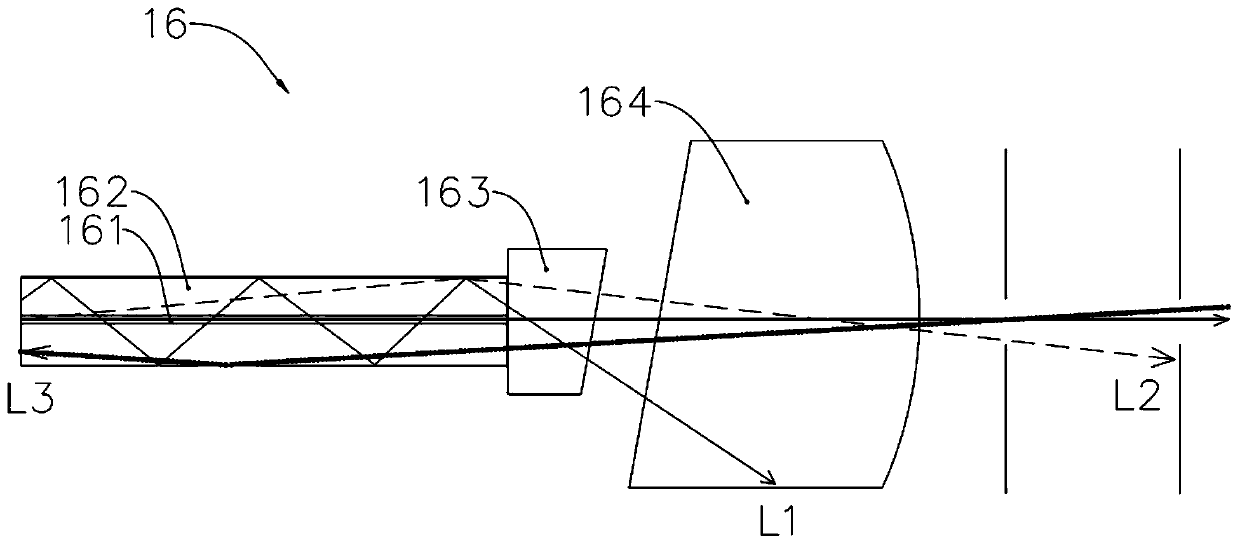

[0027] refer to Figure 4 to Figure 5 , the collimator 3 includes an optical fiber assembly, an end cap 33, an output lens 34 and a sleeve 38, the optical fiber assembly includes a core 31 and a cladding assembly 32, the core 31 is located in the cladding assembly 32, and the outer surface of the cladding assembly 32 A functional ring groove 321 is provided, and the functional ring groove 321 extends along the circumferential direction of the fiber core 31. The functional ring groove 321 is sunken from the outer surface of the cladding component 32 toward the fiber core 31. The functional ring groove 321 is provided with a bottom wall 322 and is located at The side walls 323 at both ends of the axial direction, the bottom wall 322 of the functional ring groove 321 is parallel to the axial direction of the fiber core 31, and the two side walls 321 are respectively located at the two axial ends of the bottom wall 322 of the fiber core 31, and the two side walls 321 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com