A kind of brazing powder and brazing method for ultrasonic assisted brazing

An ultrasonic-assisted, brazing method technology, applied in the direction of welding equipment, welding media, welding/cutting media/materials, etc., can solve the problems of high operation requirements, high welding temperature, low welding efficiency, etc., to reduce gas pollution, joints The effect of high quality and short welding times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0047] (1) The base materials to be brazed are shaped red copper plate 2 and square red copper plate 4, the surface area to be welded of square red copper plate 2 and square red copper plate 4 is smoothed with sandpaper, and then sprayed with alcohol to wash the surface of the area to be welded, and then drying treatment;

[0048] (2) First put the red copper plate 2 and the red copper plate 4 in the groove of the mold, and then place the alloy brazing powder completely wetted with alcohol between the red copper plate 2 and the red copper plate 4.

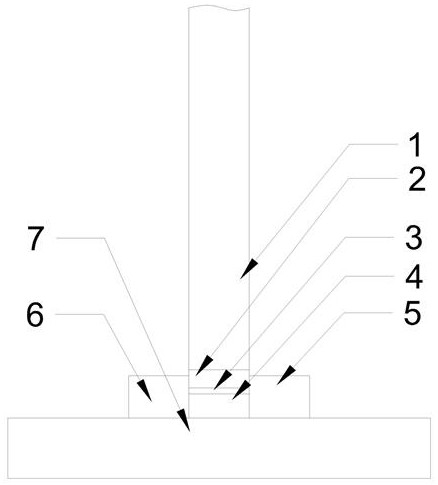

[0049] (3) Use large tweezers to place the specimen placed on the platform 7 with stoppers 5 and 6, and press the longitudinal ultrasonic vibrator 1 of the longitudinal ultrasonic generator on the copper plate 2. The frequency is 50KHz, the power is 2000w, the brazing temperature is room temperature, and the test piece to be welded is ultrasonic-assisted welding, the ultrasonic-assisted welding time is 30s, and the welding time is ...

specific Embodiment 2

[0054] (1) Smooth the surfaces of the square copper plate 2 and the square aluminum alloy plate 4 to be welded with sandpaper, then spray the surfaces of the to-be-welded areas with alcohol, and then dry them;

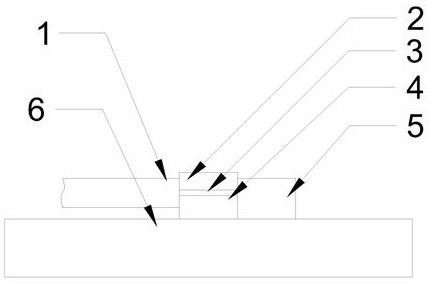

[0055] (2) as figure 2 As shown, the test pieces to be welded are placed in the order of the red copper plate 2 , the intermediate welded body 3 with active nanoparticles, and the aluminum alloy plate 4 .

[0056] (3) Use large tweezers to place the specimen placed on the heating platform 6 with the stopper 5, press the ultrasonic vibrator 1 of the longitudinal ultrasonic generator on the specimen to be welded, and the frequency of the ultrasonic wave of the transverse ultrasonic generator At 20KHz, the power is 100w, the brazing temperature is 230℃, and the test piece to be welded is ultrasonic-assisted welding, the ultrasonic-assisted welding time is 20s, and the welding time is 50s.

[0057] The intermediate welding body with active nanoparticles is preferably Sn0...

specific Embodiment 3

[0061] (1) Polish the surface areas of the square aluminum alloy plate 2 and the square aluminum alloy plate 4 to be welded smooth with sandpaper, then spray the surface of the area to be welded with alcohol, and then dry them;

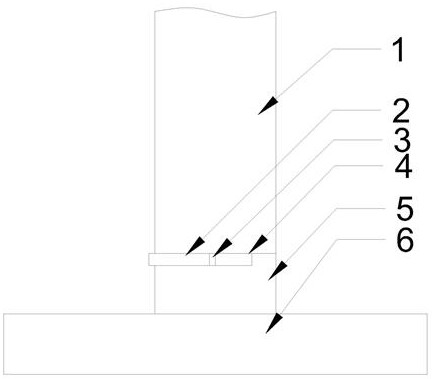

[0062] (2) as image 3 As shown, the test pieces to be welded are placed in the groove of the mold according to the order of the aluminum alloy plate 2, the intermediate welded body 3 with active nanoparticles, and the aluminum alloy plate 4;

[0063] (3) Put the mold with the test piece on the heating platform 6 with large tweezers, and press the ultrasonic vibrator 1 of the longitudinal ultrasonic generator on the test piece to be welded. The ultrasonic frequency of the longitudinal ultrasonic generator is 30KHz and the power is 1500w. , the brazing temperature is 150 ℃, and the specimen to be welded is ultrasonic-assisted welding, the ultrasonic-assisted welding time is 40 s, and the welding time is 100 s.

[0064] The intermediate welding body wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com