A kind of preparation method of imitation stone composite concrete product

A technology for concrete products and concrete, applied in manufacturing tools, ceramic molding machines, molds, etc., can solve problems such as insufficient hardness, high product cost, and bubbles on the surface, and achieve high product strength, reduced raw material costs, and cost savings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

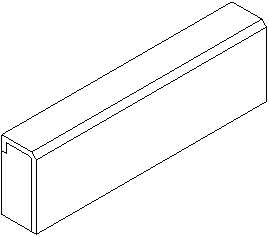

[0081] This embodiment provides a method for preparing a stone-like curb. The curb includes a concrete base and a stone-like surface layer, and at least two faces of the curb are stone-like. In this embodiment, the structure of the curb is as follows figure 1 As shown, it has two imitation stone surfaces, which are mainly used in the middle when laying. The preparation of the curb mainly includes the following steps:

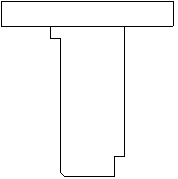

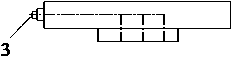

[0082] Step 1: Determine the mold according to the structure of the curbstone to be manufactured and the number of layers of the imitation stone surface. The mold is divided into an upper mold and a lower mold 2; System connection; the upper mold is divided into a surface layer upper mold 101 and a base upper mold 102, the base upper mold is provided with a vacuum drain 3, the vacuum drain 3 is connected to the vacuum drainage system, and the upper mold is placed in a hydraulic device On the upper mold frame, in this embodiment, the structural schematic diagrams...

Embodiment 2

[0100] This embodiment provides a method for preparing a stone-like roadblock ball. The roadblock ball includes a concrete base and a stone-like surface layer, and the other surfaces of the roadblock ball except the bottom surface are stone-like. In this embodiment, the roadblock ball structure Such as Figure 6 As shown, preparing the barricade ball comprises the following steps:

[0101] Step 1: Determine the mold according to the structure of the barricade ball to be manufactured and the number of layers of the imitation stone surface. The mold is divided into an upper mold and a lower mold 2; System connection; the upper mold is divided into a first surface layer upper mold 103, a base body upper mold 102 and a second surface layer upper mold 104, and the second surface layer upper mold 104 is provided with a vacuum drain 3, and a vacuum drain 3 It is connected with the vacuum drainage system, and the upper mold is placed on the upper mold frame of the hydraulic device; Th...

Embodiment 3

[0122] This embodiment provides a method for preparing a stone-like railing post. The railing post includes a concrete base and a stone-like surface layer, and the other surfaces of the railing post except the upper and lower bottom surfaces are stone-like. In this embodiment, the railing post structure Such as Figure 10 As shown, preparing the railing post may include the following steps:

[0123] Step 1: Determine the mold according to the structure of the required railing column and the number of imitation stone surface layers. The mold is divided into an upper mold and a lower mold 2; System connection; the upper mold is divided into a first surface layer upper mold 103, a base body upper mold 102 and a second surface layer upper mold 104, and the second surface layer upper mold 104 is provided with a vacuum drain 3, and a vacuum drain 3 It is connected with the vacuum drainage system, and the upper mold is placed on the upper mold frame of the hydraulic device; The str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com