Drilling and fixing platform for steel channel of paying-off tackle main frame

A technology for fixing platforms and car owners, applied in clamping, positioning devices, manufacturing tools, etc., can solve the problems of less contact surface of vise, easy deviation of holes, unfavorable machining, etc., to achieve large contact surface of platform and guarantee of product quality. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

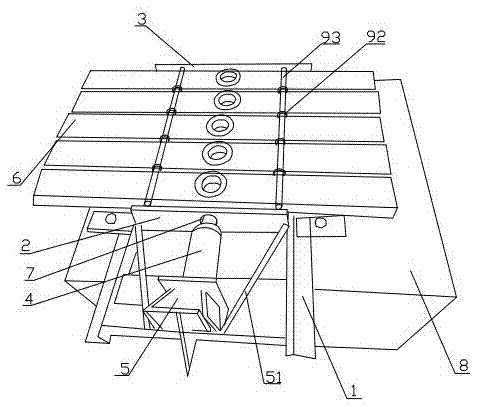

[0020] Such as figure 1 and figure 2 As shown, a channel steel drilling and fixing platform for the main frame of a pay-off block includes two bases 1 arranged in parallel, and a stopper vertically located between the two bases 1 for horizontally accommodating workpieces 6 made of five channel steels. ㄧ2 and head Ⅱ3, the base 1, the head ㄧ2 and the head Ⅱ3 are all made of angle steel, the base 1 can be fixed on a higher position by fastening bolts, such as on the metal platform 8; the outer side of the head ㄧ2 A fixed bracket 5 for placing the jack 4 to clamp the workpiece 6 is provided. The fixed bracket 5 is provided with reinforcing ribs 51 for increasing the bearing pressure. The stopper 2 is provided with a round hole for the top of the jack 4 to pass through 7.

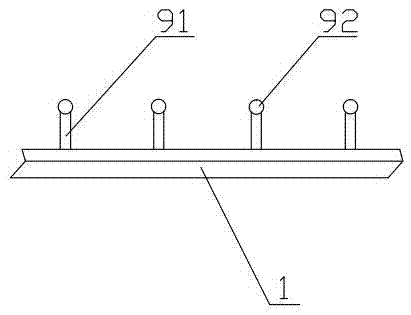

[0021] On the two bases 1, there are symmetrically spaced pressing devices to prevent the movement of the workpiece. The ring 92 and the compression strip 93 passing through all the compression rings 92 on t...

Embodiment 2

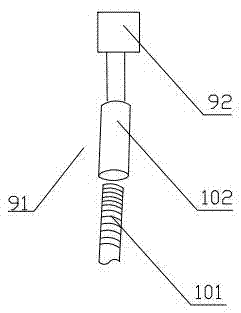

[0025] The difference between this embodiment and embodiment 1 is: see image 3 , the support rod 91 includes a first support rod 101 fixedly connected to the base 1 and a second support rod 102 threaded with the first support rod 101, the second support rod 102 is provided with a rectangular compression ring 92, and the compression bar The section of 93 is also rectangular. The threaded connection can adjust the total length of the first support rod 101 and the second support rod 102, which is convenient to be applied to workpieces 6 of different thicknesses, and has stronger practicability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com