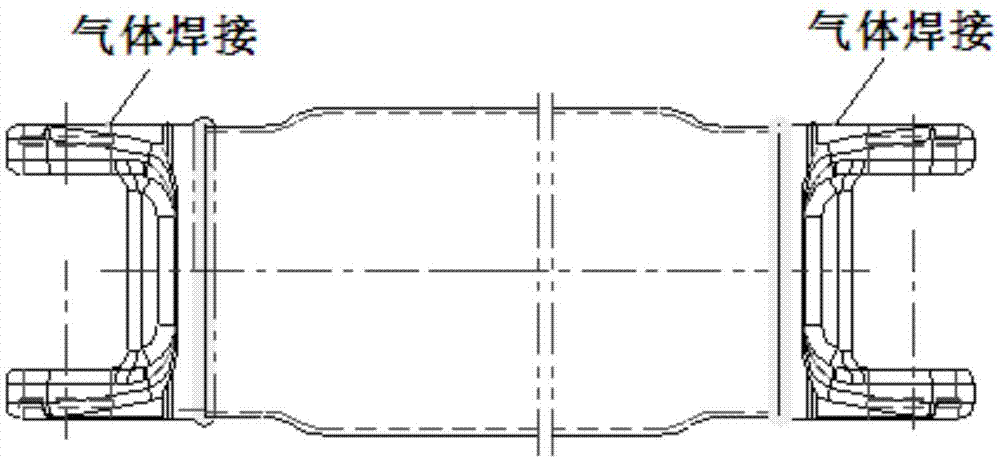

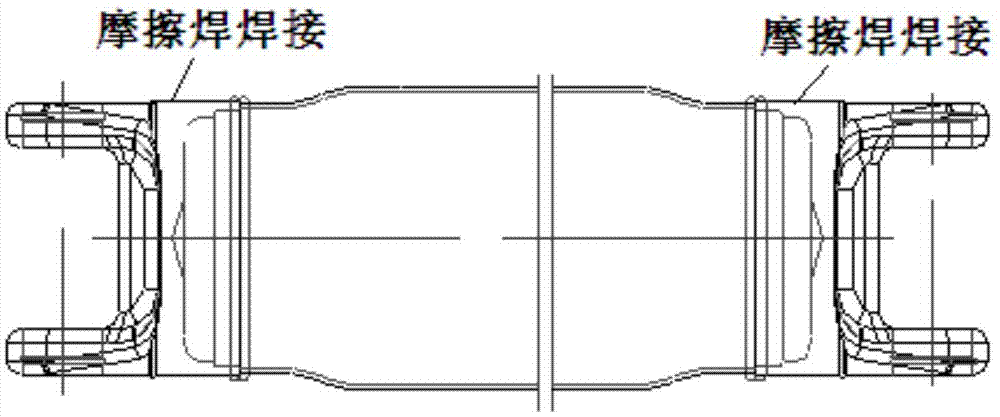

Aluminum alloy friction welding technology

A welding process and friction welding technology, which is applied in the field of aluminum alloy friction welding welding process, can solve problems such as splashing, affecting appearance, environmental pollution, etc., and achieve the effect of dense weld structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in detail below: the friction welding process step of the present invention is as follows:

[0018] 1) Place the two parts on the equipment tooling, and controlled by the computer program, make the welding interface of the two parts contact each other through the servo motor and the main shaft on the equipment tooling, and pass the relative movement under the action of friction pressure Friction is carried out to convert mechanical energy into heat energy;

[0019] 2) Using the high-temperature thermoplastic and friction pressure generated by frictional heat to remove oxides on the welding interface, after a set period of wear or a set length of wear, a certain interface temperature and temperature gradient are reached;

[0020] 3) Braking and applying upsetting pressure and maintaining it for a period of time, welding is carried out under the action of the attractive force between atoms being greater than the repulsive force, and a so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com