Carbon-thermal rail

A technology of carbon hot rail and carbon rod, which is applied in the application field of indoor heating technology, can solve the problems existing in the lower layer, heat up and cool down, uneven temperature distribution, etc., and achieve the effect of energy saving and simple laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] A detailed description will be given below in conjunction with the accompanying drawings.

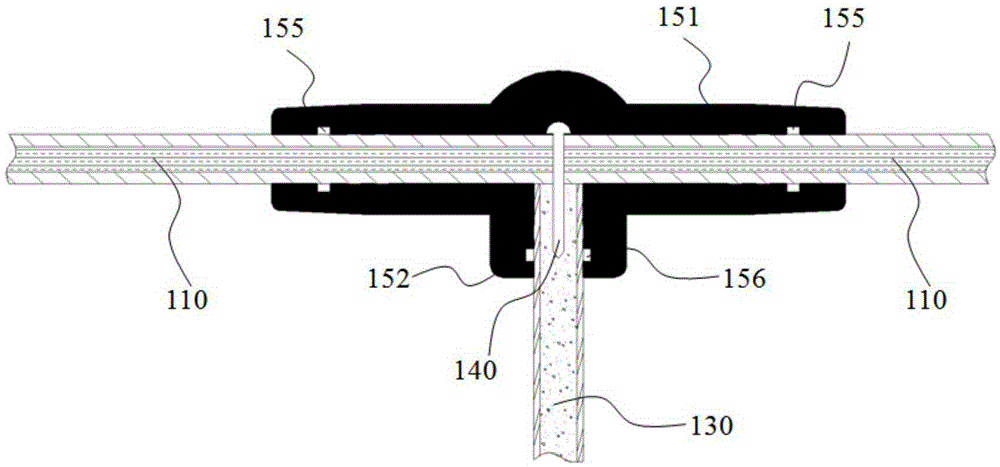

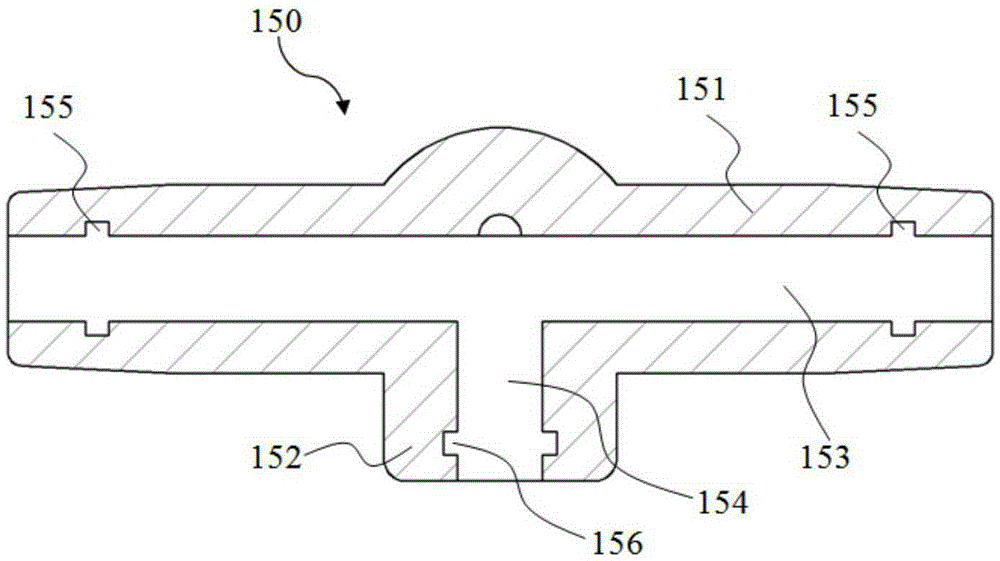

[0045] Such as Figure 1~3 As shown, it shows a preferred embodiment of the present invention.

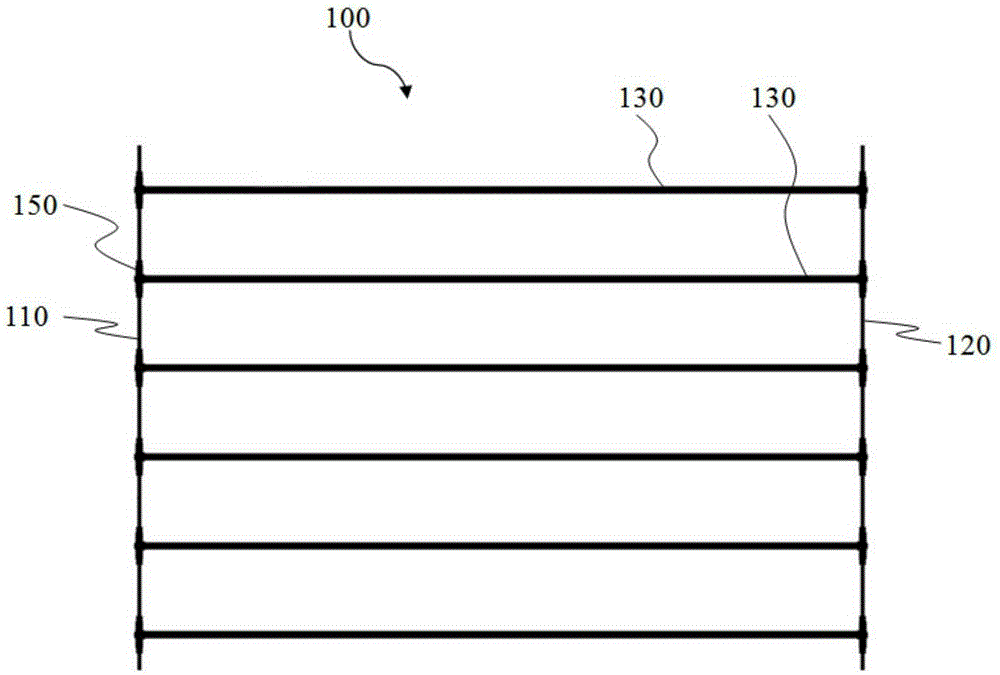

[0046] A carbon thermal rail 100 includes a first power line 110 , a second power line 120 arranged parallel to each other, and a plurality of carbon rods 130 arranged between the first power line 110 and the second power line 120 and parallel to each other. Wherein, the carbon rod 130 and the first power line 110 may be arranged perpendicular to each other, or an included angle may be formed between the carbon rod 130 and the first power line 110 . Preferably, the included angle ranges from 30° to 60°. Wherein, the distance between two adjacent carbon rods 130 is 10-500 mm, preferably 100 mm. Wherein, the carbon rod 130 is an oval strip with a length of 800-1000 mm, preferably 820 mm.

[0047] Two ends of the carbon rod 130 are respectively electrically connected to the first pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com