A novel microwave probe contact sheet and its manufacturing method

A manufacturing method and a technology of a contact sheet, which are applied in the field of microwave probes, can solve the problems of difficult removal of the contact surface, high processing difficulty, and high processing cost, and achieve the effects of reducing sliding friction, reducing processing difficulty, and reducing processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

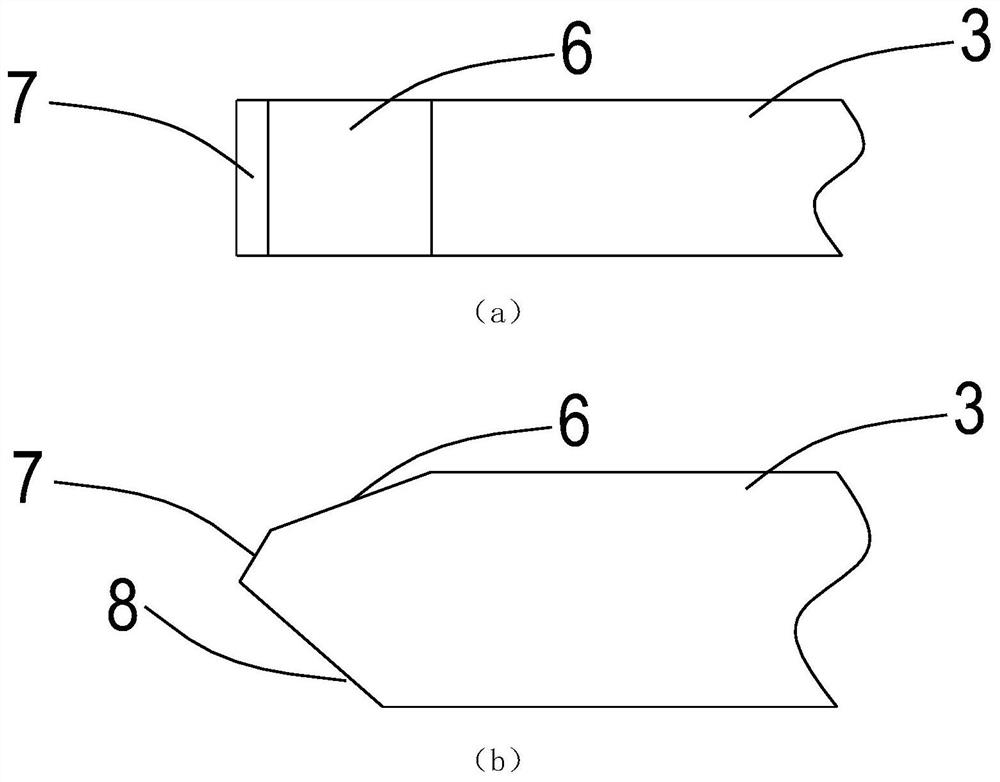

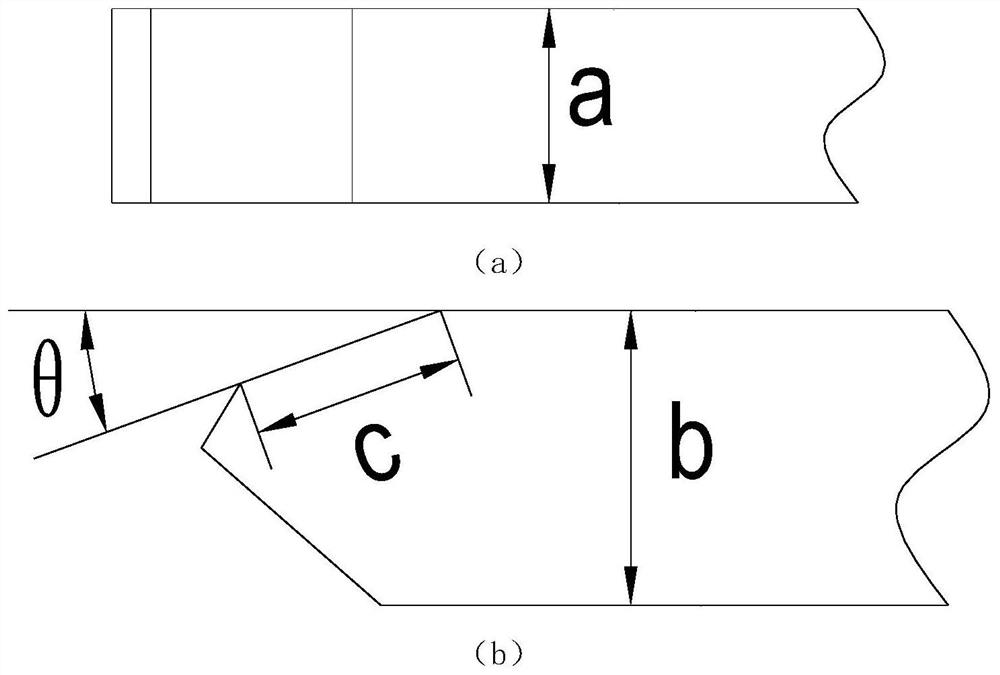

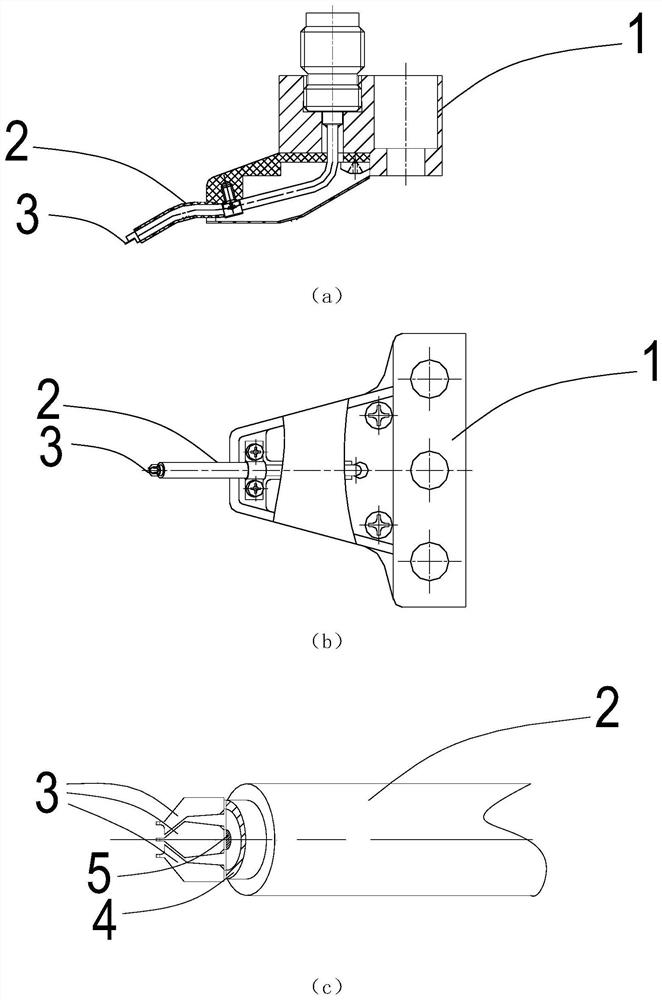

[0049] The invention provides a novel microwave probe contact piece, which comprises a plurality of parallel contact pieces arranged at the front end of the coaxial cable. The bottom surface of the front end of each contact piece is an elliptical arc surface, and the top surface of the front end is Inwardly concave bevel. Taking a certain type of GSG microwave probe as an example, the technical solution of the present invention is described, and its structural diagram is as follows image 3 a and image 3 As shown in b, the probe consists of a base 1, a coaxial cable 2 and a contact piece 3. Among them, the G terminal of the contact piece is assembled on the outer conductor 4 of the coaxial cable, and the S terminal is assembled on the inner conductor 5 of the coaxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com