Ceramic pot and processing process of ceramic pot

A processing technology, a technology for ceramic pots, applied in the field of ceramic pots, can solve the problems of slow heating speed, short service life, easy surface oxidation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

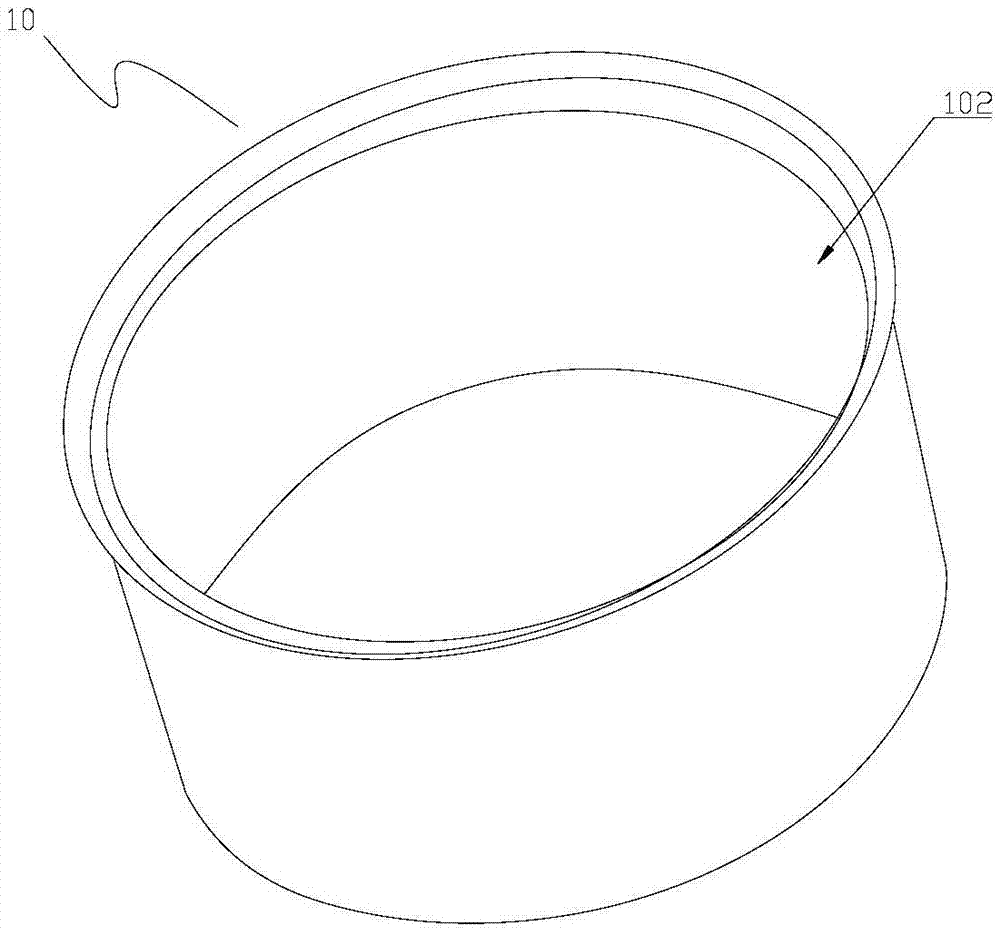

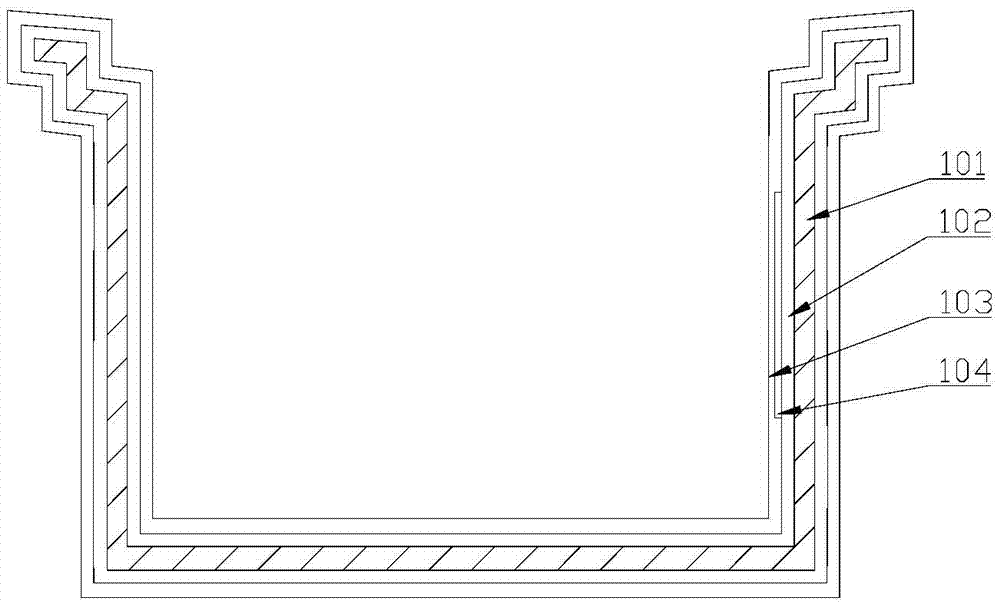

[0032] Such as figure 1 As shown, a ceramic pot 10 includes an inner container 101 made of ceramic material, the surface of the inner container 101 is covered with at least one first non-stick oil layer 102, and the outermost first non-stick oil layer is covered with at least A layer of second non-stick oil layer 103 , the second non-stick oil layer 103 is transparent, and a silk screen pattern 104 is provided on the surface of the first non-stick oil layer 102 adjacent to the second non-stick oil layer 103 . Repeated coating of multiple layers of non-stick oil on the inner tank 101, better non-stick property, easier to clean; and printing the silk screen pattern on the first non-stick oil layer 102, covering the second non-stick oil on the printed pattern, printing The pattern adhesion is better, and it is not easy to fall off.

[0033] Wherein, the liner adopts grouting molding or roll forming, and the surface of the liner can only be provided with one layer of first non-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com