Roof frame structure with single-layer and double-layer roof combination of two-stage stepper

A technology of secondary step and skeleton structure, applied in the superstructure, superstructure sub-assemblies, vehicle parts, etc., can solve the problems of mold development cost and long cycle, height difference of decorative air ducts, standing height space limitation, etc. Achieve the effect of perfecting product chain structure, reducing development cost and cycle, and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

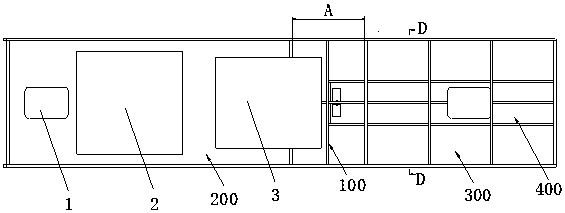

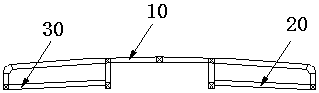

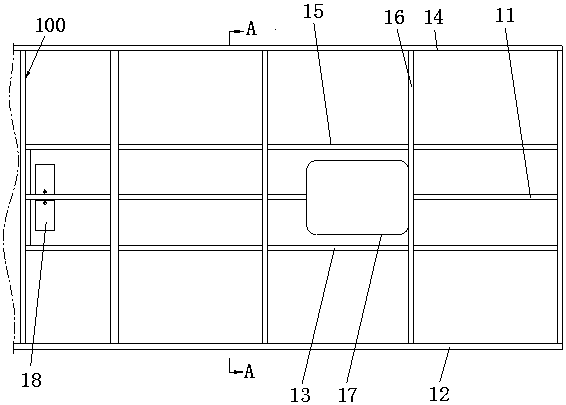

[0024] like figure 1 , figure 2 The roof frame structure of a single-layer roof combined with a two-stage stepper shown includes a first roof frame area 200 located in front of the center position 100 of the middle door and a second roof frame area 300 located behind the center position 100 of the center door. The first roof frame area 200 is a double-layer roof structure, the second roof frame area 300 is a single-layer roof structure in the middle aisle area 400, and the two sides of the middle aisle area 400 are double-layer roof structures. The air duct is in the same plane as the air duct 500 of the second roof frame region 300 . figure 1 The position of part A marked in is the position of the middle door, and the center position 100 of the middle door is the dividing line between the first roof frame area 200 and the second roof frame area 300, and the first roof f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com