Spreading shoe structure of quasi-rectangular shield pushing oil cylinder

A technology of propelling oil cylinders and rectangular shields, applied in mining equipment, earth-moving drilling, tunnels, etc., can solve the problems of large space occupation, high cost, complicated ball head installation, etc., to facilitate the overall installation, reduce manufacturing costs, shorten the Effect of installation length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

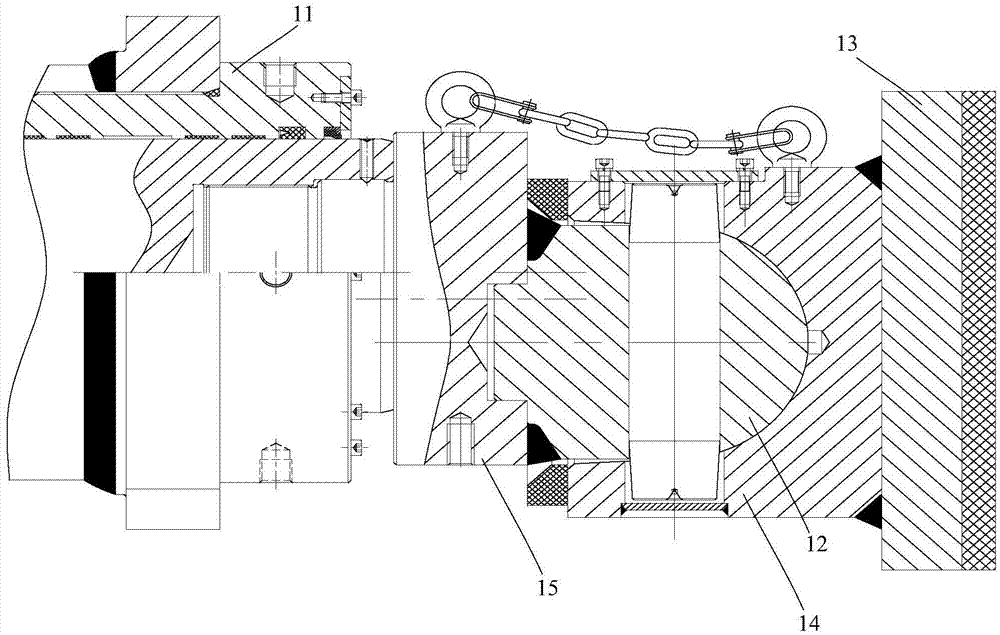

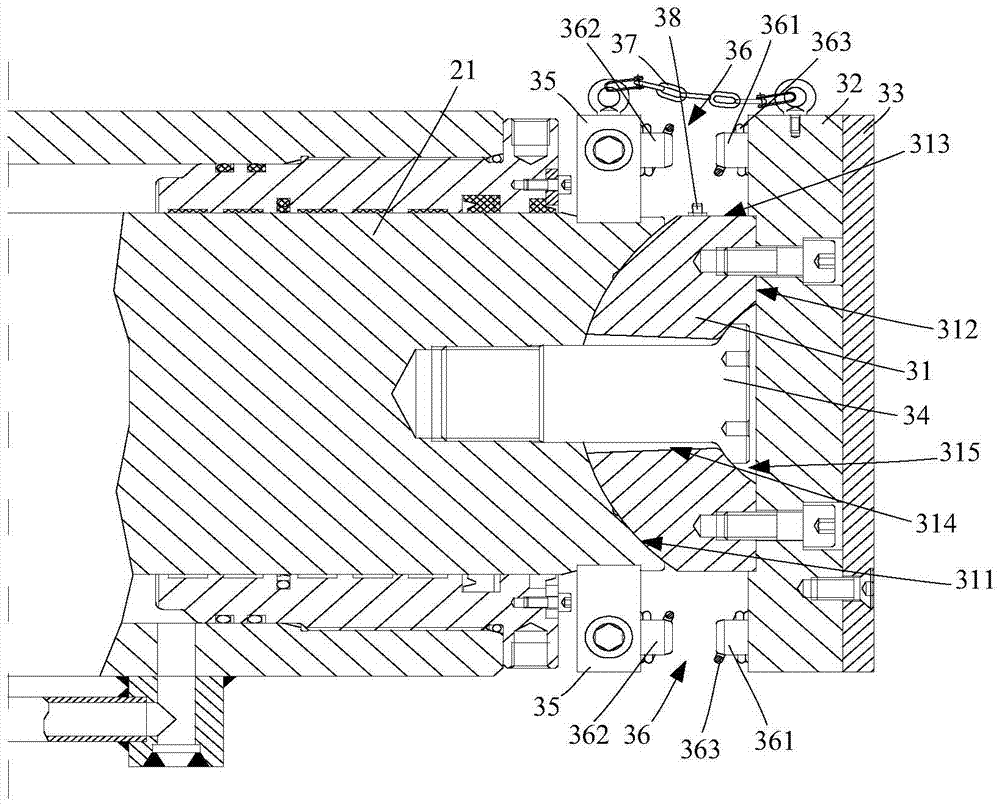

[0022] The invention provides a support shoe structure of a kind of rectangular shield machine propulsion cylinder, which is installed at the front end of the piston rod of the propulsion cylinder, and is used to transmit the push force of the propulsion cylinder to the shield machine. The support shoe structure of the similar rectangular shield propulsion cylinder of the present invention is designed as a hemispherical ball head, and the spherical surface is set corresponding to the end of the piston rod, and the mounting surface opposite to the spherical surface is directly connected to the top plate, which greatly reduces the The space occupied by the support shoe structure is reduced, and the installation length of the entire oil cylinder is shortened. The shortening of the installation length of the oil cylinder directly shortens the struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com