An online detection device for rolling mill roll system stability

A detection device and stability technology, applied in the field of rolling mill roll system stability online detection device, can solve the problems of uncontrollable plate shape, restricted steel plate yield, frequent equipment failures, etc., to eliminate roll system crossover and improve yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

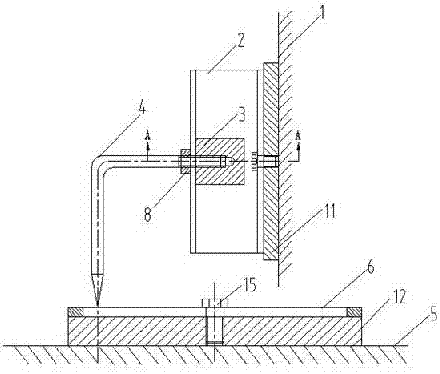

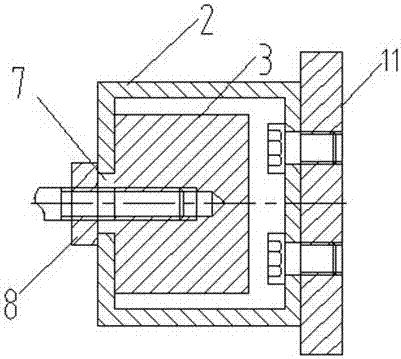

[0019] Figure 1 to Figure 7 It shows that the present invention includes a cylindrical vertical slideway 2, a rectangular connecting plate 11 fixed to the outer surface 1 of the bearing seat and the side surface of the vertical slideway 2 on the upper and lower bottom surfaces respectively, a slider 3 slidingly connected to the vertical slideway 2, The drawing pin 4 bent into a right-angle shape, the drawing board 6, and the upper and lower bottom surfaces are respectively fixed with the plane of the rolling mill archway 5 and the bottom surface of the drawing board 6. , it is provided with the gap 7 that runs up and down on the opposite side of the fixed side of the connecting plate 11; the head of the drawing needle 4 is needle-point-shaped, and the tail is provided with external threads, and its diameter is smaller than the width of the vertical slideway gap 7, so that it can be worn Through the gap 7, the tail of the needle 4 is threaded to the pre-tightening nut 8. The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com