Full-automatic putty powder stirring device and stirring and spraying integrated machine

A stirring device and putty powder technology, applied in mixers with rotating stirring devices, mixers, transportation and packaging, etc., can solve the problems of slow speed, low mixing and spraying efficiency, etc., and achieve fast discharge speed and save stirring Time and feeding time, the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

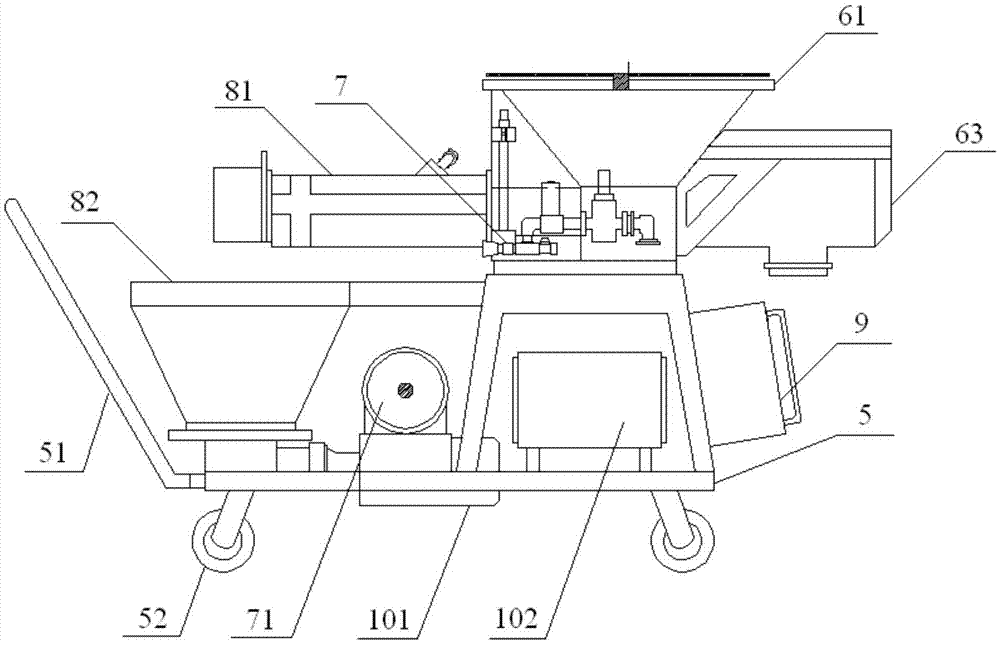

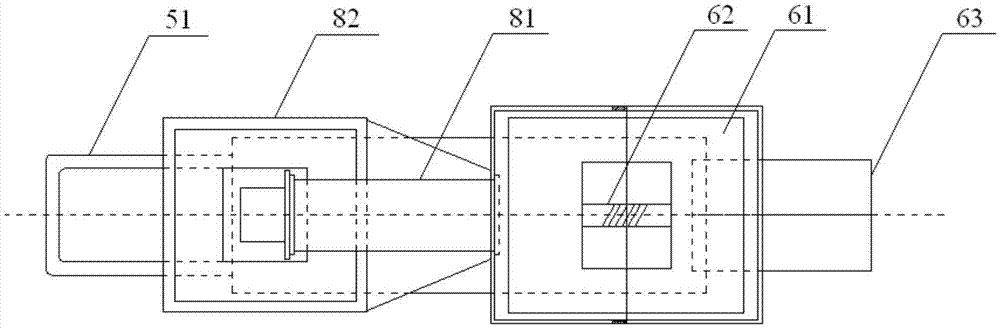

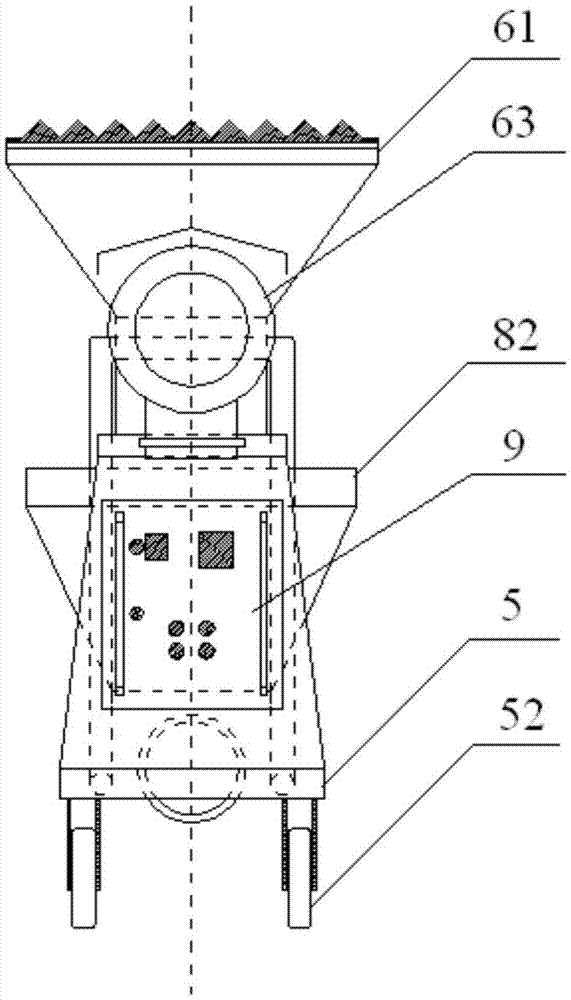

[0037] combine Figure 1 to Figure 7 As shown, the full-automatic putty powder stirring device of the present invention comprises frame 5, feeding system, water supply system 7, stirring system and control system 9, and feeding system includes feeding hopper 61, feeding shaft 62 and stirring motor 63, feeding Shaft 62 is arranged on the bottom of feeding hopper 61, and stirring motor 63 is connected with feeding shaft 62; Water supply system 7 includes water supply pipe (not shown), water pump 71 and solenoid valve (not shown), water pump 71 is connected with water supply pipe, The electromagnetic valve is arranged on the water supply pipe; the mixing system includes a mixing bucket 81, a stirring shaft and a hopper 82, the stirring shaft is arranged in the mixing bucket 81 and is connected with the feeding shaft 62, and the hopper 82 is arranged at the outlet end of the mixing bucket 81, The inlet end of the mixing tank 81 is respectively communicated with the feeding hopper ...

Embodiment 2

[0061] combine Figure 1 to Figure 7 As shown, the fully automatic putty powder mixing and spraying all-in-one machine of the present invention includes a spraying system and the fully automatic putty powder mixing device of Embodiment 1, and the spraying system includes a screw pump (not shown) and a geared motor 101 connected to the screw pump, The screw pump communicates with the discharge hopper 82 , and the geared motor 101 is electrically connected with the control system 9 .

[0062] In the present invention, a spraying system is used to implement spraying. In one embodiment, the spraying system includes a screw pump and a reduction motor 101. The inside of the screw pump is provided with a feeding screw blade, the upper part of the screw pump is connected to the discharge hopper 82, and the front end of the screw pump is provided with a discharge port. The air compressor 102 can be connected through the air pipe, and the air compressor 102 can be pressurized after run...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com