A noodle machine that is easy to install and disassemble

The technology of a noodle machine and a machine body is applied in the direction of a dough extruder, etc., which can solve the problems of not having a good fixing effect, shaking of the fabric barrel, troublesome operation, etc., and achieve the effects of simple structure, stable structure and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

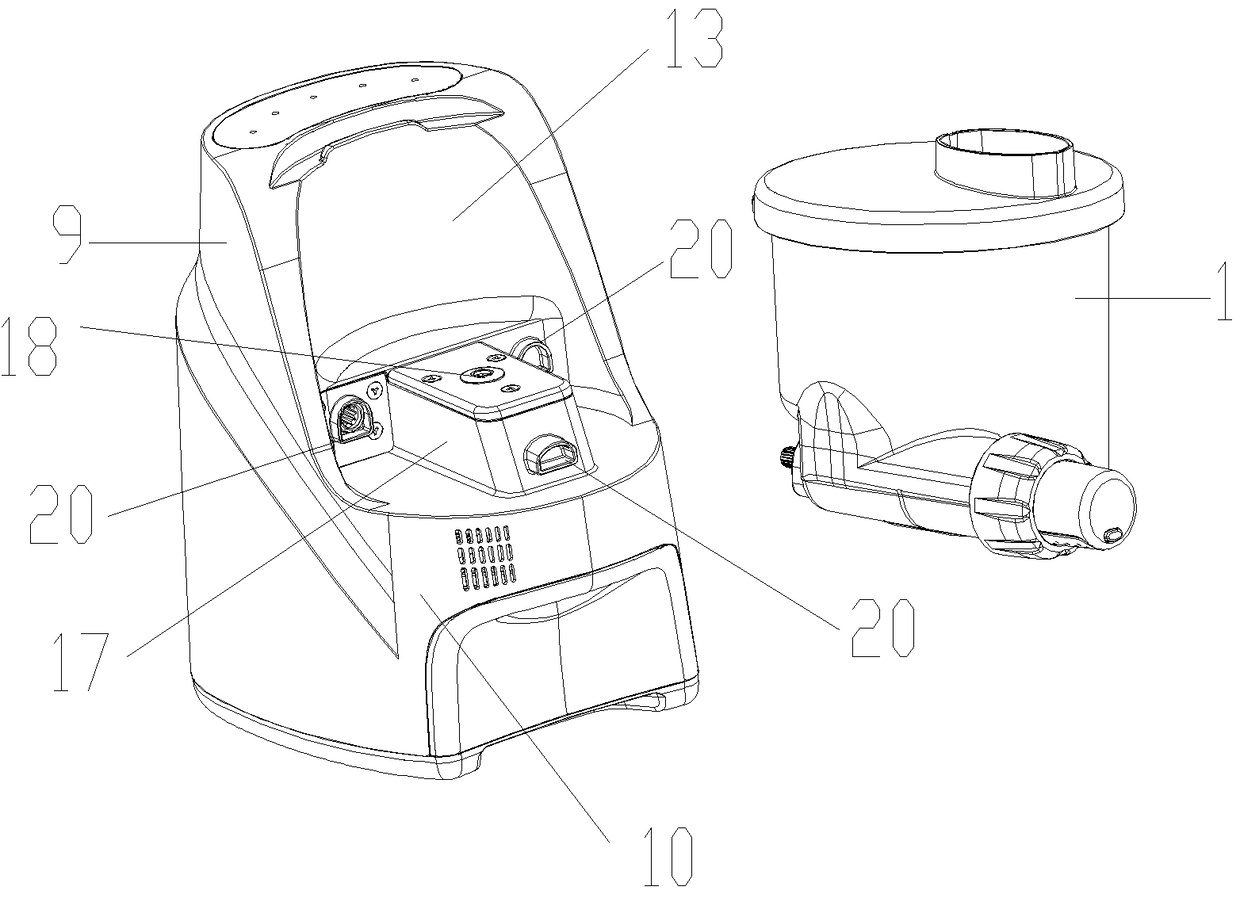

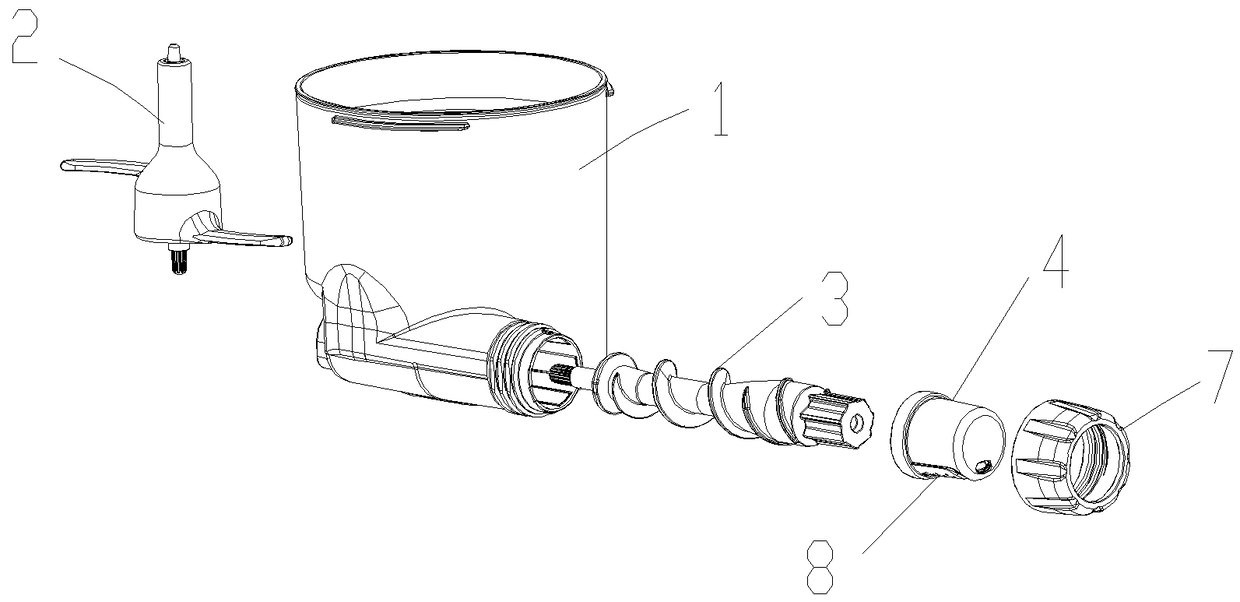

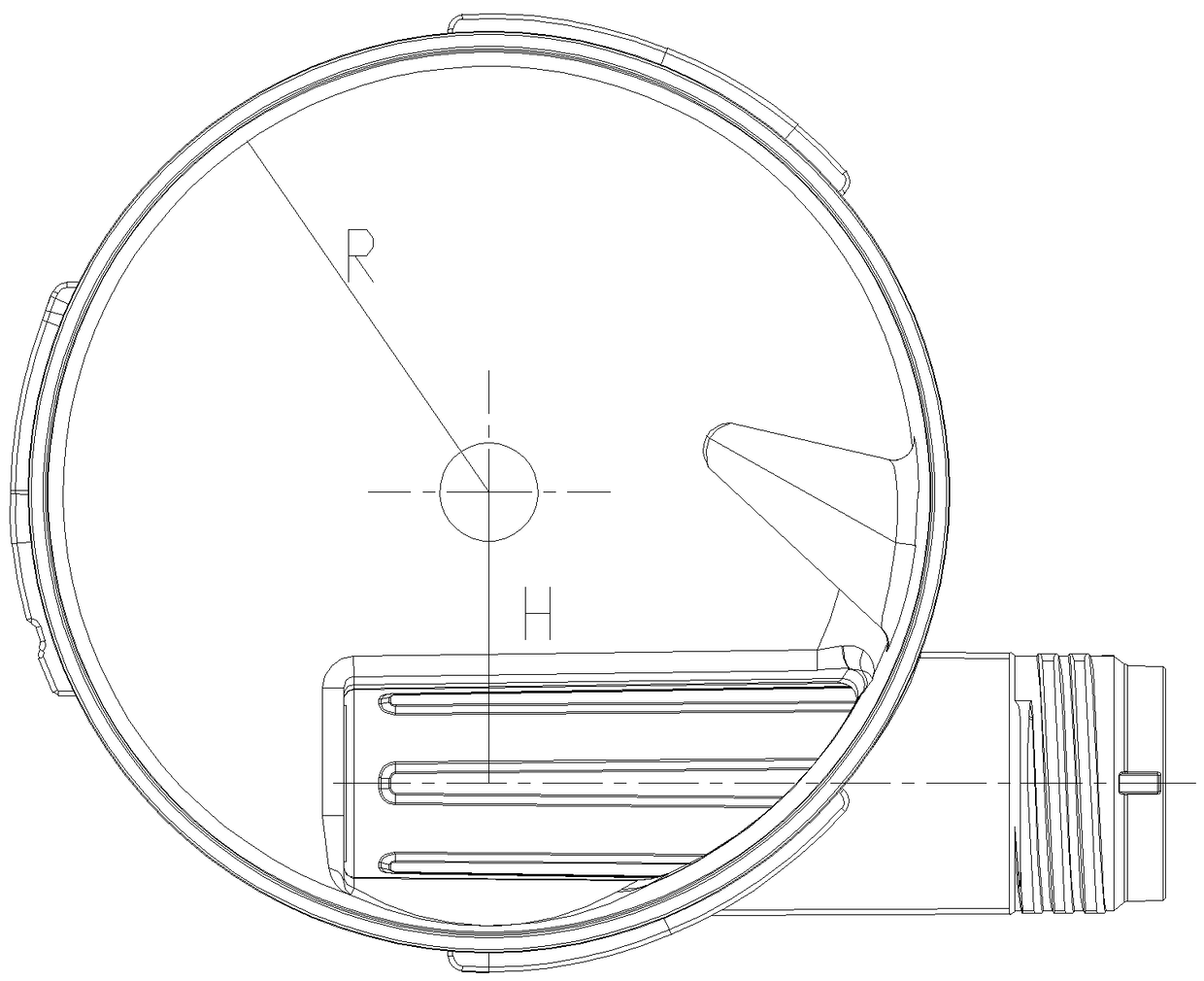

[0033] Such as figure 1 , figure 2 As shown, a noodle maker that is easy to install and disassemble includes a host with a motor, a stirring assembly, and an extrusion assembly. The stirring assembly includes a stirring cup 1 and a stirring rod 2. The stirring cup 1 includes a cup body and a cup cover, The extrusion assembly includes a screw 3, a die 4, and a dough extruder 5. The dough extruder 5 is placed on the lower side of the mixing cup 1, and the mixing cup 1 passes through the noodle inlet 6 and The noodle extrusion cylinder 5 is connected, the noodle inlet 6 is arranged at the bottom of the mixing cup 1 and is arranged along the tangential direction of the connection between the bottom of the mixing cup 1 and the side wall, and the die 4 is installed by a locking member 7 Set at the end of the noodle extrusion cylinder 5, the locking member 7 is screwed and fixed with the noodle extrusion cylinder 5, and the die 4 is provided with a molding hole 8 which is vertically d...

Embodiment 2

[0045] Such as Figure 7 As shown, the difference between this embodiment and embodiment 1 is that the noodle squeezing cylinder 5 is lying on the lower side of the mixing cup 1, and a recessed area 23 is formed on the base 10, and the recess The area 23 just accommodates the dough extruder 5, the length of the recessed area 23 is smaller than the length of the dough extruder 5, the depth of the recessed area 23 is consistent with the height of the noodle extruder 5, so that When the dough cylinder 5 is installed in the recessed area 23, the bottom wall of the mixing cup 1 is just next to the base 10, and the end of the recessed area 23 is provided with a motor drive shaft. The shaft is connected to the screw 3, the side wall of the mixing cup 1 still cooperates with the fuselage 9 to achieve lateral fixation, the bottom wall of the mixing cup 1 is directly attached to the base 10 and fixed by the screw 3 Position, the longitudinal fixation with the base 10 is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com